Operation Manual

54

A7 MIG Welder© Kemppi Oy 2018 1804

INTEGRATION GUIDE

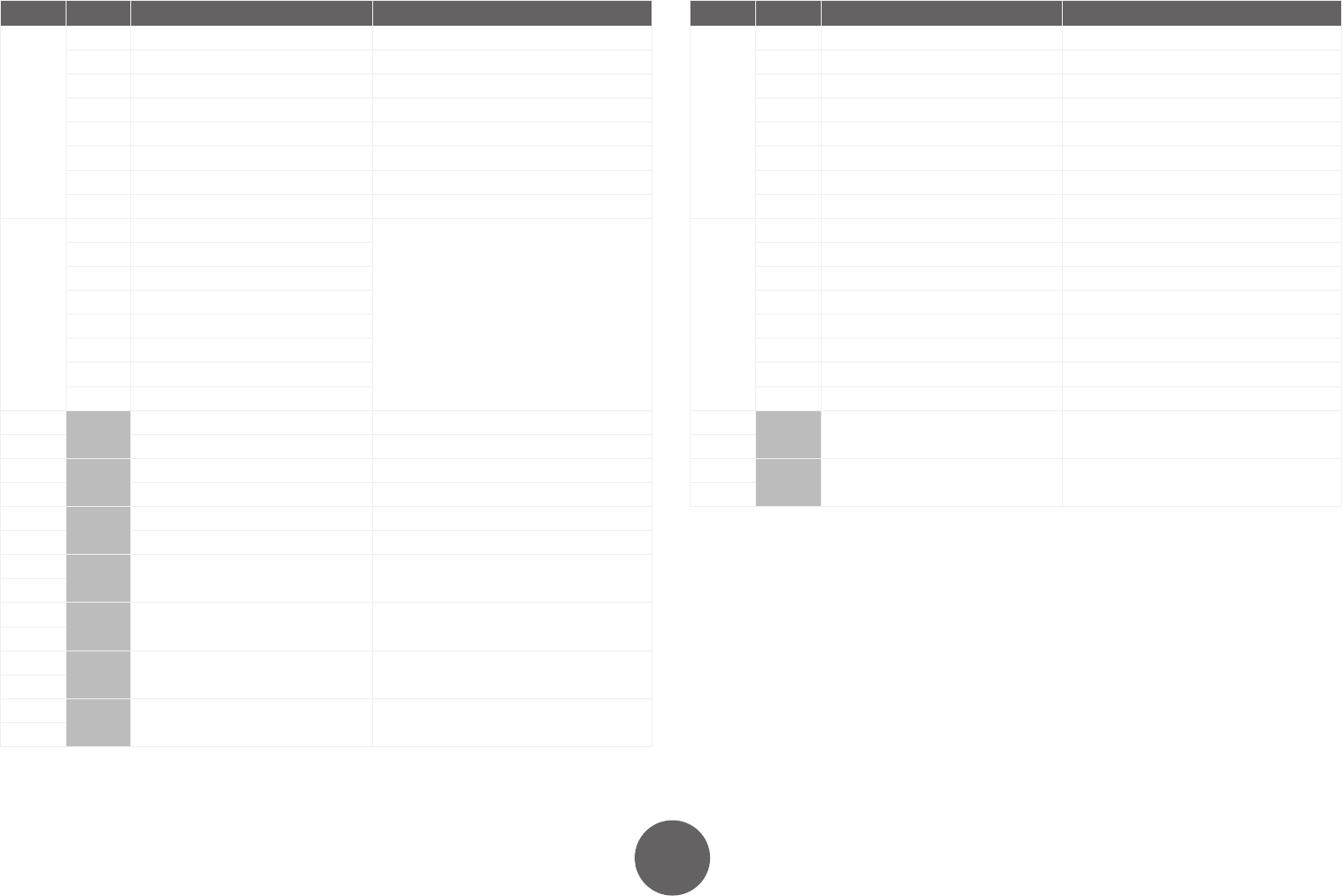

6.3.6 CUST1: Customer-specific table

Interface mode = 3. Table size = 16 bytes.

Byte Bit Control (Robot -> Welder) Status (Welder -> Robot)

0 0 StartWelding ArcOn (1)

1 WeldingAllowed AutoManual

2 OnlineControl CycleOn

3 (Not in use) ArcOn (2)

4 (Not in use) CollisionDetected

5 DigitalOutput1 Error

6 DigitalOutput2 Ready

7 DigitalOutput3 TouchSensed

1 0 GasBlow

ErrorNumber

1 WireInch

2 WireRetract

3 (Not in use)

4 TouchSensorOn

5 (Not in use)

6 (Not in use)

7 (Not in use)

2

MemoryChannel (Not in use)

3 (Not in use) (Not in use)

4

(Not in use) (Not in use)

5 (Not in use) (Not in use)

6

(Not in use) (Not in use)

7 (Not in use) (Not in use)

8

WireFeedSpeed WeldingCurrent

9

10

Voltage / FineTuning WeldingVoltage

11

12

(Not in use) (Not in use)

13

14

(Not in use) (Not in use)

15

6.3.7 CUST2: Customer-specific table

Interface mode = 5. Table size = 6 bytes.

Byte Bit Control (Robot -> Welder) Status (Welder -> Robot)

0 0 StartWelding ArcOn

1 AirBlow Error

2 GasBlow GasFlowOK

3 WireInch DigitalInput2 (Wire OK)

4 WireRetract AutoManual

5 DigitalOutput3 LocalRemote

6 OnlineControl Ready

7 DigitalOutput2 (Cleaning on) DigitalInput3 (Cleaning OK)

1 0 TouchSensorOn TouchSensed

1 MemoryChannel (bit 0) DigitalInput1

2 MemoryChannel (bit 1) DigitalInput4

3 MemoryChannel (bit 2) DigitalInput5

4 MemoryChannel (bit 3) PowerSourceReady

5 MemoryChannel (bit 4) CycleOn

6 MemoryChannel (bit 5) (Not in use)

7 MemoryChannel (bit 6) (Not in use)

2

WireFeedSpeed WeldingCurrent

3

4

Voltage / FineTuning WeldingVoltage

5