Operation Manual

32

A7 MIG Welder© Kemppi Oy 2018 1804

INTEGRATION GUIDE

5.2.3 Setting up scaling values

The A7 MIG Welder system supports value scaling between

the welding system and the robot for wire feed speed,

welding voltage, ne tuning, and welding current. This

scaling is required when the value range of the robot is

limited or the robot cannot otherwise directly handle the

values provided by the welding system.

The following digital robot interface functions can be

scaled:

• WireFeedSpeed control function

• Voltage control function

• FineTuning control function

• WeldingWireFeedSpeed status function

• WeldingVoltage status function

• WeldingCurrent status function

For more information on these functions, see Chapter 6,

“Digital robot interface I/O reference”.

To set up the scaling values, go to Welding settings >

Welding system > General robot settings.

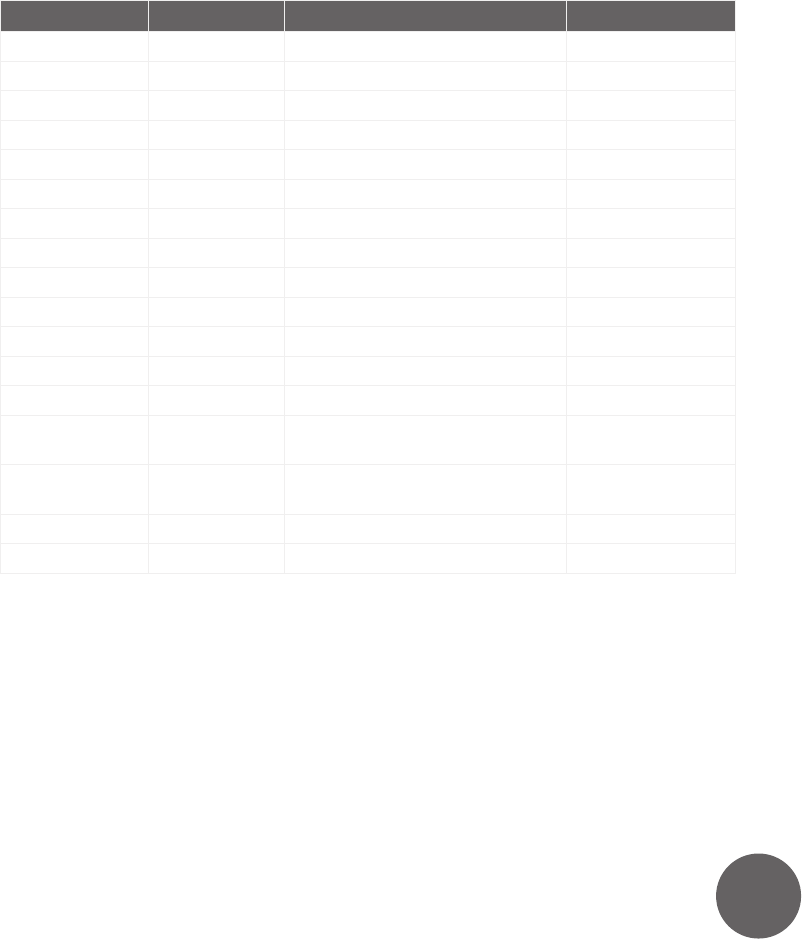

Table 5.1: Supported I/O tables

Interface mode I/O table name Description Table size (bytes)

0 (Not in use)

1 KEMPPI1 KempArc Pulse default table 8

2 (Not in use)

3 CUST1 Customer-specic table 16

4 (Not in use)

5 CUST2 Customer-specic table 6

6 CUST3 Customer-specic table 10

7 CUST4 Customer-specic table 10

8 (Not in use)

9 CUST5 Customer-specic table 12

10 (Not in use)

11 (Not in use)

12 (Not in use)

13 KEMPPI2 KempArc Pulse

Gate door switch alternative

8

14 KEMPPI3 KempArc Pulse

TAST support

10

15 KEMPPI4 A7 MIG Welder default table 16

16–99 (Reserved)