Operation Manual

53

A7 MIG Welder© Kemppi Oy 2018 1804

INTEGRATION GUIDE

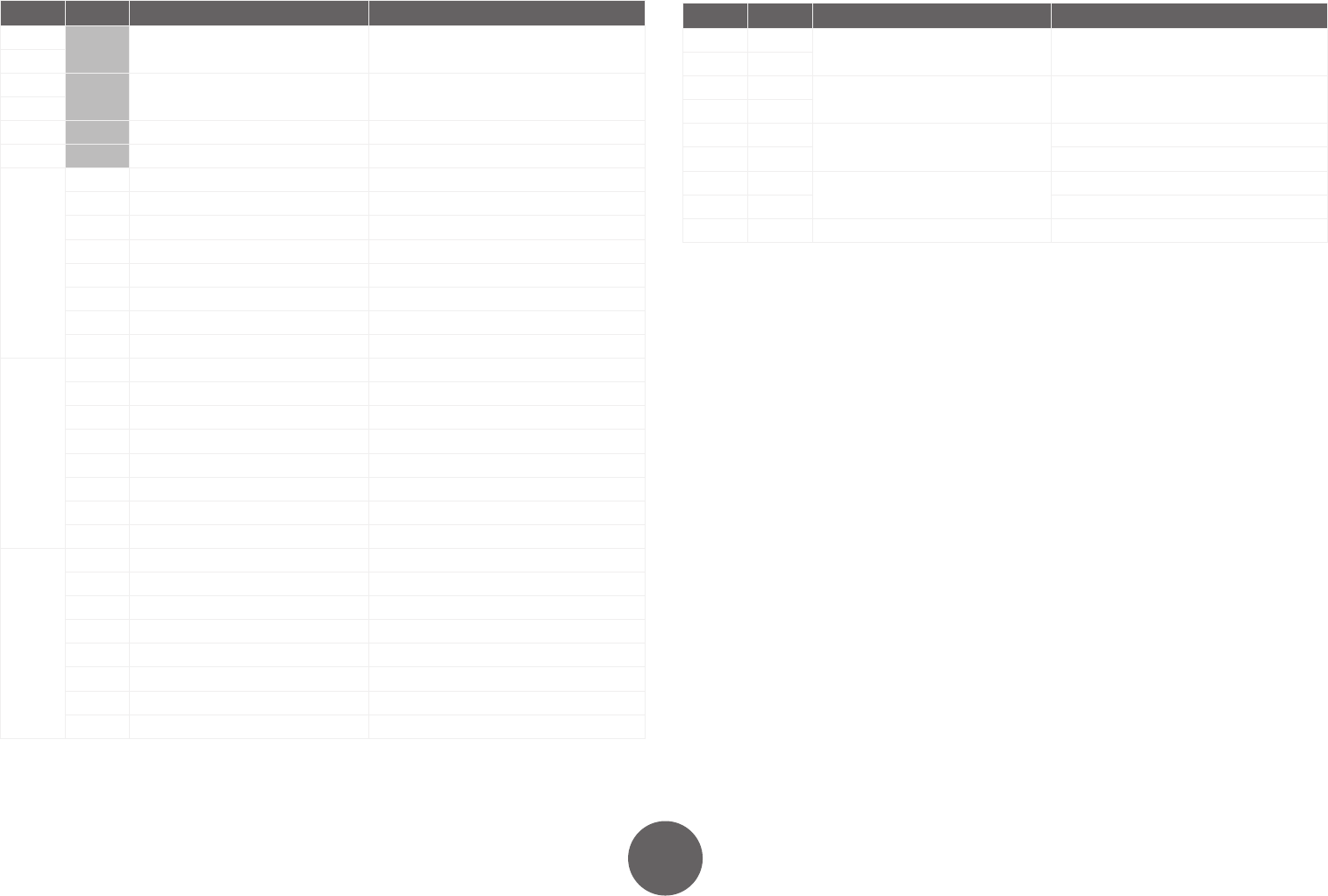

6.3.5 KEMPPI5: A7 MIG Welder table for pulse process control

Interface mode = 16. Table size = 18 bytes

Byte Bit Control (Robot -> Welder) Status (Welder -> Robot)

0

WireFeedSpeed WeldingCurrent

1

2

Voltage / FineTuning WeldingVoltage

3

4 MemoryChannel ErrorNumber

5 Dynamics WeldingWireFeedSpeed

6 0 StartWelding Ready

1 SimulationMode PowerSourceReady

2 WireInch CycleOn

3 WireRetract ArcOn

4 GasBlow GasFlowOk

5 AirBlow (Not in use)

6 TouchSensorToolSel (Not in use)

7 TouchSensorOn TouchSensed

7 0 OnlineControl GateDoorOpen

1 ErrorReset Error

2 WireFeederSelect CollisionDetected

3 Watchdog (Not in use)

4 HotStartOn (Not in use)

5 CraterFillOn (Not in use)

6 (Not in use) (Not in use)

7 (Not in use) (Not in use)

8 0 DigitalOutput1 DigitalInput1

1 DigitalOutput2 DigitalInput2

2 DigitalOutput3 DigitalInput3

3 DigitalOutput4 DigitalInput4

4 DigitalOutput5 DigitalInput5

5 DigitalOutput6 DigitalInput6

6 DigitalOutput7 DigitalInput7

7 DigitalOutput8 DigitalInput8

Byte Bit Control (Robot -> Welder) Status (Welder -> Robot)

9

PulseCurrent TAST

10

11

PulseBaseCurrent GasFlowRate

12

13

PulseFrequency

MotorCurrent

14 WeldingProcess

15

PulseLength

(Not in use)

16

17 (Not in use)