Operation Manual

50

A7 MIG Welder© Kemppi Oy 2018 1804

INTEGRATION GUIDE

6.3 I/O tables

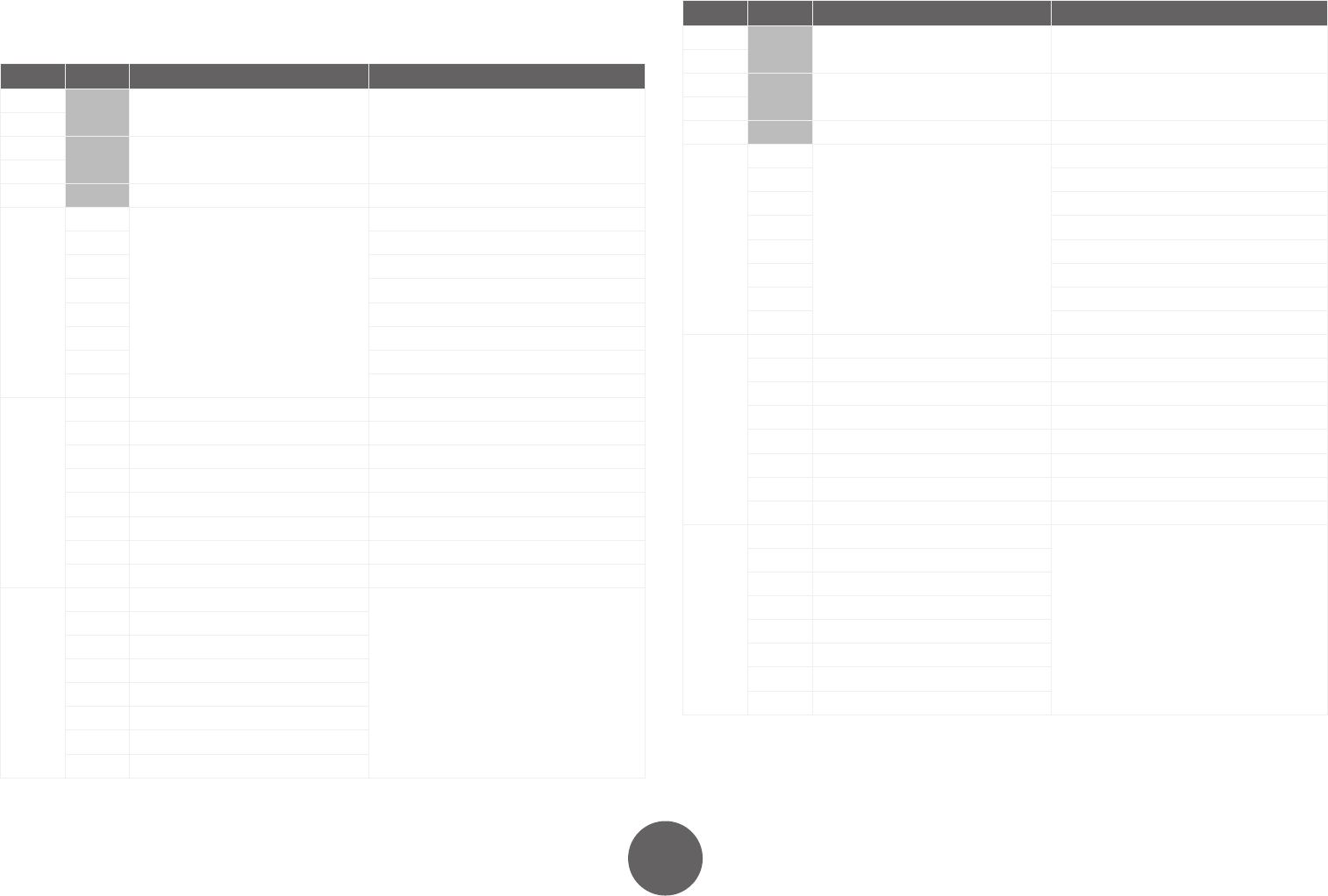

6.3.1 KEMPPI1: KempArc Pulse default table

Interface mode = 1. Table size = 8 bytes.

Byte Bit Control (Robot -> Welder) Status (Welder -> Robot)

0

WireFeedSpeed WeldingCurrent

1

2

Voltage / FineTuning WeldingVoltage

3

4 MemoryChannel ErrorNumber

5 0

Dynamics

CycleOn

1 ArcOn

2 TouchSensed

3 PowerSourceReady

4 Error

5 Ready

6 LocalRemote

7 AutoManual

6 0 StartWelding DigitalInput1

1 SimulationMode DigitalInput2

2 WireInch DigitalInput3

3 WireRetract DigitalInput4

4 GasBlow GateDoorOpen

5 TouchSensorToolSel DigitalInput6

6 TouchSensorOn CollisionDetected

7 OnlineControl GasFlowOk

7 0 Watchdog

WeldingWireFeedSpeed

1 ErrorReset

2 AirBlow

3 (Not in use)

4 (Not in use)

5 DigitalOutput1

6 DigitalOutput2

7 DigitalOutput3

6.3.2 KEMPPI2: KempArc Pulse customized table

Interface mode = 13. Table size = 8 bytes.

Byte Bit Control (Robot -> Welder) Status (Welder -> Robot)

0

WireFeedSpeed WeldingCurrent

1

2

Voltage / FineTuning WeldingVoltage

3

4 MemoryChannel ErrorNumber

5 0

Dynamics

CycleOn

1 ArcOn

2 TouchSensed

3 PowerSourceReady

4 Error

5 Ready

6 LocalRemote

7 AutoManual

6 0 StartWelding GateDoorOpen

1 SimulationMode DigitalInput2

2 WireInch DigitalInput3

3 WireRetract DigitalInput4

4 GasBlow DigitalInput5

5 TouchSensorToolSel DigitalInput6

6 TouchSensorOn CollisionDetected

7 OnlineControl GasFlowOk

7 0 Watchdog

WeldingWireFeedSpeed

1 ErrorReset

2 AirBlow

3 (Not in use)

4 (Not in use)

5 DigitalOutput1

6 DigitalOutput2

7 DigitalOutput3