Operation Manual

13

A7 MIG Welder© Kemppi Oy 2018 1804

INTEGRATION GUIDE

3.9 Fieldbus communication

This welding system supports the following eldbus

choices for communication between the welding

equipment and the welding robot.

Ethernet:

EtherNet/IP

EtherCAT

PROFINET

Modbus TCP

Others:

DeviceNet

PROFIBUS DP-V1

Modbus RTU

The choices are enabled by interchangeable Anybus

CompactCom M30 modules manufactured by HMS. See the

A7 MIG Welder Operating manual for the complete list of

modules and their order codes.

Do not remove or attach the eldbus module when the

power is switched on. Doing so could damage the module.

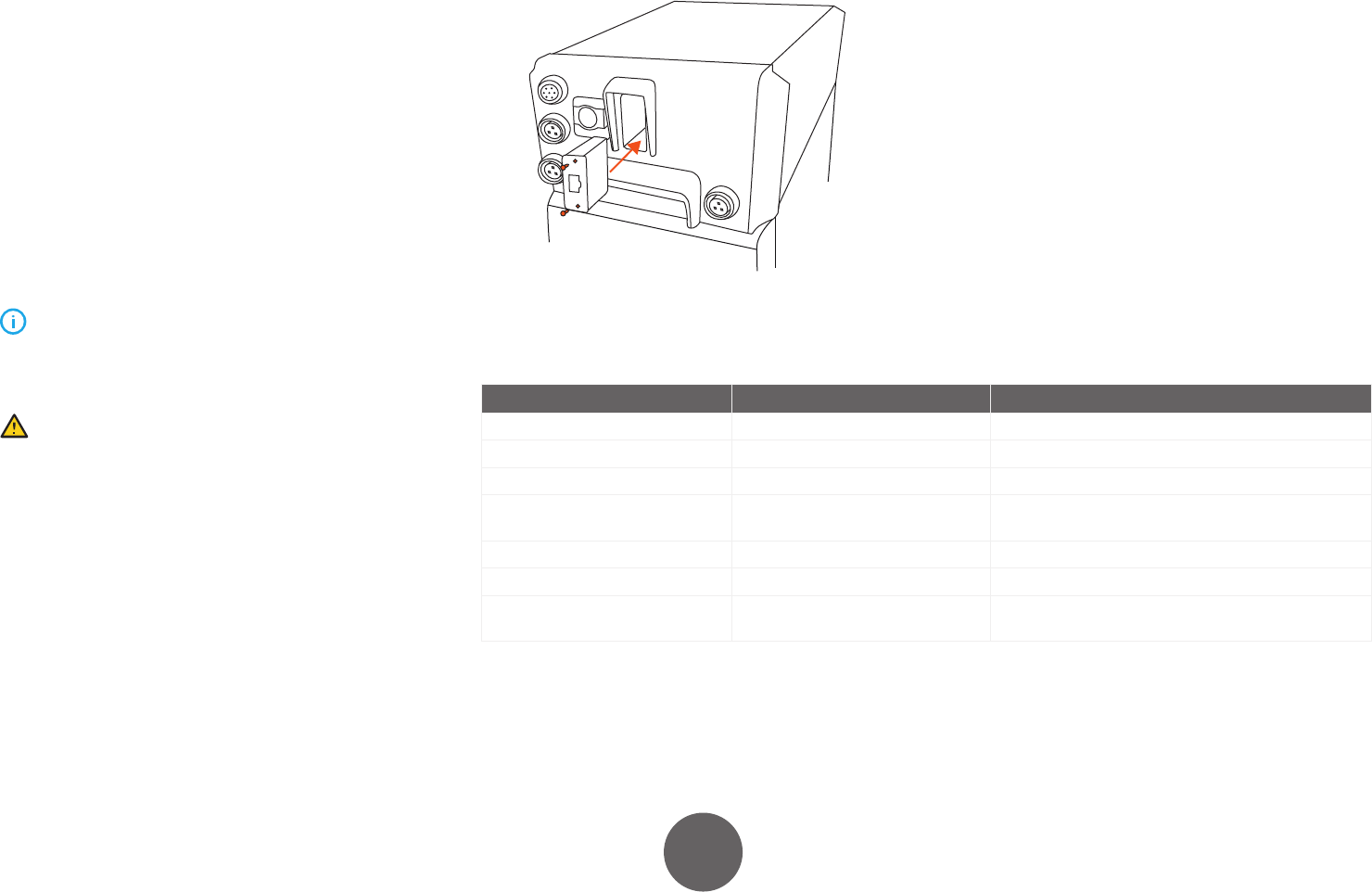

There is a connection slot for the module on the back of

the robot interface unit. Place the appropriate type of

Anybus module in the slot (see Figure 3.13, “Installing a

eldbus adapter”).

Ensure that it sits properly in its place.

Tighten the two screws on the module after you have

placed it into the slot. Connect a suitable eldbus cable to

the connector of the Anybus module and the other end of

the cable to the robot controller.

Figure 3.13: Installing a eldbus adapter

Table 3.2: Kemppi Oy vendor IDs and device description les

Fieldbus Vendor ID Device description le

EtherNet/IP 1-port and 2-port 1403 (integer) EDS (Electronic Data Sheet)

EtherCAT 00FE0001h (hexadecimal) ESI (EtherCAT Slave Information)

PROFINET 1-port and 2-port 0368h (hexadecimal) GSD (General Station Description)

Modbus TCP 1-port and 2-port ”Kemppi” (text) The Modbus standard does not feature a device

description le.

DeviceNet 1403 (integer) EDS (Electronic Data Sheet)

PROFIBUS DP-V1 0368h (hexadecimal) GSD (General Station Description XML)

Modbus RTU ”Kemppi” (text) The Modbus standard does not feature a device

description le.