Product Manual

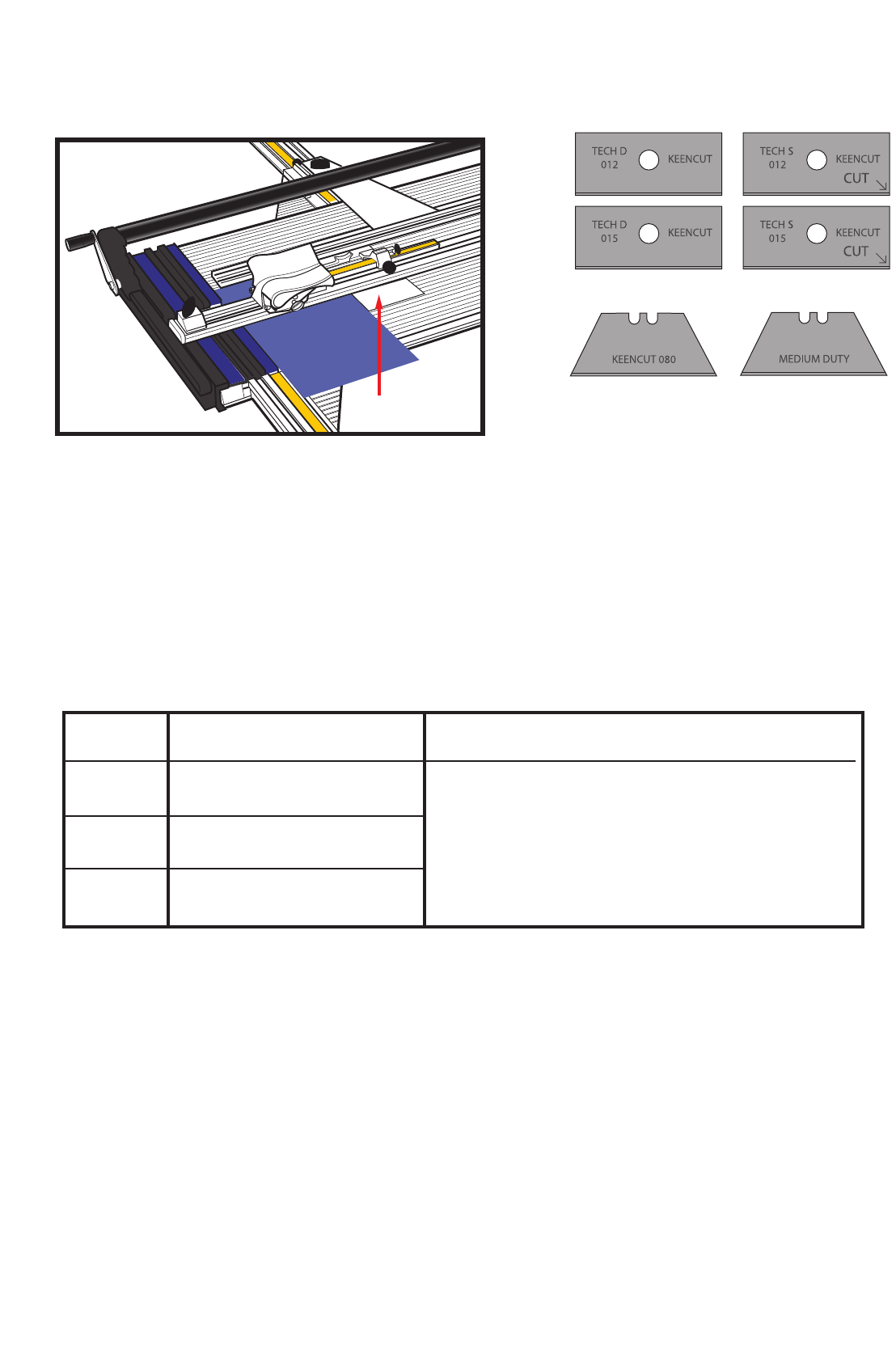

1 THE SLIPMAT is used under the matboard when bevel cutting, this ensures crisp clean cutting Make it from

standard matboard. Avoid using dense matboard such as black core.

Size - approximately 15cm (6”) wide and either the full cutting length of the Ultimat long, or at least 5cm (2”) longer

than the longest mat you are going to cut.

When using - ensur

e the white side is uppermost and replace it when the surface damage becomes obvious.

n BLADES are one of the most critical parts of the machine, in all cases the blade used should be the one most suited

to the job in hand - when bevel cutting a precision ground and honed blade is required with an oil free surface (many

blades are packed with an oil film to protect them) and the surface should be corrosion free.

The hardness and toughness of the blade is also critical.

All these factors add to the manufacturing cost of quality blades, however, the option to use inexpensive blades

leaves quality to chance and can increase wastage.

2 BEVEL CUTTING blades used on the Ultimat are rectangular and come in four varieties:-

Please Note: when using the T

ech S blades you can only use the one tip as indicated on the blade.

n BLADE DEPTH is critical when bevel cutting. Too deep and hooking will occur, too shallow and the blade will not

penetrate or meet at the corners. The tip of the blade should cut through the matboard and score the slipmat

about 0.5 - 1 mm (1/64” - 1/32”) deep. The method of adjustment is explained later.

n HOOKING is when a curved cut is produced at the beginning of a bevel cut. This is caused by the blade bending or

moving sideways when being pushed into the matboar

d, the blade then springs or moves back to its corr

ect position

as it begins to travel down the cut.

n PREVENTION is covered in the “Fault finding“ section.

3 VERTICAL CUTTING is carried out using either a standard trapezium shaped blade or the TECH D 012/015 blades.

The trapezium shaped blades are thicker (0.017”) and tend to distort less than the rectangular blades for

vertical cutting.

Generally (clip frames excepted), providing the edge is straight, square and clean the quality of finish of the cut is

less critical than with bevel cutting therefore the less expensive “medium duty utility” blade can be used, for better

results use “Keencut 080” blades.

Blade depth is important. The further the tip of the blade extends thr

ough the matboar

d the mor

e dif

ficult it is to cut.

There are a variety of blades supplied with the machine, all matboards behave differently and although the foregoing

offers general guidelines it is important to experiment to find the best blade for each type and thickness of board.

1

2

3

TECH D

012

TECH D

015

TECH S

012

TECH S

015

Double ground edge 0.012” thick

(knife edge)

Double gr

ound edge 0.015” thick

(knife edge)

Single ground edge 0.012” thick

(chisel edge)

Double gr

ound edge 0.015” thick

(chisel edge)

For general purpose cutting on most matboard

(bevel and vertical cutting)

As a general rule the TECH D 015 is better for thick soft materials and can be

used for vertical cutting, the TECH S blades are better for the harder boards

such as conservation board with the 012's being used for boards under 3mm

(1/8") thick and the 015 for those over 3mm (1/8") thick.

Owing to the wide variety of types and thickness of mat boards available the

information above is a guide only. It is important to carry out tests to select the

blade that gives the best performance for your circumstances..

If you require sample blades please contact Keencut direct and a small quantity

will be sent F.O.C.

3.2

Preparation 3.2

Know your Blades

SLIPMAT