Product Manual

Cutting Thick Mats

6.5 Cutting techniques 6.5

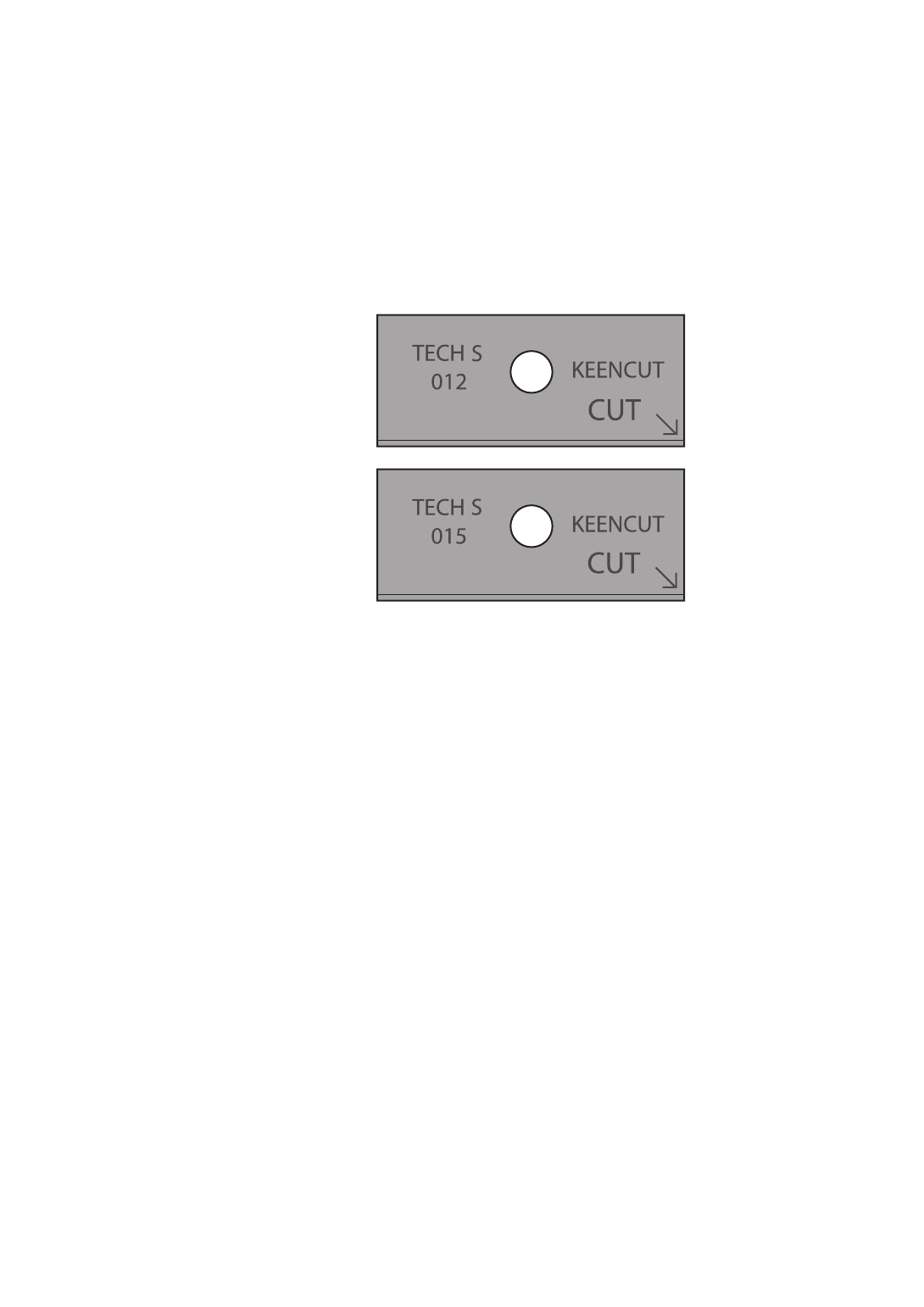

When cutting thick boards up to 3500 microns or 3.5mm (9/64”) use either the TECH S 012 or TECH S 015 blades,

the difference between these two blades is only their thickness. Different makes/types of board may give different

results so a little experimentation is worthwhile. Remember when using a TECH S blade that only one tip can be

used and that is shown by the arrow stamped on the blade.

If you find that both blades give acceptable results it would be better to use the TECH S 012, as the thinner blade will

be easier to pull through the board. Should there be any evidence of the blade bending or the tip breaking off change

to the TECH S 015.

Blade depth is even more important when cutting thick boards always check with a scrap piece of board that the

blade is only entering the slipmat by 0.5-1mm (1/64” to 1/32”).

Thick boards are generally cut in the same way as standard thickness boards but there are two techniques that can

be useful particularly with tough boards such as conservation quality.

n WHEN STARTING THE CUT

Slide the cutting head towards you until the start gauge has 5-10mm (1/4” -1/2”) to go before touching the edge of

the mat, pr

ess the blade about half way into the board and then cut until the start gauge touches, press the blade

in full depth then continue the cut.

This technique reduces the pressure required to insert the blade into the board by spreading it over two stages.

n AT THE END OF THE CUT

Some boards will show a scuff mark on the bevel which is due to the pressure the board puts onto the sides of the

blade as it is reversed out of the cut. This can be avoided by holding the blade in whilst lifting the long black handle

just enough to r

elease the board, then lift the blade holder to pull out the blade.

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920