Product Manual

6.6

Operation

Using & changing the twin wheel cutter

The twin wheel cutter is mounted on the upper cutting head and is used for cutting rigid materials

such as aluminimum composite panel and MDF up to 3mm (1/8”). Many other softer boards and

card can also be cut, trials should be carried out to ensure the desired quality of cut is obtained.

NOTE: The twin wheel cutter must be parked above the top level of the clamp when not in use

otherwise the cutter will interfere with the sightline strip if the clamp is operated.

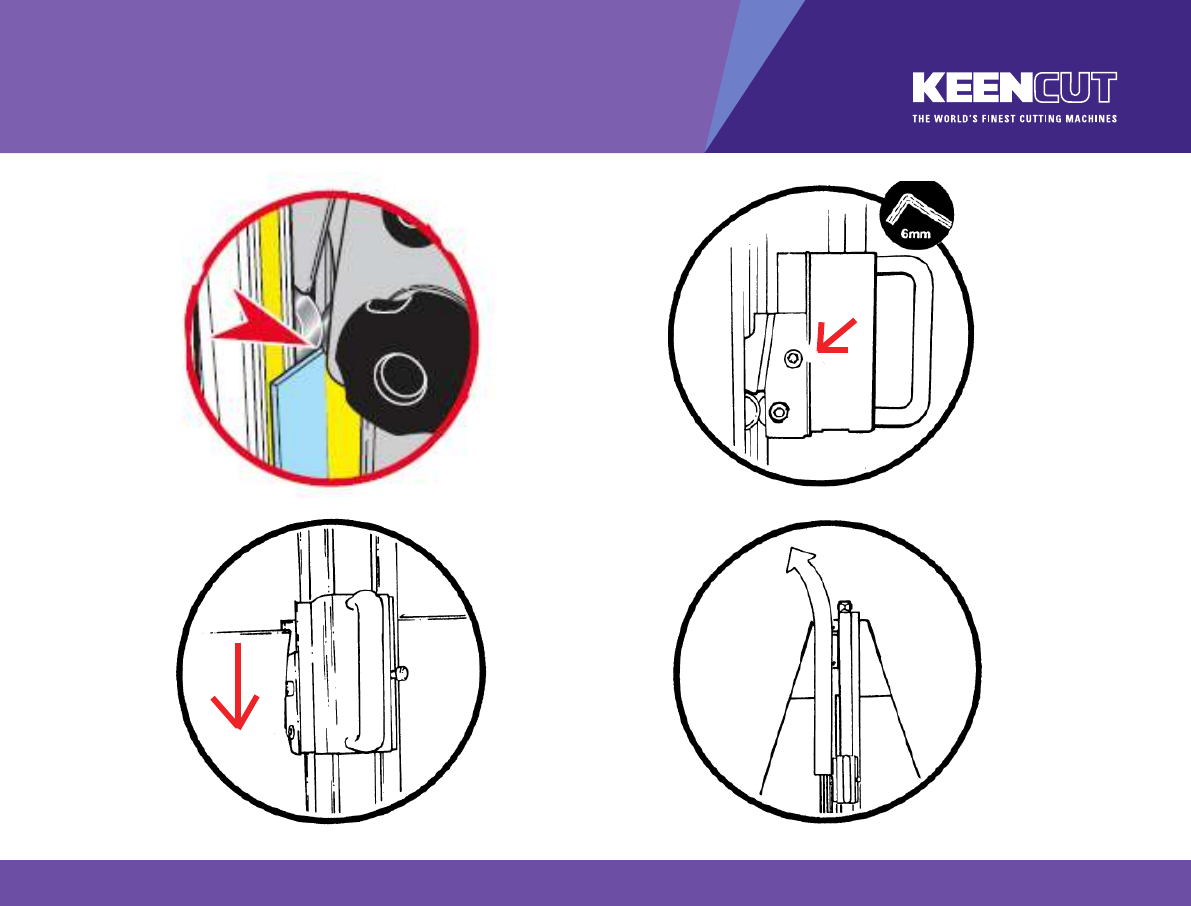

1. Position the material in the machine and apply the clamp.

2. Bring the twin wheel cutter down until it makes contact with the sheet edge and stop. Take a

rm grip and then push the cutter down through the material without stopping.

The cutting wheels generally last more than a year with average use but this is dependant upon daily

use and the material being cut. The signs the wheels are wearing out are:

• A rough nish predominantly on the right hand side of the cut, with aking on material such as

MDF.

• The bottom of the cut bursting out rather than being cut neatly.

• The board trying to turn under the clamp when being cut (also check the clamp pressure).

Changing the twin wheel cutter

Lock the cutting head at a convenient height using the white nylon locking screw.

3. Hold the twin wheel cutter and its guard to prevent them from falling and remove the screw

with a 6mm hexagon wrench.

4. Slide the cutter towards the top of the main body and lift out.

Replacement wheels or cutters are available from Keencut or your distributor.

❷

❹

❺