Product Manual

5.3

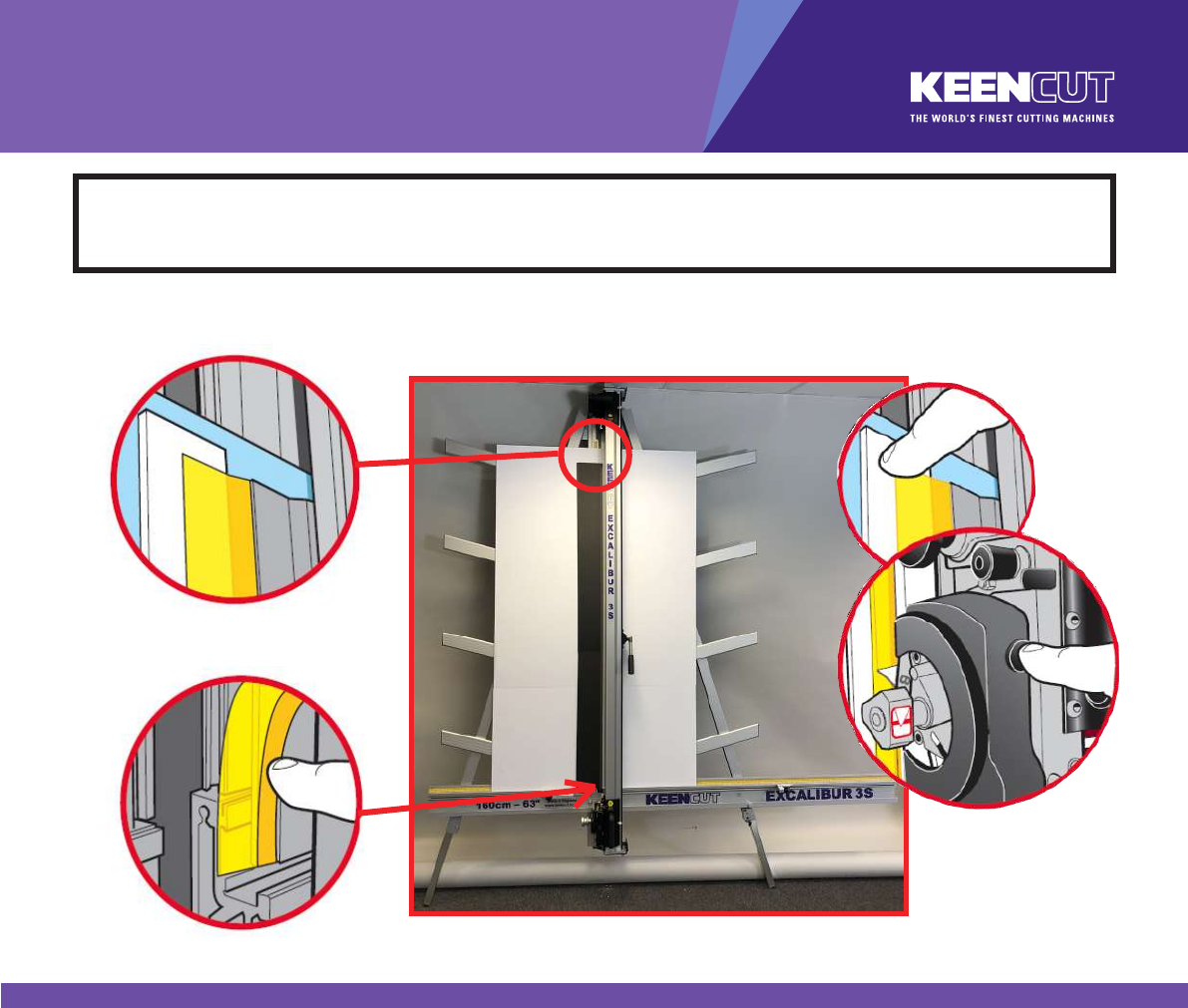

Calibration

Fitting the sightline strip

NOTE: The sightline strip is tted to your machine but may wear or get marked with use. A

spare strip is included with the machine, replacement strips are available from your distributor or

Keencut.

The sightline strip is xed to the clamp and then trimmed using the cutting blade to give an accurate

guide when cutting to trim lines, the edge of an image or pencil marks.

NOTE: Do not engage the twin wheel cutter until after reading its instructions for use in section 6.

Engaging the twin wheel cutter interferes with the sightline strip and can cause damage to it. A gap is

left in the sightline strip at a convenient height to enable the twin wheel cutter to be engaged.

1. Remove the worn sightline strip by peeling it o and clean any surplus adhesive with solvent

cleaner on a cloth. Remove the backing paper and starting at the bottom press the strip rmly

in the channel provided working upwards and cut o at a convenient height. Leave a gap of

18cm (7”) and then t the remainder of the strip.

2. Place a piece of rm board up to 6mm (1/4”) thick on the machine to bridge the gap running

down the back of the main body, this needs to be the full height of the clamp.

3. Place a piece of card or foam board 3-6mm (1/8”-1/4”) thick under the full length of the

exible part of the sightline strip, not under the aluminium clamp itself. Depress the

clamp handle so that the sightline strip is pressed at across the surface of the board.

4. Keep ngers clear and using a block or tool hold down the top left corner of the strip to start

the cut. With the turret rachet disengaged (scoring page 6) press the blade lightly on to the

surface of the sightline strip and score along the full length. Repeat and trim the sightline strip

in 2 or 3 cuts.

NOTE: If a board is not available to go the full length of the clamp use two or more pieces or trim

the strip in stages.

❶

❷

❸

❹