Installation & Operation Manual KBVF SERIES Chassis / IP-20 AC Drives Variable Speed / Soft-Start AC Motor Drive with Electronic Motor Overload Protection* Rated for 208-230 and 400/460 Volt 50 & 60 Hz 3-Phase & PSC** AC Induction Motors from 2 thru 5 HP Operates from 208/230 Volt and 400/460 Volt 50/60 Hz AC Line Input*** ACC U COMP TB1 MAX W MIN DEC/B MOTOR V CL L1 J1 CON1 A/M X1 X2 L3 CON3 J2 50/60Hz AC LINE L2 This Manual Covers Models KBVF-27, 29, 45, 48 See Safety Warning, on page 8.

TABLE OF CONTENTS Page Section 1 Quick-Start Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 2 Safety Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE OF CONTENTS (Continued) Page Figures 29 SIVFR Offset Trimpot (OFFSET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 30 Models KBVF-27, 29 Maximum Speed Trimpot (MAX) Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 31 Models KBVF-45, 48 Maximum Speed Trimpot (MAX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 32 Acceleration Trimpot (ACC) Range . . . . . . . . . . . .

Communication Port for Accessories and Programming: see Section 3.5, on page 10. L3 3-Phase Connection (Use L1, L2, L3) (Models KBVF-27, 29): see Section 9.1, on page 17. Single-Phase Connection (Use L1, L2) (Model KBVF-27 Only): see Section 9.1, on page 17. Motor Connection: see Section 9.3, on page 18. Motor For Two Times the Rated Motor RPM: see Section 6.1.2, on page 15. For 60 Hz or 50 Hz Motor Operation: see Section 6.1.1, on page 14.

L1 AC LINE L2 AC Line 3-Phase Connection: see Section 9.1, on page 17. Motor Connection: see Section 9.3, on page 18. Motor Ground (Earth): see Section 9.2, on page 17. W L3 Communication Port for Accessories and Programming: see Section 3.5, on page 10. Manual Start Switch Connection: see Section 9.6, on page 20. TB1 TB2 For Two Times the Rated Motor RPM: see Section 6.1.2, on page 15. CON3 J2 50/60Hz Automatic Start: See Section 6.2, on page 15.

+5V DBM NDBM TB1 PWR J5 -5V OV CON1 FWD REV SIG1 COM1 FIGURE 3 – SIVFR CONTROL LAYOUT OFFSET MAX TB2 K1 J4 K2 FAULT J1 J2 VOLT CUR RUN Sets the Run/Fault Relay Output Contacts for normally open or closed operation. Sets the drive for operation with a voltage or current input signal. Run/Fault Relay Output Contacts connection. Maximum Speed adjustment trimpot. Signal Offset adjustment trimpot. Signal Input, Direction Switch, and Main Speed Potentiometer connections. Power on LED.

1 QUICK-START INSTRUCTIONS Important – You must read these simplified instructions before proceeding. These instructions are to be used as a reference only and are not intended to replace the details provided herein. You must read the Safety Warning on, page 8, before proceeding. See Figures 1 – 3, on pages 4 – 6. Also see Section 4 — Important Application Information, on pages 13 and 14. WARNING! Disconnect main power when making connections to the drive. 1.

Models KBVF-45, 48 Unidirectional Speed Operation – Wire the potentiometer to Terminals “+5V” (high), “SIG1” (wiper), “COM1” (low), of Terminal Block TB1 on the SIVFR, as described in Section 9.4.2, on page 18. Be sure Jumper J1, on the SIVFR, is set to the “VOLT” position (factory setting). A jumper must be installed between Terminals “0V” and “FWD”, of Terminal Block TB1, in order for the drive to operate.

This product complies with all CE directives pertinent at the time of manufacture. Contact our Sales Department for Declaration of Conformity. Installation of a CE approved RFI filter is required. See RFI Filters & Chokes Selection Guide D-321 (Part No. A42027) for selection of filters to meet the Industrial or Residential Standard. Additional shielded cable and/or AC line cables may be required along with a signal isolator (SIVFR (Part No. 9597)).

3.2 PERFORMANCE FEATURES • Power Start™ – Provides more than 200% starting torque which ensures startup of high frictional loads. • Slip Compensation with Static Auto-Tune and Boost – Provides excellent load regulation over a wide speed range. • Speed Range – 60:1 3.3 PROTECTION FEATURES • Motor Overload (I2 t) with RMS Current Limit – Provides motor overload protection which prevents motor burnout and eliminates nuisance trips. UL approved as an electronic overload protector for motors. See Section 4.

• DIVF – Modbus Communication Module (Part No. 9568) – Allows the drive to communicate with PLCs, PCs, and HMIs with Modbus RTU protocol utilizing a serial communication cable. If a USB communication cable is required, purchase Part No. 19008. • Custom Software – All models can be factory programmed for applications which require special switching, timing, PLC functions, and GFCI operation – contact our Sales Department.

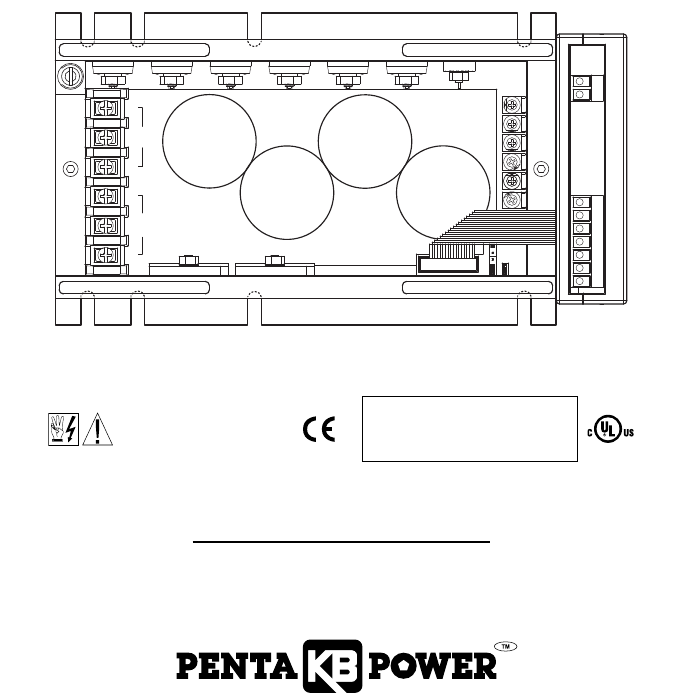

3.90 99.0 L1 AC LINE L2 L3 Models KBVF-29, 48 contain a built-in cooling fan on this end 0.2 5.1 7.00 178 (8 Places) 8.55 (Models KBVF-45, 48) 217 7.50 (Models KBVF-27, 29) 191 COMP ACC DEC/B MIN 4.70 119 0.5 12.7 W MAX MOTOR V CL 1.25 31.8 3.00 76.2 FIGURE 4 – MECHANICAL SPECIFICATIONS (INCHES/mm) & CONTROL LAYOUT CON1 J1 CON3 J2 50/60Hz 4.

FIGURE 5 – EXPANDED VIEW OF JUMPERS AND TRIMPOTS IMPORTANT APPLICATION INFORMATION 4.1 MOTOR WITH EXTERNAL FAN COOLING – Most totally enclosed fancooled (TEFC) and open ventilated 3phase AC induction motors will overheat if used beyond a limited speed range at full torque. Therefore, it is necessary to reduce motor load as speed is decreased. ACC COMP Adjustable Trimpots DEC/B Note: Some fan-cooled motors can be used over a wider speed range. Consult the motor manufacturer for details.

level of 160% of the rated drive current. The CL Trimpot is used to recalibrate the drive current from 60% thru 200%. The Power Start™ circuit provides an overshoot function that allows most motors to develop more than 200% of starting torque and breakdown torque. Standard I2 t is undesirable because it causes nuisance tripping. It allows a very high motor current to develop and will turn the drive off after a short period of time.

For 120 Hz output with 60 Hz motor, be sure Jumper J1 is set to the “60Hz” position and set Jumper J2 to the “X2” position. For 100 Hz output with 50 Hz motor, set Jumper J1 to the “50Hz” position and set Jumper J2 to the “X2” position. See Figure 10. 6.2 AUTOMATIC START (CON1) – The drive is factory set for Automatic Start (jumper installed onto CON1), as shown in Figure 11. CON1 is located on the lower PC board. The drive will automatically start when power is applied and a run command is given.

The enclosure should be large enough to allow for proper heat dissipation so that the ambient temperature does not exceed 45 °C (113 °F). Leave enough room to allow for AC line, motor connection, and other wiring that is required. See Figure 4, on page 12. When mounting the Main Speed Potentiometer, be sure to install the insulating disc between the potentiometer and the panel. Models KBVF-29, 48: 1. When mounting these drives in a vertical direction, the cooling fan must be on top. 2.

9 WIRING INSTRUCTIONS WARNING! Read Safety Warning, on pages 8 and 9, before using the drive. Disconnect main power when making connections to the drive. To avoid electric shock, be sure to properly ground the drive. Application Note – To avoid erratic operation, do not bundle the AC line and motor wires with each other or with wires from signal following, start/stop contacts, or any other signal wires. Also, do not bundle motor wires from multiple drives in the same conduit.

FIGURE 15 – MODELS KBVF-27, 29 MAIN SPEED POTENTIOMETER CONNECTION (UNIDIRECTIONAL OPERATION) MOTOR CONNECTION – Wire the motor to Terminals “U”, “V”, “W”. The terminals are located on the upper PC board. See Figure 14, on page 17. Motor cable length should not exceed 100 ft (30 m) – special reactors may be required – consult our Sales Department. Main Speed Potentiometer (Supplied) (Front View) Note: The drive is programmed to operate 3-phase AC induction motors.

FIGURE 18 – MODELS KBVF-27, 29 VOLTAGE FOLLOWING SIGNAL INPUT CONNECTION SIGNAL FOLLOWING CONNECTIONS – The drive output will linearly follow the analog signal input. 0 – 5 Volts DC (Isolated) Models KBVF-27, 29 Wire the isolated* 0 – 5 Volt DC signal input positive lead (+) to Terminal “P2” and the negative lead (–) to Terminal “P1”. The terminals are located on the lower PC board. With external circuitry, a 0 – 10 Volt DC analog signal can also be used. See Figure 18.

MANUAL START SWITCH CONNECTION (CON1) – The Manual Start Mode is used to manually start the drive or restart the drive (reset) if a fault has occurred. To operate the drive in the Manual Start Mode, remove the factory installed jumper on CON1 and install the 2-wire connector (supplied). CON1 is located on the lower PC board. The connector must be wired to a momentary switch or contact, as shown in Figure 21, on page 19.

For Forward Enable Operation, wire the switch to the white and black wires. For Reverse Enable Operation, wire the switch to the red and black wires. When the switch is closed, the drive will run. When the switch is opened, the drive will stop.

10 AC LINE FUSING This drive does not contain AC line fuses. Most electrical codes require that each ungrounded conductor contain circuit protection. Do not fuse neutral or ground connections. It is recommended to install a fuse (Littelfuse 326, Buss ABC, or equivalent) or a circuit breaker in series with each ungrounded conductor. Do not fuse motor leads. For the recommended fuse size, see Table 2, on page 11.

12.1 POWER ON (PWR) – The “PWR” LED will illuminate green when the AC line is applied to the drive. 12.2 STATUS LED (ST) – The “ST” LED is a tricolor LED which provides indication of a fault or abnormal condition. The information provided can be used to diagnose an installation problem such as incorrect input voltage, overload condition, and drive output miswiring. It also provides a signal which informs the user that all drive and microcontroller operating parameters are normal.

FIGURE 31 – MAXIMUM SPEED TRIMPOT MODELS KBVF-45, 48 on page 24. 13.3 ACCELERATION (ACC) – Sets the amount of time for the motor to accelerate from zero speed to full speed. The ACC Trimpot is factory set to 1.5 seconds. For longer acceleration time, rotate the ACC Trimpot clockwise. For more rapid acceleration, rotate the ACC Trimpot counterclockwise. See Figure 32.

13.6 BOOST (DEC/B) – When the drive is set for 50 Hz Motor Operation (Jumper J1 installed in the “50Hz” position), the DEC/B Trimpot automatically becomes the adjustable BOOST Trimpot. Most 60 Hz motors conforming to NEMA standards can operate from a preset Volts/Hz curve. 50 Hz motors, however, generally differ widely in their characteristics. Therefore, it is necessary to have adjustable Boost to obtain maximum motor performance. To increase the boost, rotate the BOOST Trimpot clockwise.

Note: This adjustment must be made within 6 seconds or the I2 t Trip will occur. FIGURE 39 – CL TRIMPOT RANGE MODEL KBVF-48 1. Connect an AC RMS ammeter in series with one motor phase. 10.3 7.6 13.3 5.0 15.5 2. Set the CL Trimpot fully counterclockwise. 3. Adjust the speed setting to 30% of full speed. 4. Lock the motor shaft and adjust the CL Trimpot to 160% of the motor nameplate rated current. CL (Shown Factory Set to 13.3 Amps) Example: A 2 HP motor has a full load current rating of 5.2 Amps.

– NOTES – 27

LIMITED WARRANTY For a period of 18 months from the date of original purchase, KB Electronics, Inc. will repair or replace without charge, devices which our examination proves to be defective in material or workmanship. This warranty is valid if the unit has not been tampered with by unauthorized persons, misused, abused, or improperly installed and has been used in accordance with the instructions and/or ratings supplied. The foregoing is in lieu of any other warranty or guarantee, expressed or implied.

RECONDITIONING THE BUS CAPACITORS If this drive has been in storage for over one year it is necessary to recondition the power supply bus capacitors. To recondition the bus capacitors, apply the AC Line, with the drive in the Stop Mode, for a minimum of one hour. Not following this procedure will cause the bus capacitors to fail. (A40194) – Rev.