User Guide

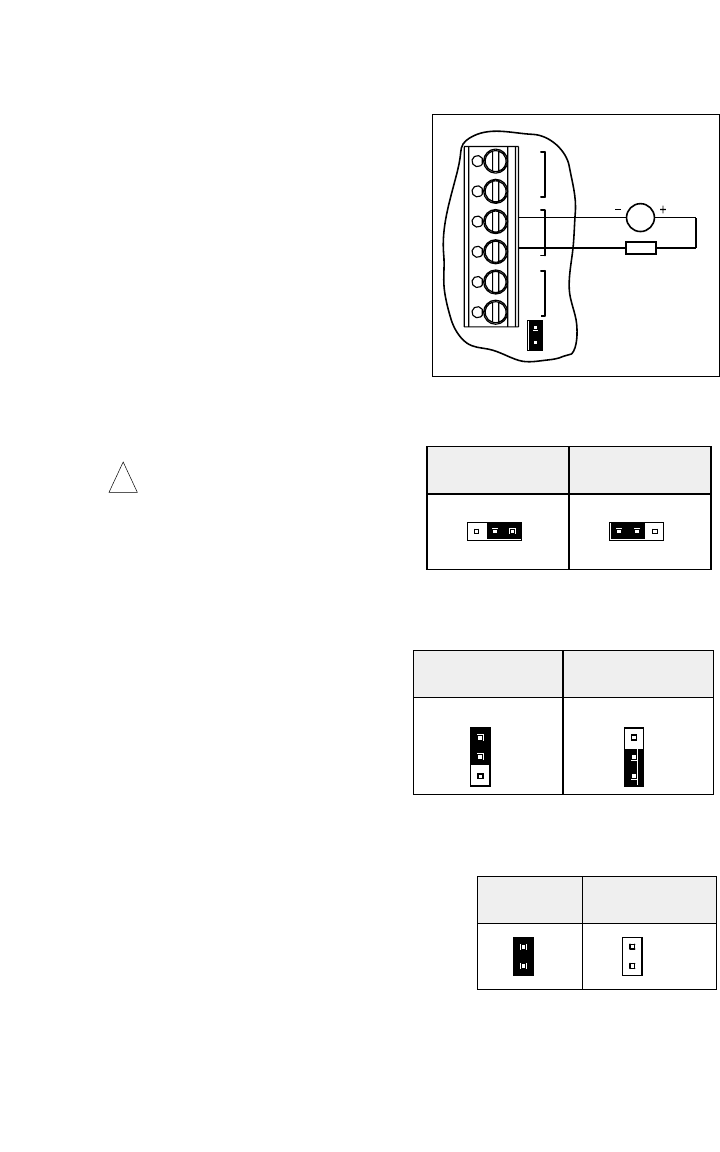

E. Run Relay Output Mode Selection (J5)

– Jumper J5 is factory set to “NO” position

for normally open relay output at TB4. For

normally closed relay output, set jumper

J5 to “NC” position. See Figure 20.

F. Stop Switch Type Selection (J6) –

Jumper J6 is factory set to the “NO” position

for a normally open stop switch, as used on

the front cover. If a remote normally closed

stop switch is used, set Jumper J6 to the

“NC” position. If a remote normally open

stop switch is used, set Jumper J6 to the

“NO” position. See Figure 21.

G. Enable Selection (J7) – Jumper J7 is fac-

tory installed to enable the control. If con-

necting Enable contacts to Terminals EN1

and EN2 of Terminal Block TB3, remove

Jumper J7. See Figure 22.

V. MOUNTING INSTRUCTIONS

Warning! The KBPW-240D is not

designed to be used in an explo-

sion-proof application.

It is recommended that the control be mount-

ed vertically on a flat surface with adequate

ventilation. Leave enough room below the

control to allow for AC line, motor connec-

tions, and any other wiring. Although the

control is designed for outdoor and wash-

down use, care should be taken to avoid

extreme hazardous locations where physi-

cal damage can occur. If the control is

mounted in a closed, unventilated location,

allow enough room for proper heat dissipa-

tion. If operating the control at full rating, a

minimum enclosure size of 12”W x 24”H x

12”D is required. See Figure 2, on page 5.

The KBPW-240D is designed with a hinged

case so that when the front cover is open,

all wiring stays intact. To open the cover, the four

screws must be loosened so they are no longer

engaged in the case bottom. After mounting and

wiring, close the cover and make sure that wires will

not get caught or crimped as the cover is closed.

Tighten all four cover screws so that the gasket is

slightly compressed.

Do not over tighten.

VI. OPERATION

Caution!

It is recommended that the bus capacitors

be reconditioned if this product has been in storage for over one year. To recondition the capac-

itors, apply the AC line, with the drive in Stop Mode, for a minimum of one hour.

After the control has been properly set up (jumpers set to desired positions and wiring com-

pleted), the startup procedure can begin. If AC power has been properly brought to the con-

trol, the ON and STOP LEDs will be illuminated. Before starting, be sure the main speed

12

ENABLEEN

J7

DC TACH-GENERATOR

RT

EN1

EN2

T-

T+

TACH

K2

RELAY

K1

TB3

G

FIGURE 19 – DC TACH-GENERATOR

WITH ADDITION OF RT

!

J5 Set for Normally Open

(NO) Output Contacts

(Factory Setting)

J5 Set for Normally Closed

(NC) Output Contacts

NC NO

J5

J5

NONC

FIGURE 20 – RUN RELAY OUTPUT

MODE SELECTION

J6 Set for

Normally Open Stop Switch

(Factory Setting)

J6 Set for

Normally Closed Stop Switch

STOP

NO

NC

J6

STOP

NO

NC

J6

FIGURE 21 – STOP SWITCH

TYPE SELECTION

J7 Installed to

Enable the Control

(Factory Setting)

J7 Removed to

Connect Enable Contacts

EN

J7

EN

J7

FIGURE 22 – STOP SWITCH

TYPE SELECTION