User Guide

11

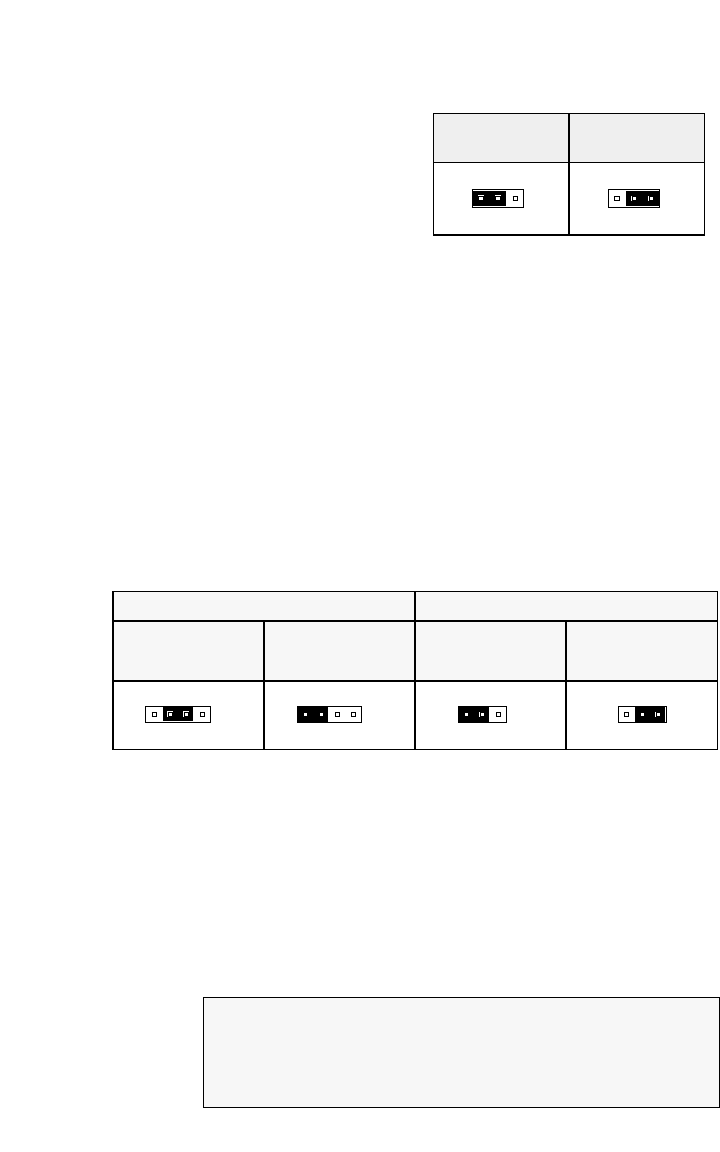

C. Timed and Non-Timed Current Limit

Selection (J3) – Jumper J3 is factory set

to “TCL” position for timed current limiting

operation. See Figure 17. For non-timed

current limiting operation, set jumper J3

to “NTCL” position.

TCL (Timed Current Limit) – When

Jumper J3 is in the “TCL” position, the

control will go into “STOP” after it is in

overload for a predetermined amount of

time (set by the TCL trimpot).

Resetting the Control After TCL – To reset the control after it has gone into TCL, momen-

tarily set the Start/Stop switch to “START” position or disconnect and reconnect the AC line.

If an On/Off AC Line Switch is installed, set it to “OFF” position and then back to “ON” posi-

tion. If the Start switch is jumpered (START and COM terminals connected), the control

must be restarted by disconnecting and reconnecting the AC line.

NTCL (Non-Timed Current Limit) – When jumper J3 is set to “NTCL” position, the control

will not go into “STOP” after it is in overload.

Note: TCL trimpot will have no affect when jumper J3 is in “NTCL” position.

D. DC Tach-Generator Voltage Selection (J1 and J4) – For a tach-generator wired to TB3,

set jumper J1 to “T” position. See Figure 18. Jumper J4 is factory set to “7V” position for 7

Volt per 1000 RPM tach-generators wired to TB3. For a 50 Volt per 1000 RPM tach-gener-

ator, set jumper J4 to “50V” position.

Note: When using a tach-generator, the IR trimpot should be set fully counterclockwise.

Note: The tach-generator input is designed for 7 Volt or 50 Volt per 1000 RPM tach-gen-

erators used with 1800 RPM motors. For tach-generators other than 7 Volt or 50 Volt per

1000 RPM or for motors other than 1800 RPM, an external 1/2 watt resistor (RT) must be

used. Install R

T in series with the tach-generator as shown in Figure 19, on page 12.

Jumper J4 must be set to “7V” position.

The value of RT in Ω can be calculated using the following formula:

RT = (1.46 x VT x S) - 19,000

Where VT is the tach-generator voltage (in Volts per 1000 RPM) and S is the base speed of

the motor (in RPM).

J3 Set for TCL Mode

(Timed Current Limit)

(Factory Setting)

J3 Set for NTCL Mode

(Non-Timed Current Limit)

TCL NTCL

J3

J3

NTCLTCL

FIGURE 17 – CURRENT LIMIT

MODE SELECTION

50V

7V7V

50V

90V

180V

T

J1

J4 J4

90V

J1

180V

T

J1 Set for 90 Volt Motors

(Factory Setting)

J4 Set for 7V per 1000RPM

Tach-Generator Input

(Factory Setting)

J4 Set for 50V per 1000RPM

Tach-Generator Input

J1 Set for

Tach-Generator Input

Jumper J1 Settings Jumper J4 Settings

FIGURE 18 – DC TACH-GENERATOR VOLTAGE SELECTION

Suppose you have a 20 Volt per 1000 RPM tach-generator with a 3600 RPM motor:

RT = (1.46 X 20 X 3600) - 19000 = 86120Ω.

Choose the closest 1/2W resistor value, which is 82000Ω (82kΩ) or 91000Ω (91kΩ).

Readjustment of the MAX trimpot may be necessary to achieve the desired maximum

output voltage.

Example: