Installation Instructions

System schemes

6 720 645 817 (2010/09)

12

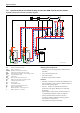

1.5 System scheme 5: two mixed heating circuits, one DHW circuit, low loss header

Hydraulic scheme with controller (schematic diagram)

Fig. 5

AF Outside temperature sensor

CUx Boiler control unit

FW 200 Weather-compensated controller

HP Heating circuit pump (primary circuit)

IPM 1 Load switching module for one heating circuit

IPM 2 Load switching module for two heating circuits

LP Cylinder primary pump

M

1,2

3-way mixer

MF

1,2

Mixer circuit temperature sensor

P

1,2

Heating circuit pump (secondary circuit)

SF Cylinder temperature sensor

ST ... DHW cylinder

TB

1,2

Temperature limiter

VF Common flow temperature sensor

ZP DHW circulation pump

1 Module position: on the heat source

3 Module position: on the wall

Heating system components

• Suprapur gas condensing boiler for balanced flue

operation

• Two mixed heating circuits

• DHW cylinder

• Weather-compensated controller

Features

• Generally, we would recommend the installation of a

low loss header on site to ensure reliable transfer of

the required heating output.

• The FW ... weather-compensated controller is

preferred for its higher utilisation of condensing

technology.

• Determine the system water content and select a

corresponding expansion vessel (Æ page 39).

• Install a mechanical safety limiter (TB 1) in

accordance with the underfloor heating system

manufacturer's instructions.

• Install safety assembly to DIN 1988.

Function description

The heating circuits are regulated by an FW 200

weather-compensated controller. This always requires

the IPM 1 and IPM 2 load switching modules. A 2-wire

BUS system enables communication between the boiler

control unit, the controller and the load switching

modules.

6 720 643 417-06.1O

AF

T

T

M

M2

P2

MF2

TB2

LP

VF

1

3

IPM 1

CUx

FW 200

3

3

IPM 2

ZP

SF

ST ...

Suprapur

KBR 120-280

HP

T

T

M

M1

P1

MF1

TB1