Operating Manual Owner manual

Table Of Contents

- Operating overview

- 1 Brief description

- 2 Identifying the device version

- 3 Mounting

- 4 Electrical connection

- 5 Startup of the device

- 5.1 Display and control elements

- 5.2 Setting the display after device is switched on

- 5.3 Selecting and editing parameters (plausibility requirement for input values)

- 5.4 Canceling edit

- 5.5 Acknowledging alarms using the reset key (for temperature limiter STB only)

- 5.6 Acknowledgement of alarms using the binary input (for temperature limiter STB only)

- 5.7 Functional test

- 5.8 Seal device

- 6 Safety Manual

- 6.1 Brief description

- 6.2 Safety temperature monitor (STW)

- 6.3 Safety temperature limiter (STB)

- 6.6 Connection possibilities of the sensors (SIL)

- 6.7 Standards and definitions

- 6.8 Safety-related parameters related to the temperature monitoring unit

- 6.9 Determining the Safety Integrity Level (SIL)

- 6.10 Determining the achieved Performance Level (PL)

- 6.12 Performance Level

- 6.13 Relationship between the Performance Level (PL) and the Safety Integrity Level (SIL)

- 6.14 Other applicable device documentation

- 6.15 Behavior during operation and in the event of a fault

- 6.16 Regular tests

- 6.17 Intrinsic safety according to DIN EN 60079-11

- 6.18 Monitoring of potential ignition sources according to DIN EN 50495 and DIN EN 13463- 6

- 6.19 Certificates

- 7 ATEX

- 7.1 Intended use

- 7.2 Identification markings according to ATEX directive 94/9/EC:

- 7.3 Meaning of the letter X in the type test certificate

- 7.4 Associated intrinsically safe electrical apparatus according to EN 60079-11

- 7.5 Safety device according to EN 50495

- 7.5.1 Temperature monitoring unit based on ignition protection "e" – increased safety according to EN 60079-7

- 7.5.1.1 Function of increased safety

- 7.5.1.2 Application in the 1-sensor variant

- 7.5.1.3 Application in the 2-sensor variant

- 7.5.1.4 Application of temperature transmitters

- 7.5.2 Minimum overpressure monitoring for static pressurized enclosure on the basis of ignition protection "p", pressurized enclosure according to EN 60079-2

- 7.5.2.1 Function of the static pressurized enclosure

- 7.5.2.2 Safety device for static pressurized enclosure

- 7.5.2.3 Application as safety device for static pressurized enclosure

- 7.6 Monitoring of potential ignition sources "b" according to EN 13463-6

- 8 Configuration level

- 9 Technical data

- 9.1 Analog inputs

- 9.2 Analog output

- 9.3 Binary input

- 9.4 Relay outputs

- 9.5 Measuring circuit monitoring

- 9.6 Voltage supply

- 9.7 Test voltages according to EN 60730, Part 1

- 9.8 Electrical safety

- 9.9 Environmental influences

- 9.10 Case

- 9.11 Approvals/approval marks

- 9.12 Important information for the probes in Chapter 9.13 to Chapter 9.15

- 9.13 Probes for the operating medium air

- 9.14 Probes for water and oil

- 9.15 Probes for air, water, and oil

- 10 Setup program

- 11 Alarm messages

- 12 Error messages

- 13 What to do, if ...

- 14 Information for devices with extra code 062 GL

- 15 Behavior of outputs

8 Configuration level

89

2013-04-01

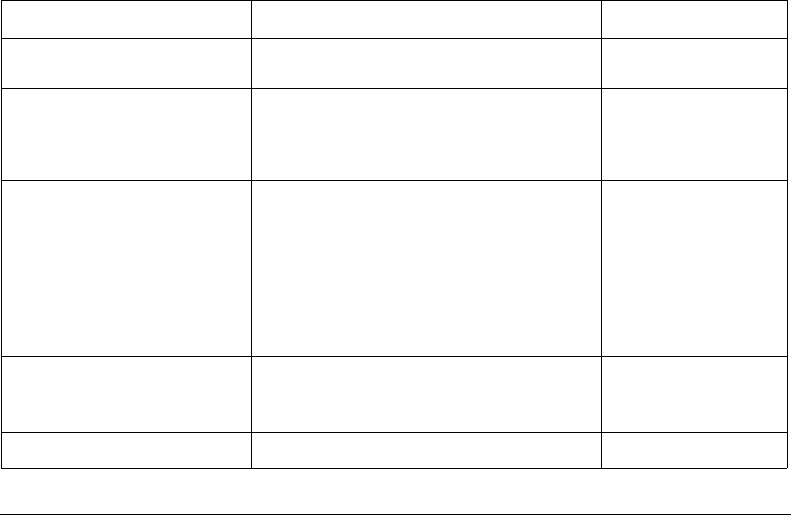

Parameter Comment

Value range

(factory setting in bold)

8.2.3 Offset 1

Using Offset1, a measured value at the analog input

can be corrected by the value entered over the entire

measuring range.

-999.9 to 0.0 to +999.9

8.2.4 Resistivity 1

Analog-input1 lead wire resistance

in 2-wire circuit

This value is used to compensate the resistance of the

probe line and depends on the line length.

Enter the ohmic resistance of the probe line here to

achieve the best possible temperature measurement.

0.0 to 30.0 ohm

8.2.5 Filter time 1

Time constant of the digital input filter

2nd order for analog input 1

If the input signal changes suddenly, approx. 26 % of

the change is recorded following a period that corre-

sponds to the filter time constant dF (2 × dF: approx.

59 %; 5 × dF: approx. 96 %).

Value 0 means: filter switched off

If the filter time is long:

- Interfering signals are better absorbed

- Measured value display responds more slowly to

changes

0.0 to 0.6 to 100 sec

8.2.6 Scaling start 1

Important information: This setting only occurs if the

sensor type 1 was set to 4 to 20 mA.

Here, the user selects which value (i.e. pressure)

should be displayed at 4 mA.

-9999 to 0 to +9999

8.2.7 Scaling end 1

Here, the user selects which value (i.e. pressure)

should be displayed at 20 mA.

-9999 to 100 to +9999