Operating Manual Owner manual

Table Of Contents

- Operating overview

- 1 Brief description

- 2 Identifying the device version

- 3 Mounting

- 4 Electrical connection

- 5 Startup of the device

- 5.1 Display and control elements

- 5.2 Setting the display after device is switched on

- 5.3 Selecting and editing parameters (plausibility requirement for input values)

- 5.4 Canceling edit

- 5.5 Acknowledging alarms using the reset key (for temperature limiter STB only)

- 5.6 Acknowledgement of alarms using the binary input (for temperature limiter STB only)

- 5.7 Functional test

- 5.8 Seal device

- 6 Safety Manual

- 6.1 Brief description

- 6.2 Safety temperature monitor (STW)

- 6.3 Safety temperature limiter (STB)

- 6.6 Connection possibilities of the sensors (SIL)

- 6.7 Standards and definitions

- 6.8 Safety-related parameters related to the temperature monitoring unit

- 6.9 Determining the Safety Integrity Level (SIL)

- 6.10 Determining the achieved Performance Level (PL)

- 6.12 Performance Level

- 6.13 Relationship between the Performance Level (PL) and the Safety Integrity Level (SIL)

- 6.14 Other applicable device documentation

- 6.15 Behavior during operation and in the event of a fault

- 6.16 Regular tests

- 6.17 Intrinsic safety according to DIN EN 60079-11

- 6.18 Monitoring of potential ignition sources according to DIN EN 50495 and DIN EN 13463- 6

- 6.19 Certificates

- 7 ATEX

- 7.1 Intended use

- 7.2 Identification markings according to ATEX directive 94/9/EC:

- 7.3 Meaning of the letter X in the type test certificate

- 7.4 Associated intrinsically safe electrical apparatus according to EN 60079-11

- 7.5 Safety device according to EN 50495

- 7.5.1 Temperature monitoring unit based on ignition protection "e" – increased safety according to EN 60079-7

- 7.5.1.1 Function of increased safety

- 7.5.1.2 Application in the 1-sensor variant

- 7.5.1.3 Application in the 2-sensor variant

- 7.5.1.4 Application of temperature transmitters

- 7.5.2 Minimum overpressure monitoring for static pressurized enclosure on the basis of ignition protection "p", pressurized enclosure according to EN 60079-2

- 7.5.2.1 Function of the static pressurized enclosure

- 7.5.2.2 Safety device for static pressurized enclosure

- 7.5.2.3 Application as safety device for static pressurized enclosure

- 7.6 Monitoring of potential ignition sources "b" according to EN 13463-6

- 8 Configuration level

- 9 Technical data

- 9.1 Analog inputs

- 9.2 Analog output

- 9.3 Binary input

- 9.4 Relay outputs

- 9.5 Measuring circuit monitoring

- 9.6 Voltage supply

- 9.7 Test voltages according to EN 60730, Part 1

- 9.8 Electrical safety

- 9.9 Environmental influences

- 9.10 Case

- 9.11 Approvals/approval marks

- 9.12 Important information for the probes in Chapter 9.13 to Chapter 9.15

- 9.13 Probes for the operating medium air

- 9.14 Probes for water and oil

- 9.15 Probes for air, water, and oil

- 10 Setup program

- 11 Alarm messages

- 12 Error messages

- 13 What to do, if ...

- 14 Information for devices with extra code 062 GL

- 15 Behavior of outputs

6 Safety Manual

47

2013-04-01

6.10 Determining the achieved Performance Level (PL)

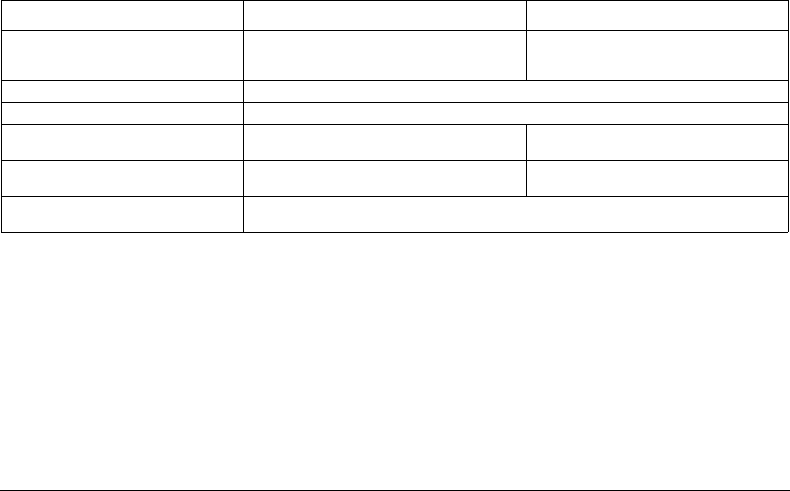

The following safety-related parameters are required to determine the Performance Level of components/devices:

As further parameters to be observed, operational aspects such as the demand rate and/or the test rate of the safety function

can also influence the resulting PL.

Excerpt from DIN EN ISO 13849-1:2008-12

Average failure probability of a safety

function on demand (overall system)

SIL2:

Low demand: PFD

avg

<10

-2

High demand: PFH < 10

-6

SIL3:

Low demand: PFD

avg

<10

-3

High demand: PFH < 10

-7

Interval for repeat test No repeat test

Planned operating duration 10 years

Architecture according to DIN EN ISO

13849-1

Sensor system, one-channel: Cat. 2 Sensor system, two-channel: Cat. 3

MTTF

d

-DC

avg

according to DIN EN

ISO 13849-1 Table K.1

PL d: ≥ 62 years DC

avg

≥ 60 % PL e: ≥ 62 years DC

avg

≥ 90 %

Mode of operation and software

class according to DIN EN 14597

The JUMO safetyM STB/STW Ex possesses the following modes of operation:

2B, 2D, 2F, 2K, 2J, 2V, 2N, 2P software class C

H

This excerpt contains references to the complete standard DIN EN ISO 13849-1:2008-12, which are therefore not

reproduced in this chapter.

Table 9:

Safety feature Requirement / comment