Manual

Table Of Contents

- Refrigerated and Heating Circulators, F12-MA...FPW50-MA

- Operating manual

- Intended use

- Operator responsibility – Safety recommendations

- Operating instructions

- Safety notes for the user

- Operating controls and functional elements

- Preparations

- Operating procedures

- Setting of temperatures

- Safety installations, warning functions

- Menu functions

- Troubleshooting guide / error messages

- Electrical connections

- Remote control

- JULABO Service – Online remote diagnosis

- Cleaning / repairing the unit

Preparations

30

5. Preparations

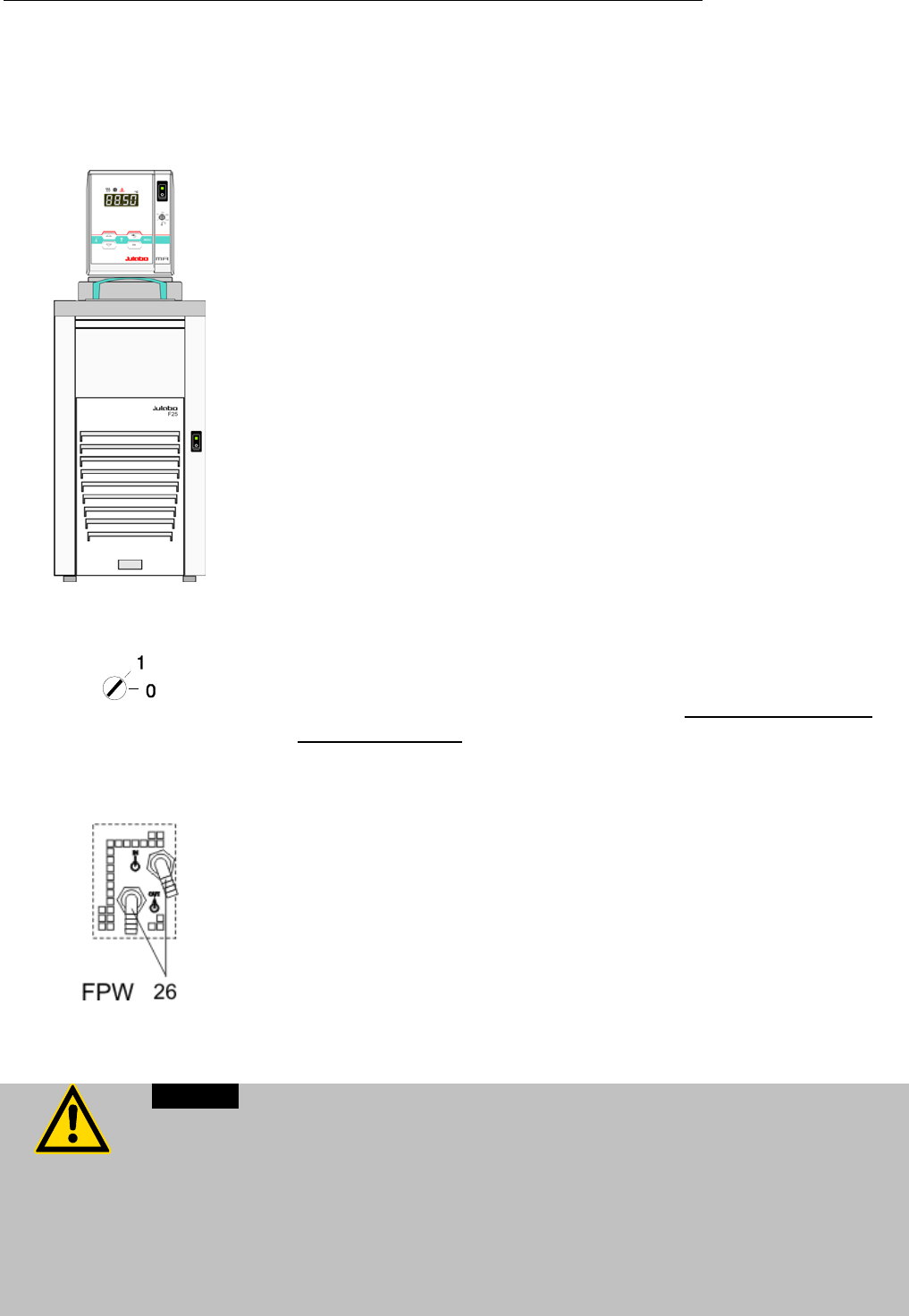

5.1. Installation

• Place the unit on an even surface on a pad made of non-

flammable material.

F34: The circulator fitted with a stainless steel bridge is placed

on on the back of the bath tank leaving the bath open on the

front side.

• The place of installation should be large enough and provide

sufficient air ventilation to ensure the room does not warm up

excessively because of the heat the instrument radiates to the

environment. (Max. permissible ambient temperature: 40 °C).

With regard to a disturbance in the cooling loop (leakage), the

guideline EN 378 prescribes a certain room space to be

available for each kg of refrigerant.

The necessary amount of refrigerant is specified on the type plate.

> For 0.25 kg of refrigerant R134a, a room space of 1 m

3

is required.

> For 0.52 kg of refrigerant R404A, a room space of 1 m

3

is required.

> For 0.49 kg of refrigerant R507, a room space of 1 m

3

is required.

• Set selector dial for cooling machine (19) in position "1" for

operation with MA circulator.

(only F25, F34)

•

Keep at least 20 cm of open space on the front and rear venting

grids.

• Do not set up the unit in the immediate vicinity of heat sources

and do not expose to sun light

• Before operating the unit after transport, wait about one hour

after setting it up. This will allow any oil that has accumulated

laterally during transport to flow back down thus ensuring

maximum cooling performance of the compressor.

Only water cooled models:

Ensure circulation of cooling water by connecting the tubing to

cooling water inlet and outlet on the rear of the refrigerated

circulator.

• Cooling water connecter G¾"

• Cooling water see page 22

5.2. Bath fluids

Caution:

Carefully read the safety data sheet of the bath fluid used, particularly with

regard to the fire point!

If a bath fluid with a fire point of ≤65 °C is used, only supervised operation is

possible.

Water: The quality of water depends on local conditions.

• Due to the high concentration of lime, hard water is not suitable for

temperature control because it leads to calcification in the bath.

•

Ferrous water can cause corrosion - even on stainless steel.