Use and Care Manual

4

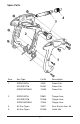

How to make A Wire Wrapped Connection:

Step 1:

Select the Proper Bit and

Sleeve for the Wire Being used

Step 2:

Insert the wire into the

Wire Slot

Step 3:

Anchor the Wire

Step 4:

Insert the terminal

Step 5:

Finished connection

Some Hints on Making Wrapped Connections

Do not press too hard. Let the OK tools

do the work. Excessive pressure can

lead to overwrapping. Backforce “BF”

to prevent overwrapping is available on

most power tools and is recommended

for use with 26 through 30 AWG wire.

Just keep the OK tool on the terminal

until the wrap is complete. Early

removal can result in spiral and open

wraps.

Feed Wire Correctly!

It’s easy to feed wire into the slot in

the OK bit correctly. Be sure the

stripped end of the wire is “pushed-in”

all the way.

Use the Correct Bit and

Sleeve!

Wire wrapping is a precision technique

and the wrong bit and sleeve just can-

not do the job. Improper selection can

cause problems ranging from “Pigtails”

to loose wraps.

Easy Does It! Stay With It!

Insufcient

Turns

Overwrap

Open

Wrap

Spiral

Wrap

Pigtail