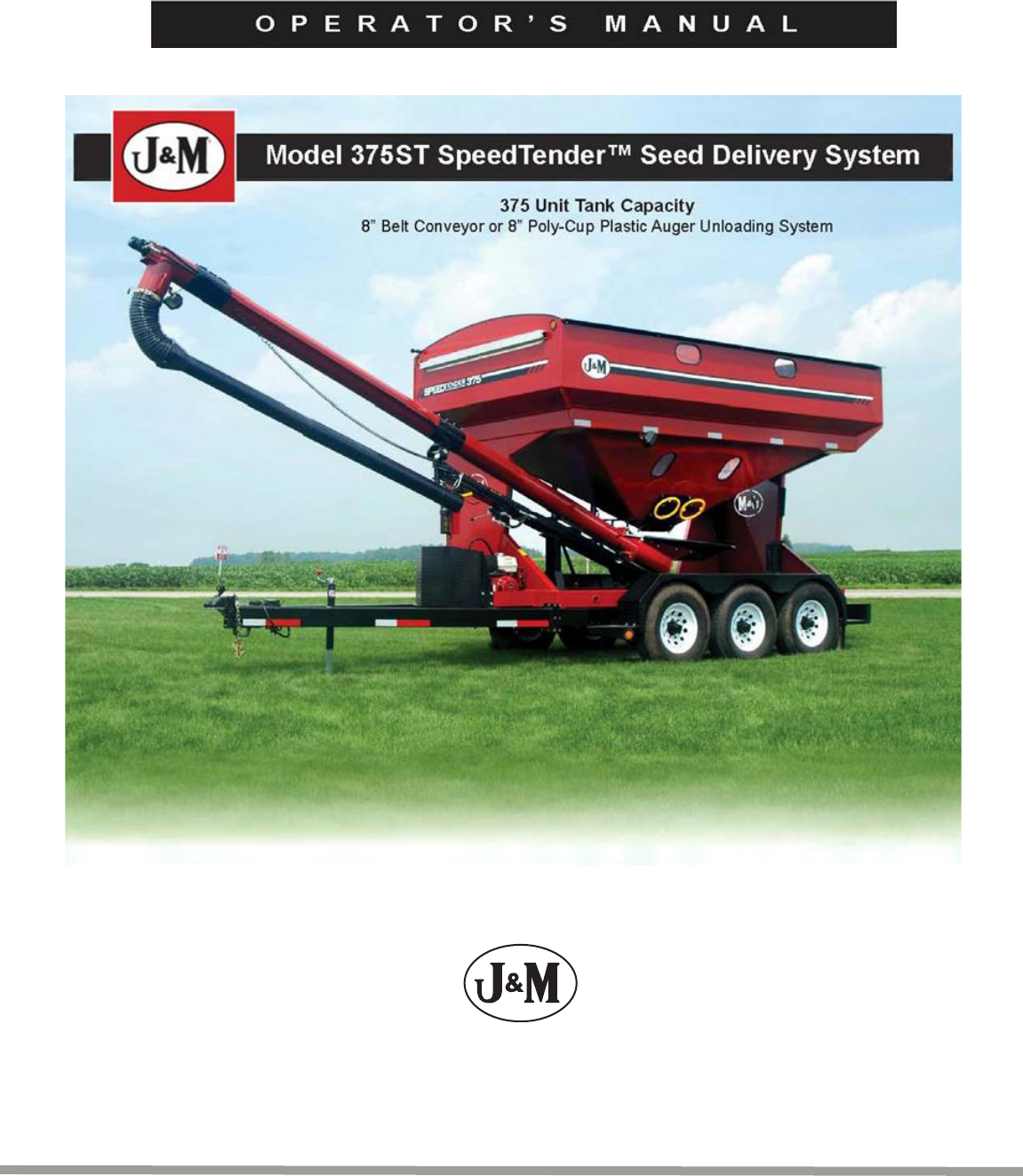

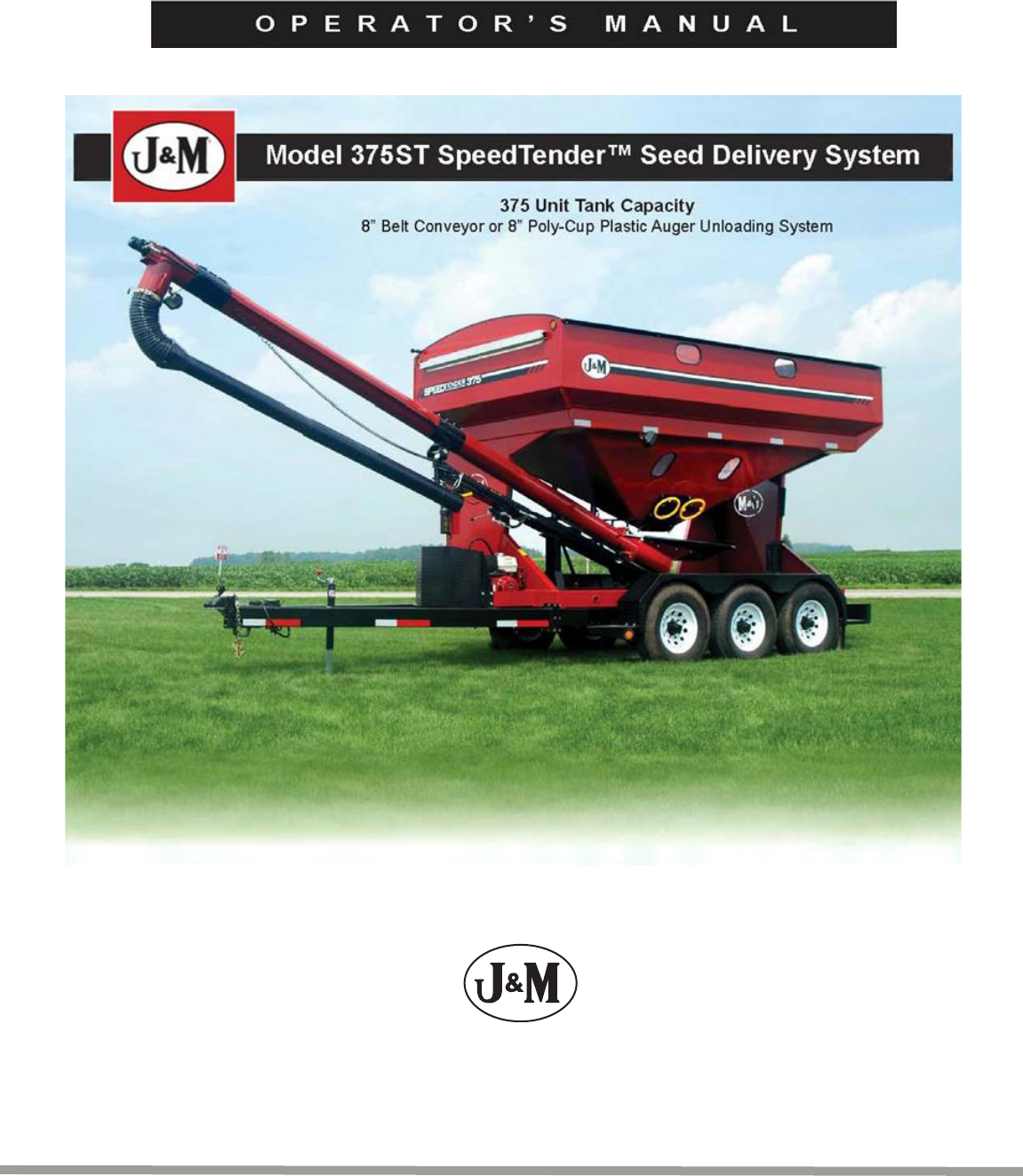

J. & M. Mfg. Co., Inc. P.O. Box 547 Fort Recovery, OH 45846 Ph: (419) 375-2376 Fax: (419) 375-2708 www.jm-inc.com (Rev.

Table of Contents GENERAL INFORMATION 1 To the dealer......................................................................................................................................................1 1 Express warranty...............................................................................................................................................1 2 Service .....................................................................................................................................

Table of Contents 23 2.11 Daily service (5-10 hours of use) ............................................................................................................23 23 2.12 End of the year service.............................................................................................................................23 24 2.13 Removing from storage............................................................................................................................24 25 2.14 Troubleshooting .

General Information TO THE DEALER: Read manual instructions and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the Operator’s Manual are completed before releasing equipment to the owner. The dealer must complete the Warranty Registration Card attached to the front inside cover of this manual and return to J. & M. Mfg. Co., Inc. at the address indicated on the card.

General Information The manufacturer reserves the right to make product design and material changes at any time without notice. They shall not incur any obligation or liability to incorporate such changes and improvements in products previously sold to any customer, nor shall they be obligated or liable for the replacement of previously sold products with products or parts incorporating such changes.

General Information TO THE OWNER: The purpose of this manual is to assist you in operating and maintaining your Speed Tender in a safe manner. Read it carefully. It furnishes information and instructions that will help you achieve years of dependable performance and help maintain safe operating conditions. If this machine is used by an employee or is loaned or rented, make certain that the operator(s), prior to operating: 1. Is instructed in safe and proper use. 2.

General Information 1. Understand that your safety and the safety of other persons are measured by how you service and operate this ma chine. Know the positions and functions of all controls before you try to operate them. Make sure to check all controls in a safe area before starting your work. 2. The safety information given in this manual does not replace safety codes, federal, state, or local laws. Make certain your machine has the proper equipment as designated by local laws and regulations. 3.

1.0 Operations 1.1 Preparing the Towing Vehicle Before towing the Speed Tender, refer to towing vehicle’s owner’s manual for information concerning hitch capacities, hitch adjustments, and tire inflation. Towing vehicle must be equipped with proper electric braking components. NOTE: The Speed Tender is equipped with LED lights. The towing vehicle may require a flasher upgrade for lights to operate properly.

1.0 Operations Figure 1.1 1.4 Transporting NOTE: Make sure the jack is in the horizontal position before transporting. NOTE: Check to make sure the boom arm is in the boom rest and the lynch pin is in place with the conveyor/auger ratchet strap securely fastened. NOTE: Make sure that the collapsible hopper is in the up position. When transporting the Speed Tender on public roads, it is recommended to have the boom in the forward facing position.

1.0 Operations WARNING: Purge hydraulic system of air before operating Speed Tender to prevent serious injury or death. WARNING: Wear proper hand and eye protection when searching for leaks. Use wood or cardboard instead of hands. 1. 2. 3. 4. 5. 6. Check to make sure all fittings and hardware are in proper operating condition. Replace if worn or broken. Check engine fluid levels and sight gauge on reservoir for proper operating levels.

1.0 Operations 1.6 Field Operation WARNING: The Speed Tender must be hooked to the towing vehicle during loading and unloading. 1. Position the Speed Tender next to the planter/drill so the conveyor/auger will reach the planter box. 2. Remove lynch pin from Boom Arm. (Figure 1.3). 3. Start the hydraulic power unit and increase throttle speed. (Allow hydraulic fluid to warm-up.) (Figure 1.2). 4. Raise the boom out of the Boom Rest using the handheld control (Figure 1.4).

1.0 Operations Wireless Remote Manual Hand Wheels Handheld Control Figure 1.4 See Section 4.1 for Remote Options Figure 1.5 Hopper Up Figure 1.6 8. Open door on Speed Tender with manual hand wheel (Figure 1.5). NOTE: The deluxe option handheld control and wireless remote operates the opening and closing of hydraulic doors (Figure 1.4). WARNING: Empty-out the rear compartment first to help prevent the chance of flipping the Speed Tender. 9. 10. 11. 12.

1.0 Operations 13. 14. 15. 16. 17. 18. 19. 20. Position boom above boom rest and lower to allow its full weight on the boom rest. Replace lynch pin in Boom Arm. Move the boom locking handle to lock position. Make sure that the conveyor/auger hold down ratchet strap is tight enough that the conveyor auger will not move during transportation. Make sure the collapsible hopper is in the up position for storage (Figure 1.6).

1.0 Operations 11. 12. 13. 14. Lock collapsible hopper in the up position (Figure 1.6). Position the wagon or bulk seed container over the collapsible hopper. Use the handheld controller or wireless remote to start the conveyor/auger. Fill the Speed Tender to desired level. WARNING: Fill the front compartment first to help prevent the chance of flipping. 15. 16. 17. 18. 19. 20. Run the conveyor/auger until the collapsible hopper is empty.

1.0 Operations 7. 8. 9. 10. 11. 12. Undo the conveyor/auger hold down ratchet strap (Figure 1.3). Swing the collapsible hopper end out from under the Speed Tender shell. Move the boom lock handle to the “Lock” position. Place the collapsible hopper in the up position (Figure 1.6) With the discharge end lower than the collapsible hopper end, place the discharge end into a 5 Gal. bucket (Figure 1.9). Using the hand held controller, start the conveyor/auger and run until completely empty.

1.0 Operations 1.9 Adjusting the Tarp Tension in Hanger Bracket 1. 2. 3. 4. 5. 6. Fully unroll the tarp as shown in Figure 1.11. Remove the two bolts that hold the tarp U-Joint on the splined shaft. Remove the u-joint from the spline shaft. Rotate u-joint and handle three or four spline teeth. NOTE: Clockwise to tighten the tarp or counter-clockwise to loosen it. Slide the u-joint and handle back onto the spline shaft. Replace and tighten the two bolts. U-Joint Bolts Figure 1.11 1.

2.0 Service 2.1 Grease Conveyer/Auger Bearings Grease the conveyor/auger bearings every 10 hours of operation and before storage. Use only two pumps of grease per bearing (Figure 2.1). NOTE: Over lubrication of these bearings will result in premature failure. NOTE: The conveyor has four bearings that need grease (two at each end). The auger is equipped with one bearing (at hopper end). Grease Point Figure 2.1 2.2 Grease Boom Arm Grease pivot points on boom arm every 50 hours and before storage (Figure 2.

2.0 Service 2.3 Tire Pressure The following is to be used as a general guide for tire inflation. Figures can vary depending on specific brand of tire used. It is important that tires are inspected before and after unit is loaded. Start with the minimum pressure indicated. The tire should stand up with no side wall buckling or distress as tire rolls. Do not exceed maximum recommended tire pressure. 80 psi is the cold rating on the tire that is standard for the Speed Tender.

2.0 Service 2.5 Wheel Bearings The wheel bearings need to be cleaned, inspected, and repacked every 12 months or 12,000 miles. Use a number 2 wheel bearing grease to repack the bearings. Bearing Inspection and Service: 1. Jack up Speed Tender. 2. Remove wheel lug-nuts. 3. Remove wheel from hub. 4. Remove grease cap. NOTE: Be careful not to dent or cut a hole in grease cap. 5. Remove the cotter pin, nut, and washer. 6. Wiggle the hub to take the outer wheel bearing out. 7.

2.0 Service 2.6 Hydraulic Power Unit Daily (every 5 hours of use): 1. Check oil level. 2. Inspect for oil leaks and repair as necessary. 3. Check all hoses, fittings, bolts and hardware to make sure that they are secure and properly tightened. 4. Check motor oil level. See Engine operator’s manual for details on oil levels, oil types, and service intervals. Once per season (every 20-25 hours of use): Change hydraulic oil filter element with either a NAPA 155Z or a FRAM P1654A Filter.

2.0 Service Remove Remove Discharge Pan Bearing Mounting Plate Jam Nut Adjustment Bolt Figure 2.3 Loosen these bolts when adjusting belt tension. Typical each side. Conveyer Clean-out Door Figure 2.4 2.8 Adjusting Conveyer Belt Tracking 1. 2. Loosen (Do Not Remove) the 4 bolts on the two bearing mounting plates located at the collapsible hopper end of the conveyor (Figure 2.5). Operate the conveyor at a slow speed. CAUTION: Keep hands and clothing away from moving parts. 3. 4. 5. 6. 7.

2.0 Service 2.9 Belt Tensioning NOTE: You need to adjust your belt tension at least once a year. Remove the head pan and head pan gasket (Figure 2.3). Loosen (Do Not Remove) the 4 bolts on the two bearing mounting plates located at the discharge end of the conveyor (Figure 2.3). Loosen jam nut on adjustment bolt at discharge end (Figure 2.3). Torque threaded adjustment bolt to 23 ft-lb. Operate the conveyor at a slow speed. 1. 2. 3. 4. 5. CAUTION: Keep hands and clothing away from moving parts. 6. 7.

2.0 Service How to adjust electric brakes: 1. Park the Speed Tender on firm and level ground. 2. Block the trailer tires on the opposite side securely so that no forward or rearward movement is possible. 3. Jack up the Speed Tender. 4. Secure the trailer on jack stands of adequate capacity front and rear. 5. At the back of the wheel, on the brake backing plate, there is a small rubber plug near the bottom of the backing plate. Pry out this plug to give access to the star wheel adjuster. 6.

2.0 Service Replacing Brake Linings: 1. Remove the brake shoe retract spring. 2. Remove the shoe hold down assembly by holding the back of the pin with one hand and pushing against the spring and twisting with a hold down spring tool until the cup is released. 3. Remove both shoes together leaving the adjuster assembly and spring intact. 4. Clean the backing plate and lever arm. 5. Inspect magnet arm for any loose or worn parts. 6. Replace springs that are broken, bent, or weak. 7.

2.0 Service Straight Edge Abnormal Wear (Replace) Normal Wear Figure 2.7 Voltage in the system should begin at 0 volts. As the controller bar is slowly actuated, the voltage should gradually increases to about 12 volts. This is referred to as modulation. No modulation means that when the controller begins to apply voltage to brakes it applies an immediate high voltage, which causes the brakes to apply instantaneous maximum power.

2.0 Service Brake Drum Inspection: There are two areas of the brake drum that are subject to wear and require inspection. These two areas are the drum surface where the brake shoes make contact during stopping and the armature surface where the magnet contacts (only in electric brakes). The drum surface should be inspected for excessive wear or heavy scoring. If worn more than .020” oversized, or if the drum has worn out of round by more than .015”, then the drum surface should be turned.

2.0 Service 1. Grease the conveyor/auger bearings. Use only two pumps of grease per bearing. NOTE: Over lubrication of these bearings will result in premature failure. NOTE: The conveyor has four bearing that need greased (two at each end). The auger is equipped with two bearings (one at each end) (See section 2.1). 2. Grease pivot points on boom arm before storage. 3. The wheel bearings need to be cleaned, inspected, repacked, and adjusted. Use a number 2 wheel bearing grease to repack the bearings. 4.

2.0 Service 9. Check engine oil level. See Engine operator’s manual for details on oil levels, oil types, and service intervals. 10. Check Speed Tender lights before each time you tow. 11. Make sure that the conveyor/auger hopper guard is in place. 12. Reattach battery and check to make sure that it is fully charged. IMPORTANT: Be sure to disconnect the scales from the battery before charging. 2.14 Troubleshooting Problems Solutions Unit sways during travel a. Check tire pressure. b.

2.0 Service Problems Solutions Locking brakes a. Replace any weak or broken springs in brakes b. Replace any excessively worn or contaminated linings Grabbing brakes a. Replace any excessively worn or contaminated linings Surging brakes a. Trailer is not adequately grounded Belt is not moving - Hydraulic pump is not producing sufficient pressure or volume to belt motor. a. Check for pinched or leaking hydraulic line b. Allow hydraulic oil to warm up c. Increase engine R.P.M. d.

2.0 Service Problems Excessive wear to belt edge - Tracking is off. Solutions a. Adjust belt tension and tracking (See section 2.8). Excessive wear to belt edge - Rubber skirting is worn or out of place. a. Replace rubber skirting. b. Adjust rubber skirting. Boom arm will not move up or down - Engine R.P.M. slow. a. Increase engine R.P.M. Boom arm will not move up or down - Hydraulic pump is not producing sufficient pressure or volume to hydraulic cylinder. a. Check for pinched or leaking hydraulic lines.

2.0 Service 2.15 Bolt Torque Specifications Standard Dry Torque in Foot-Pounds Bolt Dia. Pitch (in.) (threads/ inch) 1/4 5/16 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1-1/8 1-1/4 1-3/8 1-1/2 1-5/8 1-3/4 1-7/8 2 20 18 16 14 13 12 11 10 9 8 7 7 6 6 5.5 5 5 4.5 SAE SAE SAE SAE SAE SAE Grade 0-1-2 Grade 3 Grade 5 Grade 6 Grade 7 Grade 8 74,000 psi 100,000 psi 120,000 psi 133,000 psi 133,000 psi 150,000 psi Low Carbon Med. Carbon Med. Carbon Med. Carbon Med. Carbon Med. Carbon Steel Steel Heat T. Steel Temp.

3.0 Hydraulics 3.1 Standard Models (Raise and lower boom only)-JM0010317 2 Spool Valve Body # 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Description 1/4” I.D. Hose; 1/4” male NPT rigid X #6 female JIC swivel; 12” OAL 1/4” I.D. Hose; 3/8” male NPT rigid X #6 female JIC swivel; 107” OAL 1/4” I.D. Hose; 3/8” male NPT rigid X 3/8” male NPT swivel; 99” OAL 1/2” I.D. Hose; 3/8” male NPT swivel X #8 female JIC swivel; 34” OAL 1/2” I.D. Hose; #8 female JIC swivel X #8 female JIC swivel; 326” OAL 1/2” I.

3.0 Hydraulics 3.2 Deluxe Models (Raise and lower boom and open and close doors)-JM0010315 4 Spool Valve Body # 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Description 1/4” I.D. Hose; 1/4” male NPT rigid X #6 female JIC swivel; 12” OAL 1/4” I.D. Hose; 1/4” male NPT rigid X #6 female JIC swivel; 192” OAL 1/4” I.D. Hose; 3/8” male NPT rigid X #6 female JIC swivel; 107” OAL 1/4” I.D. Hose; 3/8” male NPT rigid X 3/8” male NPT swivel; 99” OAL 1/2” I.D.

3.0 Hydraulics 3.3 Deluxe Models with Conveyer/Auger Swing-JM0010316 5 Spool Valve Body # Description Part # 1 1/4" I.D. Hose; 1/4" male NPT rigid X #6 female JIC swivel; 12" OAL JM0010282 Qty. 2 2 1/4" I.D. Hose; 1/4" male NPT rigid X #6 female JIC swivel; 192" OAL JM0010300 4 3 1/4" I.D. Hose; 3/8" male NPT rigid X #6 female JIC swivel; 107" OAL JM0010283 1 4 1/4" I.D. Hose; 3/8" male NPT rigid X 3/8" male NPT swivel; 99" OAL JM0010284 1 5 1/4" I.D.

4.0 Wiring 4.1 Hydraulic Wiring Wireless Reciever or Handheld Controller Connector Reference Figures 4.1-4.4 C D E F G H J K L M N Function Boom swing front (optional) Boom swing rear (optional) Boom Up Boom Down Rear door up (optional) Front door down (optional) Power Front door up (optional) Rear door down (optional) Pump In Conveyor Start P E N D A F M C L G B H J K Figure 4.

4.0 Wiring Controllers/Remotes Item # Description 1 Handheld Controller 1 Part # JM0010311 Qty. 1 2 Handheld Controller 2 JM0010312 1 3 4 Wireless Remote 1 w/ Reciever Wireless Remote 2 w/ Reciever JM0010313 1 1 JM0010314 JM0014984 Handheld Controller 1 (tandard) Starts/Stops Motor Raises/Lowers Conveyer Conveyer/Auger Start Up Conveyer/Auger E F J M N E J F Blue Yellow Red Green/Black Green 1 N M Down Stop Figure 4.

4.0 Wiring JM0014999 JM0015005 Wireless Reciever 2 Wireless Remote 2 (optional) Starts/Stops Motor Raises/Lowers Conveyer Opens/Closes Tank Doors Hydraulic Conveyer/Auger Swing Electronic Auto Scale Shutoff Ground To Toggle 4 Switch Same as Figure 4.1 To Scale Display/Interface Section 4.3 Auto Scale Shutoff Directions for Wireless Remote 2 1. Turn Scale Head, Wireless Remote and Wireless Toggle Switch on. -The main screen showing gross and tared weight will display 2.

4.0 Wiring 4.

4.

4.

5.0 Parts Section 5.11 Section 5.10 Sections 5.8/5.9 Sections 5.5/5.6 Section 5.7 Section 5.1 Section 5.2 Section 5.2 Section 5.3 Section 5.

5.0 Parts 5.1 Ladder Parts 6 6 5* 1 5 8 9* 7 7 4 6 10 2 7 8 3 5 5 6 Ladder Item # 1 2 3 4 5 6 7 8 9 10 *Typical Other Side Description Top Ladder (Long) Bottom Ladder (Short) Bottom Ladder Support Ladder Gas Spring (120lbs) 3/8-16 X 1.0 Grade 5 Zinc Serrated Flange Hex Bolt 3/8-16 Grade 5 Zinc Serrated Flange Hex Nut 5/16-18 Grade 5 Zinc Centerlock Hex Nut 5/16-18 X 1.

5.0 Parts 5.2 Scale Parts 7 2 Scale Display Box-Qty. 1 Item # 1 2 3 4 5 6 7 Description Weigh Scale Box Weldment Weigh Scale Box door Chrome T-Handle Non-Locking 3/8 USS Flat Washer 3/8-16 X 1 1/2 Grade 5 Zinc Hex Bolt 3/8-16 Grade 5 Zinc Centerlock Hex Nut Scale Display/Interface Part # JM0009961 JM0002944 JM0001911 JM0003061 JM0001659 JM0001512 JM0007293 5 Qty. 1 1 1 6 2 2 1 1 4 3 6 12 9 10 Item # 8 9 10 11 12 13 14 Weigh Bar Mount-Qty.

5.0 Parts 5.3 Chassis Parts 10 1 18 8 10 19 9 17* 22 9 9 23 15 24 3 16 5 5 21* 11 12* 7* 12* 8 2 12* 6 14* 13* 4* 11* 27* 30* 20* Chassis Item # Description Part # Qty. 1 A-Frame Weldment (parts in section 5.

5.0 Parts Chassis (Continued) Item # Description Part # 14 3/8-16 Grade 5 Zinc Centerlock Hex Nut JM0001512 4 15 5/8 USS Flat Washer JM0003073 24 16 5/8-11 X 2 1/4 Grade 5 Zinc Hex Bolt JM0001493 12 17 1/2-13 X 1 3/4 Grade 5 Zinc Hex Bolt JM0002101 12 18 1/2 USS Flat Washer JM0003082 12 19 1/2-13 Grade 5 Zinc Centerlock Hex Nut JM0001511 12 20 3/8-16 X 1.

5.0 Parts 5.5 Auger Parts 42 12 39 7 5 39 40 9 6 8 6 41 16 3 34 7 4 14 10 52 2 53 52 51 37* 36* 30* 35* 22 23* 18 27 29* 39* 24* 18 31* 48* 47* 50 32* 50* 33* 45* 35* 44* 21* 20 38* 16* 39* 13 33* 26* 17 43 25* 11 53 54 46 15 28 19 Auger Item # Description 1 Flighting Assembly 2 1.83 X 226.63 Galvanized Hex Tube 3 7" Dia. HDPE Polycup (Idler end Cap) 4 7" Dia. HDPE Polycup (Standard Flighting) 5 7" Dia. HDPE Polycup (Drive end Cap) 6 3/8-16 X 3.

5.0 Parts Auger (Continued) Item # 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 Description Lower Tube Weldment Cleanout Door Weldment Hydraulic Motor w/ Pinhole in Shaft (No Key) 3/8-16 X 1 1/2 Grade 5 Zinc Carriage Bolt Field Light ASM Support Stand Weldment 3/8 USS Flat Washer Hopper Safety Grate 3/8-16 X 1.0 Grade 5 Zinc Carriage Bolt M6-1 X 20 Grade 8.8 Hex Bolt Hopper Tarp Support Tube Rubber Pipe Caps 1.

5.0 Parts 5.

5.0 Parts Conveyor 38 12.5 Long Nylon Strip Brush-Discharge End JM0009999 1 39 12.75 Long Nylon Strip Brush-Hopper End JM0001917 2 40 Front Nylon Brush Rubber BackingHopper End JM0002791 1 1 41 Inner Rubber Skirt-Discharge End JM0002749 2 2 42 Inner Rubber Skirt Clamp-Discharge End JM0002752 2 43 Hopper Pivot Bar JM0002786 1 44 Rubber Pipe Cap 1.

5.0 Parts 5.

5.0 Parts Boom Arm Item # 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 Description 3/8-16 X 1.5 Grade 5 Zinc Hex Bolt 3/8 USS Flat Washer 3/8-16 Grade 5 Zinc Serrated Flange Hex Nut 1.0-8 X 9.0 Grade 8 Zinc Hex Bolt 3/8-16 X 1.0 Grade 8 Zinc Serrated Flange Hex Bolt 3/8-16 Grade 5 Zinc Centerlock Hex Nut 1.0-8 X 5.0 Grade 8 Plain Hex Bolt 1 X 3.4 Clevis Pin w/ Cotter Pins 1/2-13 Grade 5 Zinc Hex Nut 1/2-13 Acorn Nut 3/4 USS Flat Washer 1 1/4-12 Grade 5 Plain Hex Jam Nut 1/8 NPT Grease Zerk (See Figure 2.

5.0 Parts 5.

5.0 Parts Manual Door Item # 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Description Manual Door Frame Weldment Manual Door Weldment 1/2 Dia. X 1/2 Long Shoulder Bolt Rubber Chute (Not Shown) 3/8-16 X 3/4 Grade 5 Zinc Carriage Bolt 3/8-16 Grade 5 Zinc Centerlock Hex Nut 3/8-16 X 3/4 Grade 5 Zinc Serrated Flange Hex Bolt 3/8-16 X 1.0 Grade 5 Zinc Hex Bolt 3/8-16 Grade 5 Zinc Hex Nut 1/2 USS Flat Washer 3/8 USS Flat Washer 3/8-16 X 1 3/4 Grade 5 Zinc Hex Bolt 3/8-16 X 1.

5.0 Parts 5.

5.0 Parts Shell Item # 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 29 Description Tank and Legs Weldment Hydraulic Power Unit Oval Window Grommet Oval Window 5/16-18 X 3 1/4 Grade 2 Countersunk Socket Torx Bolt 2 1/8 ID X 2 1/2 OD Grommet Field Light Assembly 1 ID X 1 3/8 OD Rubber Grommet Hydraulic Power Unit Panel 12.0 X 2.

5.0 Parts 5.13 Roll Tarp Parts *19 *24 5 14 Only Front Spring Return on Electric Tarp Option 11* 16* 17* 15 13* 17* 16* 25* 12* 9* 22* 23* 17 1 7 4 26 27 10 28 29 20 6 18 19 3 2 16 21 *Typical Other Side 16 8 17 Roll Tarp Item # Description Part # 1 Spring Return (Detail Section 5.13) JM0002437 Qty.

5.0 Parts 5.14 Spring Return Parts 2 6 2 3 8 3 7 4 5 5 11 1 5 12 Spring Return 10 Item # 3 9 Description Part # 1 1/4-20 X 1.0 Grade 5 Zinc Hex Bolt JM0002095 Qty. 2 2 1/4-20 X 1 1/2 Grade 5 Zinc Hex Bolt JM0002447 1 3 Roller Small JM0002439 5 4 Aluminum Spacer Rectangle JM0013484 2 5 1/4-20 Grade 5 Zinc Centerlock Nut JM0001505 5 6 Rectangular Plastic Spacer JM0002443 2 7 Short Plastic Spacer JM0002442 1 8 Spring Return Spring JM0000207 1 9 3/8-16 X 3.

5.0 Parts 5.16 Available Options Item # Description Product # 1 Gooseneck Frame and Hitch Assembly in place of standard A-Frame 375ST-GNO 2 5th Wheel Hitch on Gooseneck Frame Assembly in place of standard Truck Hitch. Includes 7-way Flat to 7-Way Round Adapter 375ST-5WH 3 Trailer Mount Kit in place of Standard Chassis (Deluxe All-Function Wireless Remote Control Option Recommended) 375ST-TM See Section 4.

5.0 Parts 6 8 Includes 8” Dia.

6.0 Aftermarket Installation Instructions 6.1 Scales Installation Note: For Scale parts see Section 5.3 1. 2. Slide the weigh bar into the scale mount. Making sure that the Weigh bar sticker is facing up (Figure 6.1). Insert two 3/8”-16 X 3 1/2” Grade 5 Zinc Hex Bolt (#1) into scale mount and tighten using 3/8”-16 Centerlock Hex Nut (#2) (Figure 6.1). 1 Figure 6.1 3. 2 4. Insert 4 Spacer Blocks in between the Shell/Leg Weldment and the Chassis Frame.

6.0 Aftermarket Installation Instructions 10. 11. 12. 13. 14. 15. 16. Remove Spacer Blocks (Figure 6.2) Remove the four 1 3/8” grommets located in the four chassis holes (Figure 6.4) Slide one grommet on to each of the weigh bar wires of B,C, and D. (Figure 6.4) NOTE: Spray grommets with a lubricant spray for ease of installation. Route each wire from B,C and D so they exit chassis hole (#6) (Figure 6.4). Slide the grommet from chassis hole (#6) over the wires from B, C, and D. (Figure 6.4).

6.0 Aftermarket Installation Instructions Back Plate Print Power Cord Plugin Plugin (Optional) Figure 6.7 Figure 6.