Product Manual

Liquid

Level

Liquid

Level

Liquid

Level

Plastic Siphon Pump Manual

Description

Just give it 5 strokes and it starts siphoning at 7gpm. Fits 15-30- and 55 gallon drums comes

with a 2" bung adapter. Ideal for pumping ammonium, compatible chemicals, detergents,

light acids, oil, rinse additives, and soda.

Specifications

Flow Rate . . . . . . . . . . . . . . . 8 oz/stroke, siphons at 7 GPM

Bung Adapter . . . . . . . . . . . . . . 2" BUNG

Discharge Hose Length . . . . . . . 4'

Wetted Parts . . . . . . . . . . . . . . PVC, Glass, NBR & Viton

Maximum Viscosity . . . . . . . . . 3000 SSU

Maximum Fluid Temperature . . . 140F/60℃

Assembly and Installation

1. Contact your chemical or fluid supplier to check for compatibility with pump prior to

installation and operation.

2. Remove the bung adapter and install on pump body with threaded end pointing down.

3. Insert pump assembly into 2”opening of 55 gallon drum and screw adapter clockwise into

drum.

4. Assemble discharge tube to pump discharge hose barb with worm gear clamp.

5. Test pump to verify that there are no leaks around the clamp.

6. Adjust pump to the height desired, and then tighten thumb screw in adapter until hand

tight.

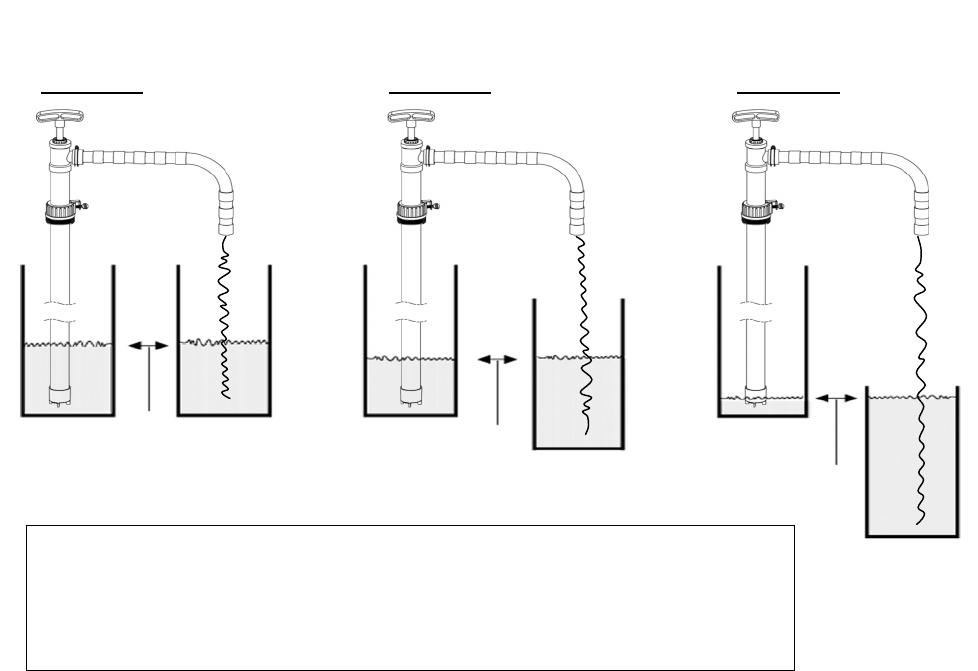

SIPHON ACTION ILLUSTRATIONS

NOTE: Receiving container must be physically lower than supply container for proper siphon

action to occur.

Example A

Receiving

Container

Container

Example C

Supply

Container

Example B

Supply

Container

Supply

Container

Receiving

Container

Container

Example

A

-

Siphon

action

will

stop

when

level

inboth

containers are

equal.

Example

B

-

Siphon

action

will

stop

when

liquid

level

heightin

receiving

container

is

physically

equal

to

liquidheight

of

supply

container.

Example

C

-

Siphon

action

will

stop

when

supply

container

level

has

reached

thebottom

Receiving

Container

Container