Flat Roof Attachment Install Manual

Installation

© 201

9 IronRidge, Inc. All rights reserved. Visit www.ironridge.com or call 1-800-227-9523 for more information.

FRA-01-MAN REV 1.1

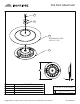

For freeze/thaw locations, a roof manufacturer's

approved sealant should be applied around the 3/8”

bolt and in the bracket’s slot prior to tightening the

bolt.

3

4

Tools Required: tape measure, chalk, approved sealing materials, roof screws, driver with 9/16” hex socket

Mark locations for Flat Roof Attachment. Roof

screws can be installed before or after racking is

installed. Type, size, and quantity of roof screws

to be specified by Structural Engineer. Fastener

size not to exceed #15. Screws should be

installed symmetrically to each other.

Attach rail mounting bracket with washers and 3/8”

hardware torqued to 250 in-lbs (21 ft-lbs). Seal

attachment and/or membrane per roofing

manufacturer’s requirements.

2

If using a membrane flashing, remove the silicone

washer's protective liner prior to attaching the

membrane. Thread a bolt into the base to help center

the membrane during the welding or adhering

process. Ensure membrane flashing is compatible with

existing roofing material.

1

Structural Certification

Designed and Certified for Compliance with the International Building Code & ASCE/SEI-7.

UL 2703

Conforms to UL 2703 (2015) Mechanical and Bonding requirements. See Ironridge Tilt or

Flush Mount Manuals for full ratings.

LA Research Reports (LARR)

Approved for use in City of Los Angeles per LARR #26185

Backfill rail mounting

bracket's slot with

approved sealant.