Guidelines

Thermal Mechanical Design

32 Dual-Core Intel

®

Xeon

®

Processor 7000 Sequence Thermal /Mechanical Guidelines

2.4.7 Components Overview

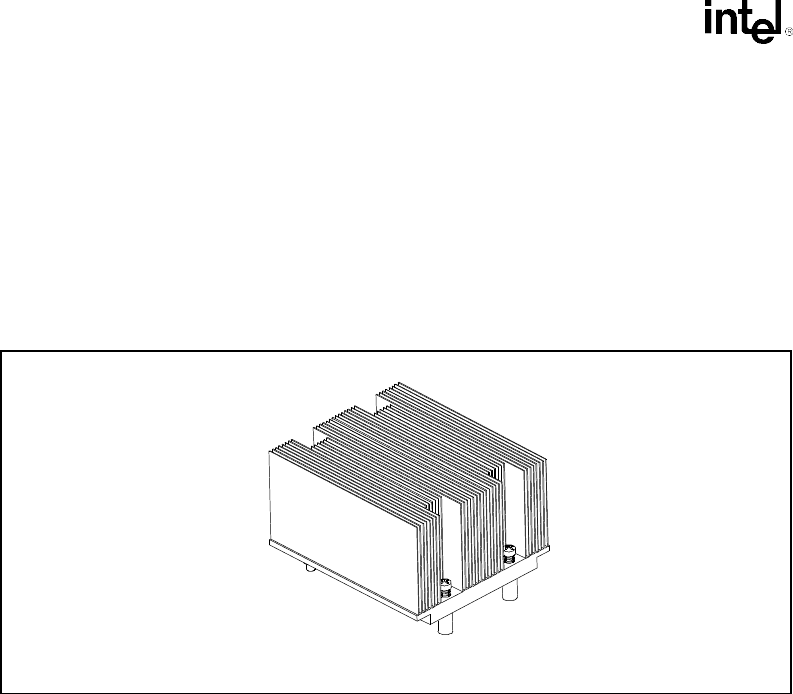

2.4.7.1 Heatsink with Captive Screws and Standoffs

The CEK reference heatsink uses snapped-fin technology for its design. It consists of a copper base

and copper fins with Shin-Etsu G751 thermal grease as the TIM. The mounting screws and

standoffs are also made captive to the heatsink base for ease of handling and assembly as shown in

Figure 2-13.

NOTE: Refer to Appendix A for more detailed mechanical drawings of the heatsink.

The function of the standoffs is to provide a bridge between the chassis and the heatsink for

attaching and load carrying. When assembled, the heatsink is rigid against the top of the standoff,

and the standoff is rigid to a chassis standoff with the CEK spring firmly sandwiched between the

two. In dynamic loading situations the standoff carries much of the heatsink load, especially in

lateral conditions, when compared to the amount of load transmitted to the processor package. As

such, it is comprised of steel. The distance from the bottom of the heatsink to the bottom of the

standoff is 10.26 mm [0.404 in.] for a board thickness of 1.57 mm [0.062 in]. The standoff will

need to be modified for use in applications with a different board thickness, as defined in

Section 2.4.4.2.

The function of the screw is to provide a rigid attach method to sandwich the entire CEK assembly

together, activating the CEK Spring under the baseboard, and thus providing the TIM preload. A

screw is an inexpensive, low profile solution that does not negatively impact the thermal

performance of the heatsink due to air blockage. Any fastener (i.e. head configuration) can be used

as long as it is a panel screw (not fully threaded), of steel construction, the head does not interfere

with the heatsink fins, and is of a length to ensure that the screw head bottoms out on the heatsink

base before the screw shaft bottoms out in the chassis standoff. This is due to varying

configurations of chassis standoff heights.

Although the CEK heatsink fits into the legacy volumetric keep-in, it has a larger footprint due to

the elimination of retention mechanism and clips used in the older enabled thermal/mechanical

components. This allows the heatsink to grow its base and fin dimensions, further improving the

thermal performance. A drawback of this enlarged size and use of copper for both the base and fins

is the increased weight of the heatsink. The CEK heatsink is estimated to weigh twice as much as

previous heatsinks used with Intel Xeon processors. However, the retention scheme employed by

CEK is designed to support heavy heatsinks (approximately up to 1000 grams) in cases of shock,

vibration and installation as explained in Appendix C.

Figure 2-13. Isometric View of the 2U+ CEK Heatsink