Guidelines

Dual-Core Intel

®

Xeon

®

Processor 7000 Sequence Thermal /Mechanical Guidelines 33

Thermal Mechanical Design

2.4.7.2 Thermal Interface Material (TIM)

A TIM must be applied between the package and the heatsink to ensure thermal conduction. The

CEK reference design uses Shin-Etsu G751 thermal grease.

The recommended grease dispenses weight to ensure full coverage of the processor IHS is given

below. For an alternate TIM, full coverage of the entire processor IHS is recommended.

The following guidelines apply to Shin-Etsu G751 thermal grease. The use of a semi-automatic

dispensing system is recommended for high volume assembly to ensure an accurate amount of

grease is dispensed on top of the IHS prior to assembly of the heatsink. A typical dispense system

consists of an air pressure and timing controller, a hand held output dispenser, and an actuation foot

switch. Thermal grease in cartridge form is required for dispense system compatibility. A precision

scale with an accuracy of ±5 mg is recommended to measure the correct dispense weight and set

the corresponding air pressure and duration. The IHS surface should be free of foreign materials

prior to grease dispense.

Additional recommendations include recalibrating the dispense controller settings after any two

hour pause in grease dispense. The grease should be dispensed just prior to heatsink assembly to

prevent any degradation in material performance. Finally, the thermal grease should be verified to

be within its recommended shelf life before use.

The CEK reference solution is designed to apply a compressive load of up to 222 N [50 lbf] on the

TIM to improve the thermal performance.

Note: Please refer to the manufacturer’s guidelines for specific specifications and handling instructions

for the thermal interface material.

2.4.7.3 CEK Spring

The CEK spring, which is attached on the secondary side of the baseboard, is made from 0.80 mm

[0.0315 in.] thick 301 stainless steel half hard. Any future versions of the spring will be made from

a similar material. The CEK spring has four embosses (called “hats”) which, when assembled, rest

on the top of the chassis standoffs. The CEK spring is located between the chassis standoffs and the

heatsink standoffs. The purpose of the CEK spring is to provide compressive preload at the TIM

interface when the baseboard is pushed down upon it. This spring does not function as a clip of any

kind. The two tabs on the spring are used to provide the necessary compressive preload for the TIM

when the whole solution is assembled. The tabs make contact on the secondary side of the

baseboard. In order to avoid damage to the contact locations on the baseboard, the tabs are

insulated with a 0.127 mm [0.005 in.] thick Kapton* tape (or equivalent). Figure 2-14 shows an

isometric view of the CEK spring design.

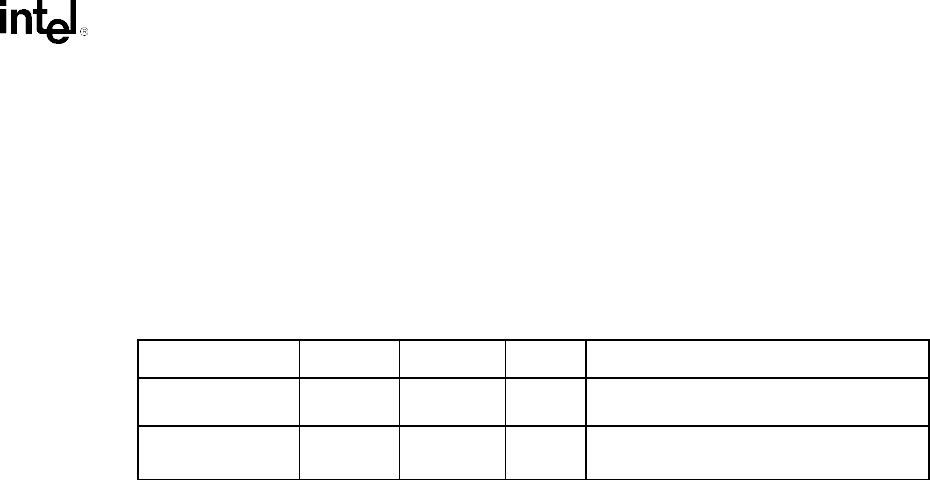

Table 2-5. Recommended Thermal Grease Dispense Weight

Dual-Core Intel® Xeon® Processor 7000 Sequence

Parameter Minimum Maximum Unit Notes

TIM Dispense

Weight

600 mg Shin-Etsu G751. Dispense weight is an

approximate target.

TIM loading

provided by CEK

33

147

50

222

lbf

N

Generated by the CEK.