User manual

7

RF1V Force Guided Relays / SF1V Relay Sockets

Instructions

1. Driving Circuit for Relays

1. To make sure of correct relay operation, apply

rated voltage to the relay coil. Pickup and drop-

out voltages may differ according to operating

temperature and conditions.

2. Input voltage for DC coil:

A complete DC voltage is best for the coil power

to make sure of stable operation. When using a

power supply containing a ripple voltage, sup-

press the ripple factor within 5%. When power

issuppliedthrougharecticationscircuit,relay

operating characteristics, such as pickup volt-

age and dropout voltage, depend on the ripple

factor. Connect a smoothing capacitor for better

operating characteristics as shown below.

+

–

R

Smoothing

Capacitor

Relay

Pulsation

Emin Emax Emean

DC

Ripple Factor (%) × 100%

Emax –

Emin

Emax= Maximum of pulsating current

Emin= Minimum of pulsating current

Emean = DC mean value

Emean

3. Operating the relay in sync with an AC load:

If the relay operates in sync with AC power volt-

age of the load, the relay life may be reduced. If

this is the case, select a relay in consideration of

the required reliability for the load. Or, make the

relay turn on and off irrespective of the AC power

phase or near the point where the AC phase

crosses zero voltage.

R

Vin

EAC

TE

Load

V

in

E

AC

4. Leakage current while relay is off:

When driving an element at the same time as

the relay operation, special consideration is

needed for the circuit design. As shown in the

incorrect circuit below, leakage current (Io)

owsthroughtherelaycoilwhiletherelayisoff.

Leakage current causes coil release failure or

adversely affects the vibration resistance and

shock resistance. Design a circuit as shown in

the correct example.

Incorrect

R

TE

lo

Correct

R

5. Surge suppression for transistor driving circuits:

When the relay coil is turned off, a high-voltage

pulse is generated. Be sure to connect a diode

to suppress the counter electromotive force.

Then, the coil release time becomes slightly

longer. To shorten the coil release time, connect

a Zener diode between the collector and emitter

of the controlling transistor. Select a Zener diode

with a Zener voltage slightly higher than the

power voltage.

R

Counter emf

suppressing diode

Relay

+

–

6. The coil terminal of the relay has polarity.

Connect terminals according to the internal

connection diagram. Incorrect wiring may cause

malfunction.

2. Protection for Relay Contacts

1. The contact ratings show maximum values.

Make sure that these values are not exceeded.

Whenaninrushcurrentowsthroughtheload,

the contact may become welded. If this is the

case, connect a contact protection circuit, such

as a current limiting resistor.

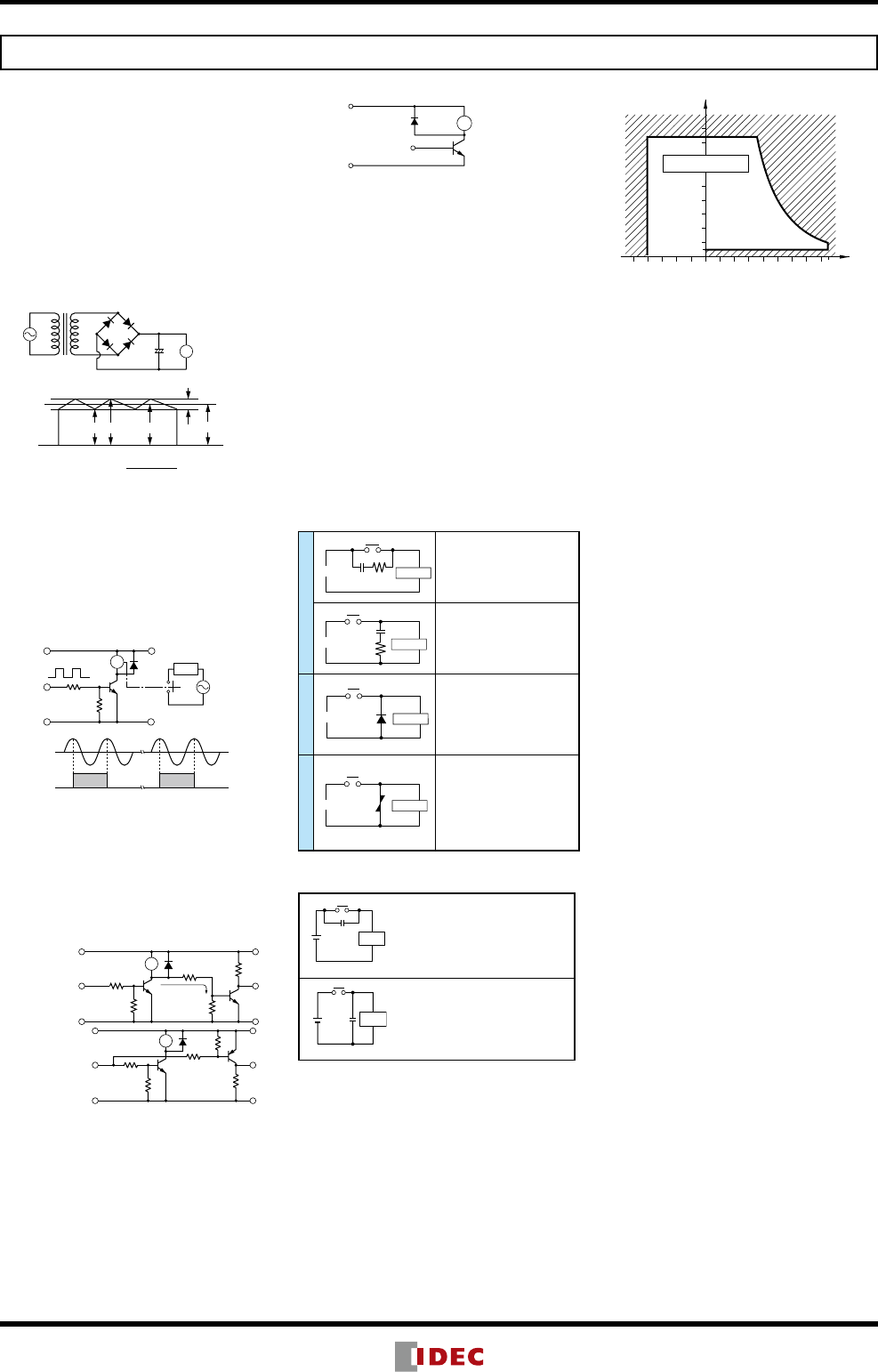

2. Contact protection circuit:

When switching an inductive load, arcing causes

carbides to form on the contacts, resulting in an

increased contact resistance. In consideration

of contact reliability, contact life, and noise

suppression, use of a surge absorbing circuit

is recommended. Note that the release time

of the load becomes slightly longer. Check the

operation using an actual load. Incorrect use of

a contact protection circuit will adversely affect

switching characteristics. Four typical examples

of contact protection circuits are shown in the

following table:

RC

Power

CR

Ind. Load

This protection circuit can be

used when the load impedance is

smaller than the RC impedance in

an AC load power circuit.

R: Resistor of approximately the

same resistance value as the load

C:0.1to1μF

C

R

Power

Ind. Load

This protection circuit can be used

for both AC and DC load power

circuits.

R: Resistor of approximately the

same resistance value as the load

C:0.1to1μF

Diode

+

–

D

Power

Ind. Load

This protection circuit can be used

for DC load power circuits. Use a

diode with the following ratings.

Reverse withstand voltage:

Power voltage of the load circuit

× 10

Forward current:

More than the load current

Varistor

Varistor

Power

Ind. Load

This protection circuit can be used

for both AC and DC load power

circuits.

For a best result, when using on a

power voltage of 24 to 48V AC/DC,

connect a varistor across the load.

When using on a power voltage

of 100 to 240V AC/DC, connect a

varistor across the contacts.

3. Do not use a contact protection circuit as shown

below:

Power

C

Load

This protection circuit is very effective in arc

suppression when opening the contacts. But,

the capacitor is charged while the contacts

are opened. When the contacts are closed,

the capacitor is discharged through the

contacts, increasing the possibility of contact

welding.

C

Load

Power

This protection circuit is very effective in arc

suppression when opening the contacts.

But, when the contacts are closed, a current

owstochargethecapacitor,causingcontact

welding.

Generally,switchingaDCinductiveloadismoredifcult

than switching a DC resistive load. Using an appropriate

arc suppressor will improve the switching characteristics of

a DC inductive load.

3. Usage, transport, and storage conditions

1. Temperature, humidity, atmospheric pressure

during usage, transport, and storage.

➀ Temperature: –45°C to +85°C (no freezing)

When the temperature is 70 to 80°C, reduce

the 6A max. switching current by 0.1 A/°C

➁ Humidity: 5 to 85%RH (no condensation)

The humidity range varies with temperature.

Use within the range indicated in the chart

below.

➂ Atmospheric pressure: 86 to 106 kPa

Operating temperature and humidity range

Tolerance Range

(Avoid freezing

when using at

temperatures

below 0ºC)

(Avoid

condensation

when using at

temperatures

above 0ºC)

85

5

0–40

85

Humidity (%RH)

Temperature (ºC)

2. Condensation

Condensation occurs when there is a sudden

change in temperature under high temperature

and high humidity conditions. The relay insula-

tion may deteriorate due to condensation.

3. Freezing

Condensation or other moisture may freeze on

the relay when the temperatures is lower than

0ºC. This causes problems such as sticking of

movable parts or delay in operation.

4. Low temperature, low humidity environments

Plastic parts may become brittle when used in

low temperature and low humidity environments.

4. Panel Mounting

When mounting DIN rail mount sockets on a panel,

take the following into consideration.

Use M3.5 screws, spring washers, and hex nuts.•

For mounting hole layout, see page 6.•

Keep the tightening torque within 0.49 to 0.68 •

N

·

m. Excessive tightening may cause damage to

the socket.

5. Others

1. General notice:

➀ To maintain the initial characteristics, do not

drop or shock the relay.

➁ The relay cover cannot be removed from the

base during normal operation. To maintain

the initial characteristics, do not remove the

relay cover.

➂ Use the relay in environments free from

condensation, dust, sulfur dioxide (SO

2

), and

hydrogensulde(H

2

S).

➃ The RF1V relay cannot be washed as it is not

asealedtype.Alsomakesurethatuxdoes

not leak to the PC board and enter the relay.

2. Connecting outputs to electronic circuits:

When the output is connected to a load which

responds very quickly, such as an electronic

circuit, contact bouncing causes incorrect opera-

tion of the load. Take the following measures

into consideration.

➀ Connect an integration circuit.

➁ Suppress the pulse voltage due to bouncing

within the noise margin of the load.

3. Do not use relays in the vicinity of strong mag-

neticeld,asthismayaffectrelayoperation.

4. UL and CSA ratings may differ from product

rated values determined by IDEC.

6. Notes on PC Board Mounting

When mounting 2 or more relays on a PC board, •

keep a minimum spacing of 10 mm in each

direction. If used without spacing of 10 mm,

rated current and operating temperature differs.

Consult IDEC.

Manual soldering: Solder the terminals at 400°C•

within 3 sec.

Auto-soldering: Preliminary heating at 120°C •

within 120 sec. Solder at

260°C±5°C within 6 sec.

Becausetheterminalpartislledwithepoxy•

resin, do not excessively solder or bend the

terminal. Otherwise, air tightness will degrade.

Avoid the soldering iron from touching the relay •

coverortheepoxylledterminalpart.

Useanon-corrosiveresinux.

(090319)