Owner's manual

Table Of Contents

- Cover

- Please Read Before Use

- CAUTION

- CE Marking

- Table of Contents

- Safety Guide

- Caution in Handling

- 1. Overview

- 2. Installation

- 3. Wiring

- 3.1 Basic Structure

- 3.2 Configuration Using a SIO Converter

- 3.3 Configuration Using an Isolated PIO Terminal Block

- 3.4 Configuration Using Both SIO Converter and Isolated PIO Terminal Block

- 3.5 Specifications of I/O Signals

- 3.6 I/O Signals for PIO Pattern 1 [3 Points] (Air Cylinder)

- 3.7 I/O Signals for PIO Pattern 0 [8 Points]

- 3.8 I/O Signals for PIO Pattern 2 [16 Points] (Setting by Zone BoundaryParameters)

- 3.9 I/O Signals for PIO Pattern 3 [16 Points] (Setting in Zone Fields in thePosition Table)

- 3.10 Emergency-Stop Circuit

- 3.11 Extension Cable

- 4. Electrical Specifications

- 5. Data Entry

- 6. Operation in the “3 Points (Air Cylinder)” Mode

- 7. Operation in the “8 Points” and “16 Points” Modes

- 7.1 How to Start

- 7.2 Position Table and Parameter Settings Required for Operation

- 7.3 How to Execute Home Return

- 7.4 Home Return and Movement after Start (16 Points)

- 7.5 Positioning Mode (Back and Forth Movement between Two Points)

- 7.6 Push & Hold Mode

- 7.7 Speed Change during Movement

- 7.8 Operation at Different Acceleration and Deceleration Settings

- 7.9 Pause

- 7.10 Zone Signal

- 7.11 Incremental Moves

- 7.12 Notes on Incremental Mode

- 8. Parameter Settings

- 9. Troubleshooting

- 10. Maintenance and Inspection

- 11. Appendix

- Change History

27

2. Installation

18

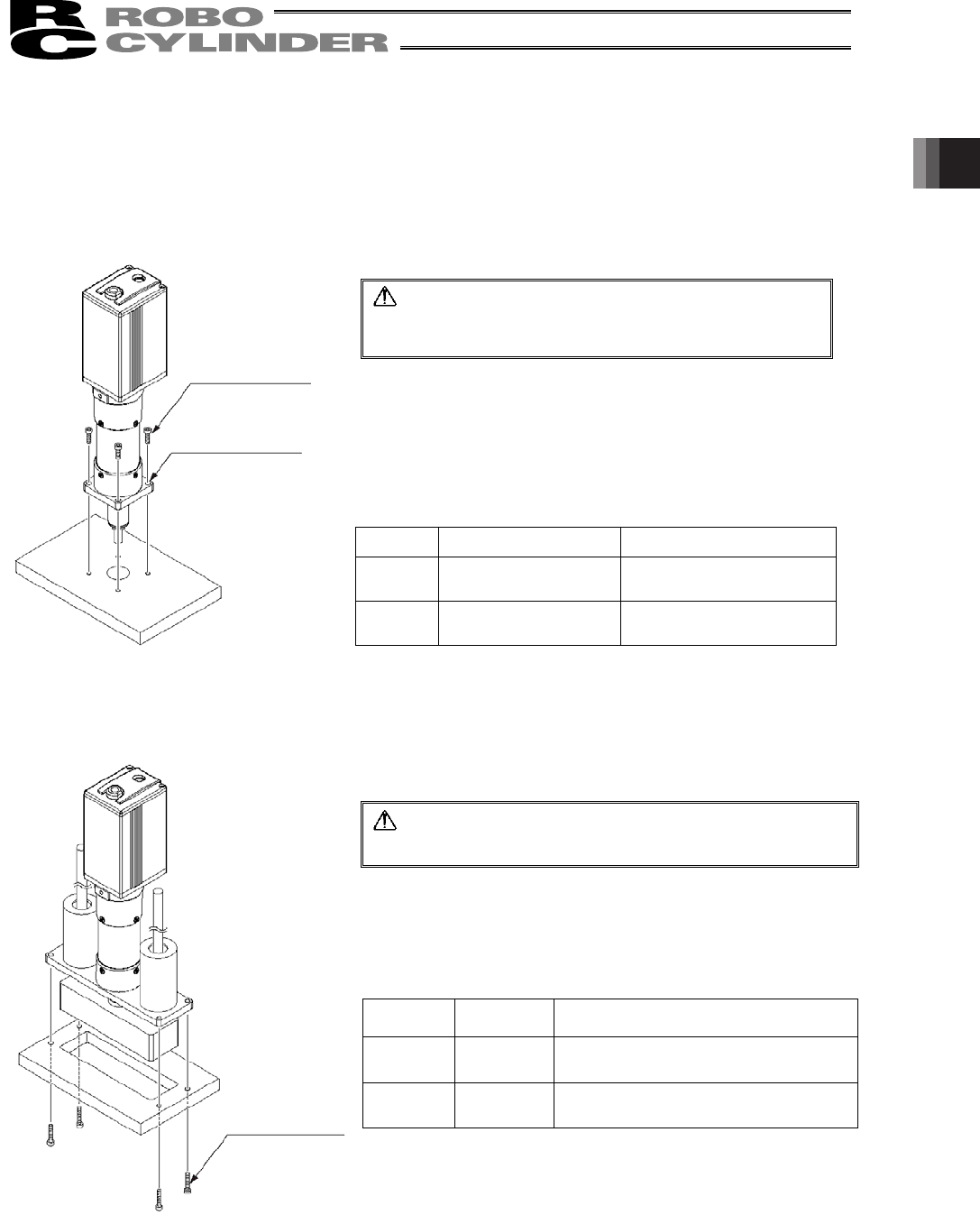

2.2.2 Rod Type

A rod-type actuator can be installed in the following two ways:

z Affixing with a flange

Install the actuator by tightening from the motor end side with hex cap bolts using the holes provided in the flange.

Caution: If the actuator is installed horizontally, exercise

caution not to let the actuator receive

excessive forces.

Flange tightening bolts

Model Nominal thread size Tightening torque

RA6C M5 3.4 Nm (0.35 kgfm)

RA7C M6 5.4 Nm (0.55 kgfm)

z Affixing through holes in a flange

Caution: If the actuator is installed horizontally, exercise

caution not to let the actuator receive excessive

forces.

Flange tightening bolts

Model

Nominal

thread size

Tightening torque

RGD6C M5

Steel bolt-bearing surface: 7.3 Nxm

Aluminum bolt-bearing surface: 3.4 Nxm

RGD7C

M6

Steel bolt-bearing surface: 12.3 Nxm

Aluminum bolt-bearing surface: 5.4 Nxm

Hex cap bolt

Hole in flange

Hex cap bolt