Owner's manual

Table Of Contents

- Cover

- Please Read Before Use

- CAUTION

- CE Marking

- Table of Contents

- Safety Guide

- Caution in Handling

- 1. Overview

- 2. Installation

- 3. Wiring

- 3.1 Basic Structure

- 3.2 Configuration Using a SIO Converter

- 3.3 Configuration Using an Isolated PIO Terminal Block

- 3.4 Configuration Using Both SIO Converter and Isolated PIO Terminal Block

- 3.5 Specifications of I/O Signals

- 3.6 I/O Signals for PIO Pattern 1 [3 Points] (Air Cylinder)

- 3.7 I/O Signals for PIO Pattern 0 [8 Points]

- 3.8 I/O Signals for PIO Pattern 2 [16 Points] (Setting by Zone BoundaryParameters)

- 3.9 I/O Signals for PIO Pattern 3 [16 Points] (Setting in Zone Fields in thePosition Table)

- 3.10 Emergency-Stop Circuit

- 3.11 Extension Cable

- 4. Electrical Specifications

- 5. Data Entry

- 6. Operation in the “3 Points (Air Cylinder)” Mode

- 7. Operation in the “8 Points” and “16 Points” Modes

- 7.1 How to Start

- 7.2 Position Table and Parameter Settings Required for Operation

- 7.3 How to Execute Home Return

- 7.4 Home Return and Movement after Start (16 Points)

- 7.5 Positioning Mode (Back and Forth Movement between Two Points)

- 7.6 Push & Hold Mode

- 7.7 Speed Change during Movement

- 7.8 Operation at Different Acceleration and Deceleration Settings

- 7.9 Pause

- 7.10 Zone Signal

- 7.11 Incremental Moves

- 7.12 Notes on Incremental Mode

- 8. Parameter Settings

- 9. Troubleshooting

- 10. Maintenance and Inspection

- 11. Appendix

- Change History

153

10. Maintenance and Inspection

144

10. Maintenance and Inspection

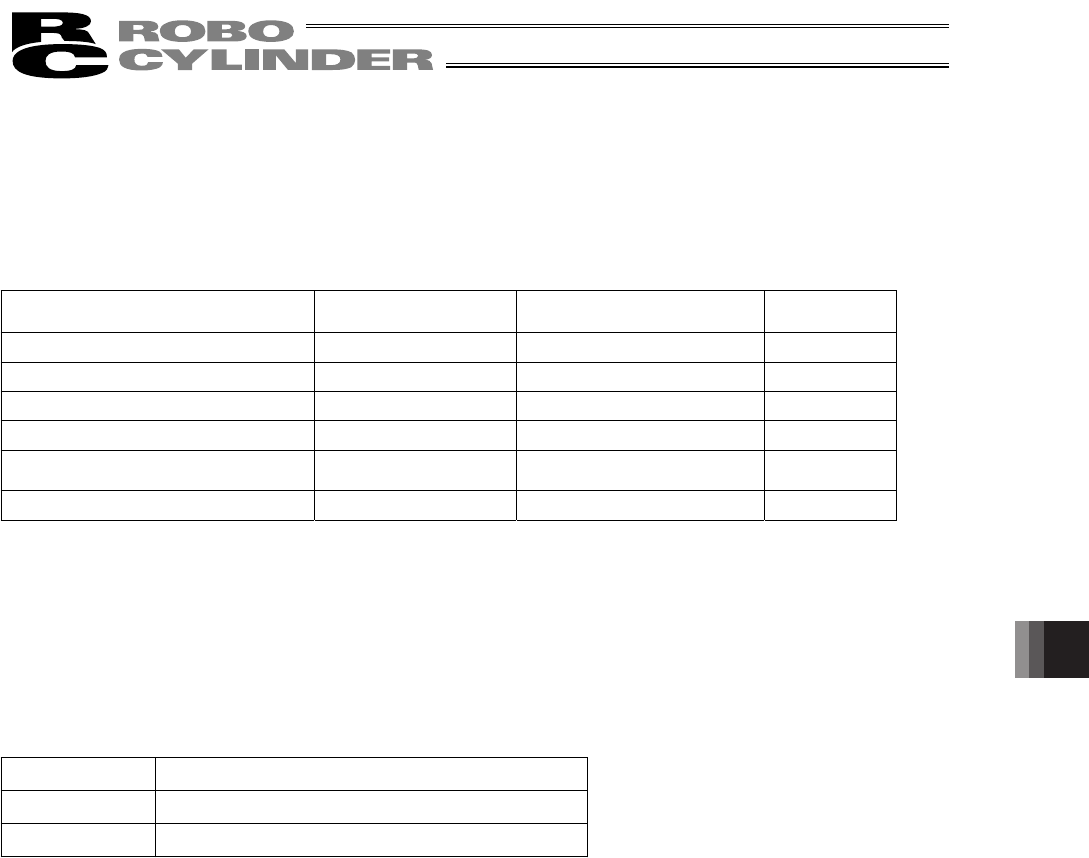

10.1 Inspection Items and Schedule

Perform maintenance and inspection per the schedule specified below.

This schedule assumes eight hours of operation a day. Shorten the inspection intervals if the utilization is higher, such

as when the actuator is operated continuously day and night.

Visual inspection of

appearance

Greasing Mo

del

Start-up inspection

{

After 1 month of operation

{

After 3 months of operation

{

{ (Rod slide surface) Rod type *1

Every 3 months thereafter

{

{ (Rod slide surface) Rod type *1

After 3 years of operation or 5,000

km of moving distance

{

{ (Guide/ball screw) Slider type *2

Every 1 year thereafter

{

{ (Guide/ball screw) Slider type *2

*1 With a rod-type actuator, grease the rod slide surface if the surface is found dry at the start-up inspection or

every three months.

*2 With a slider-type actuator, grease the guide and ball screw as necessary by considering the use environment,

condition, etc.

10.2 Visual Inspection of Appearance

Check the following items in the visual inspection:

Actuator Loose actuator-mounting bolts, etc.

Cables Damage, connector coupling

Overall Noise, vibration

10.3 Cleaning

x Clean the exterior as necessary.

x Wipe off dirt using a soft cloth, etc.

x Do not blow compressed air at high speed. Doing so may cause dust to enter the actuator through gaps.

x Do not use petroleum solvent, since it will damage the resin and coated surfaces.

x To remove significant soiling, wipe the area gently using a soft cloth, etc., moistened with neutral detergent.