Owner's manual

Table Of Contents

- Cover

- Please Read Before Use

- CAUTION

- CE Marking

- Table of Contents

- Safety Guide

- Caution in Handling

- 1. Overview

- 2. Installation

- 3. Wiring

- 3.1 Basic Structure

- 3.2 Configuration Using a SIO Converter

- 3.3 Configuration Using an Isolated PIO Terminal Block

- 3.4 Configuration Using Both SIO Converter and Isolated PIO Terminal Block

- 3.5 Specifications of I/O Signals

- 3.6 I/O Signals for PIO Pattern 1 [3 Points] (Air Cylinder)

- 3.7 I/O Signals for PIO Pattern 0 [8 Points]

- 3.8 I/O Signals for PIO Pattern 2 [16 Points] (Setting by Zone BoundaryParameters)

- 3.9 I/O Signals for PIO Pattern 3 [16 Points] (Setting in Zone Fields in thePosition Table)

- 3.10 Emergency-Stop Circuit

- 3.11 Extension Cable

- 4. Electrical Specifications

- 5. Data Entry

- 6. Operation in the “3 Points (Air Cylinder)” Mode

- 7. Operation in the “8 Points” and “16 Points” Modes

- 7.1 How to Start

- 7.2 Position Table and Parameter Settings Required for Operation

- 7.3 How to Execute Home Return

- 7.4 Home Return and Movement after Start (16 Points)

- 7.5 Positioning Mode (Back and Forth Movement between Two Points)

- 7.6 Push & Hold Mode

- 7.7 Speed Change during Movement

- 7.8 Operation at Different Acceleration and Deceleration Settings

- 7.9 Pause

- 7.10 Zone Signal

- 7.11 Incremental Moves

- 7.12 Notes on Incremental Mode

- 8. Parameter Settings

- 9. Troubleshooting

- 10. Maintenance and Inspection

- 11. Appendix

- Change History

94

6. Operation in the “3 Points (Air Cylinder)” Mode <Practical Operation>

85

The relationships of movement command inputs/position complete outputs and corresponding position numbers are

shown below.

For easier identification, each input/output signal has a name similar to the naming convention used with air cylinders.

However, note that the target position is determined by the value set in the [Target position] field under each position

number. Therefore, changing the magnitude correlation of the settings in Nos. 0 to 2 will change the meanings of the

corresponding input/output signals.

Accordingly, the settings in the respective position numbers should match the semantic meanings of the

corresponding signal names used in this operation manual, unless doing so will pose a problem.

Input signal Output signal Target position

Rear end move (ST0) Rear end complete (PE0)

Setting in the [Target position] field under

position No. 0 Example: 5 mm

Front end move (ST1) Front end complete (PE1)

Setting in the [Target position] field under

position No. 1 Example: 390 mm

Intermediate point move (ST2) Intermediate point complete (PE2)

Setting in the [Target position] field under

position No. 2 Example: 200 mm

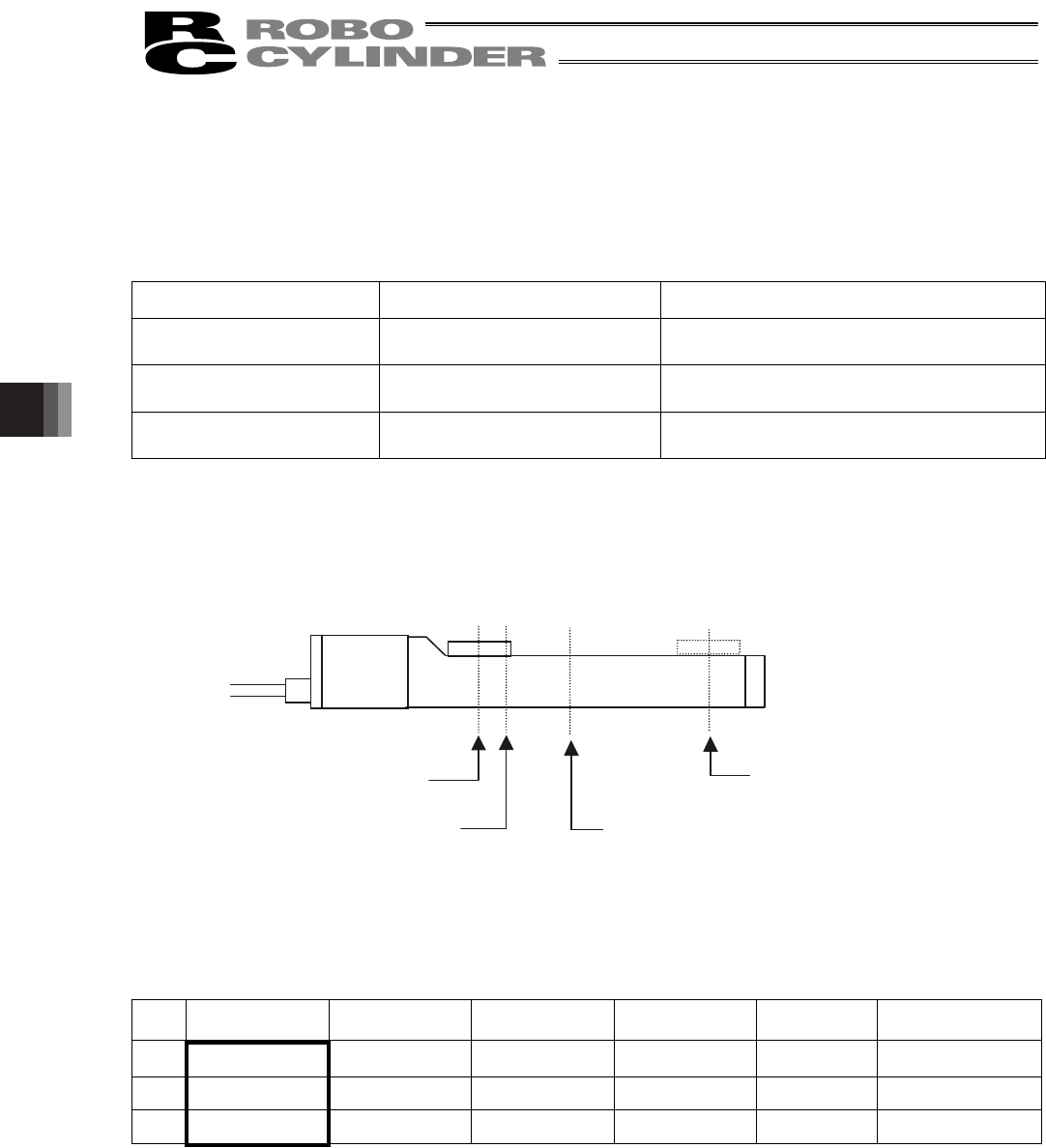

z Positioning relationships on the Robo Cylinder

This example assumes the use of a slider type actuator with a 400 mm stroke.

[Motor side] [Counter-motor side]

z Position table (Field(s) within thick line must be entered.)

No.

Position

[mm]

Speed

[mm/s]

Acceleration

[G]

Deceleration

[G]

Push

[%]

Positioning band

[mm]

0 5.00 500.00 0.30 0.30 0 0.10

1 390.00 500.00 0.30 0.30 0 0.10

2 200.00 500.00 0.30 0.30 0 0.10

Home (0 mm)

Rear end complete (5 mm)

Front end complete (390 mm)

Intermediate point complete (200 mm)