User Manual

GENERAL EM -7

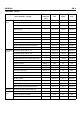

Items

Standa

rd

([]ind

icates standard

diamet

er)

Limit

Correct

ive

action

Outer side valve Spring

Free height

Load installed

Winding direction

Out of squareness

Inner side valve spring

Free length

Load installed

Winding direction

Out of squareness

66.1mm

26.5~29

.3kg

To th e r i

ght

1.5mm

60.0mm

11.5~12

.7kg

Left sid

e

1.5mm

63mm

23.7kg

2.1mm

57mm

10.3kg

2.1mm

Replac

e

Cylinde

rblock

Cylinder

bore

To r s i o n o

f upper crankcase

Flatness

of gasket surface

Outofsqu

areness of gasket surface

Clearanc

e between tappet and crankcase tappet hole

104.00~104.03mm

Below 0.07mm

0.07mm

0.05mm

[28] 0.045~0.096mm

0.2mm

0.2mm

Replace

Clearanc

e between piston ring and piston ring groove

No.1 ring

No.2 ring

Oil ring

0.106~0.170mm

0.07~0.11mm

0.03~0.07mm

0.2mm

0.15mm

0.15mm

Replace the

piston ring

Piston ri

ng end gap

No.1 ring

No.2 ring

Oil ring

0.25~0.40mm

0.50~0.65mm

0.20~0.40mm

1.0mm

1.5mm

1.0mm

Replace

Average protrusion of piston

Gasket grade A

Gasket grade B

Gasket grade C

0.466~0.526mm

0.526~0.588mm

0.588~0.648mm

Measure

the average

protrusion and

replace the

gasket with the

corresponding

grade gasket

Piston

Piston outer diameter

Clearance between piston and cylinder sleeve

103.91~1

03.92mm

0.080~0.

130mm

Repair wi

th

oversize

or

replace

Piston pin

Outer diameter of piston pin

Clearance between piston pin and piston pin hole

Clearance between piston pin and connect-

ing rod end bush

37.994~3

8.00mm

0.007~0.

021mm

[38] 0.02

5~0.046mm

0.05mm

0.1mm

Replace

Replace b

ush

Cylinder

sleeve

Inner dia

meter

Outofrou

ndness

Out of cyl

inderness

104.00~1

04.03mm

0.005mm

0.015mm

100.25mm

Below

0.01mm

Below

0.03mm

Repair wi

th

oversize

or

replace

Cylinder head

Flatness of cylinder head bottom

Length from cylinder head top to bottom

Below 0.1

mm

94.9~95.

1mm

0.2mm

94.6mm

Repair or

replace