User Manual

EM -4 ENGINE MECHANIC AL SYSTEM

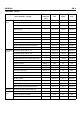

PISTON RING

Piston has two compression rings and one oil ring. All

sliding surfaces of rings are coated with hardened chrome.

Compression ring No. 1

Compression ring No. 2

Oil ring No. 3

SUDEM7008L

CRANKSHAFT

1. Crankshaft is forged with high-strength alloy built in

with balance weight.

2. Pin, journal and oil seal sliding-surface are hardened

with high frequency heat treatment to raise the resis-

tance against frictional wear.

3. Through oil passage at the pin and journal, oil lubri-

cates main bearing. Oil flows to the pin for the lubri-

cation of connecting rod bearing.

4. Crankshaft pulley and crankshaft gear are installed

at the front end of crankshaft. The crankshaft pulley

drives alternator and water pump using V-belt.

5. Crankshaft damper pulley absorbs the distorting vi-

bration of crankshaft.

Journal

Crankshaft gear

Crankshaft

damper pulley

Pin

Oil passage

SUDEM7009L

6. Crankshaft gear (1) drives camshaft gear (2), idler

gear A (3), idler gear B (4), supply pump gear (5) and

oil pump gear (6).

5

4

3

2

6

1

SUDEM7010L

CRANKSHAFT M AIN BEARING

Upper main bearing has oil groove and oil hole which

matches with oil hole of the crankshaft.

Dividedtypethrustplateisinstalledtothebothendsofthe

last bearing (No.5).

Upper main bearing (No. 5)

Upper main bearing (No. 1)

Lower main bearing

Thrust plate

SUDEM7011L