User's Manual

4 • 1. Getting Started DSP500 Series Wheel Alignment Sensors

1.5 Charging Sensor Batteries (XF Sensors Only)

Each sensor contains a 12VDC sealed lead acid rechargeable battery. To get the

maximum life out of the batteries in the sensors, follow these three rules:

1. If the sensors are not in use, charge them.

2. Switch sensors “OFF” during charging if you are using cables.

3. Charge for eleven to thirteen hours, and/or provide an extended charge time

(24 hours or longer) at least once a week.

NOTE: Make sure the main power switch at the rear of the console is

left “ON” and the outlet that supplies power to the aligner is on.

“K”, “R”, and “P” cabinets are equipped with a computer, printer

and CRT, but still provide power to the charging stations when

using the standby power switch. This standby power switch is

located on the front or side of the cabinet.

The “S”, “SMT-CKD” and “W” cabinets do not have a standby

power switch. The computer, printer, and CRT may be switched

“OFF” independently from the main power switch.

To prevent premature degradation of battery performance, the charger has to replace

125% of the energy that was removed from the battery. It is not necessary to fully

discharge the batteries before charging. However, it is important they be charged

fully.

Charging information:

To recharge the batteries when the sensors are not in use, place the wheel adaptor

sensor assemblies on the cabinet storage hanger and leave the main aligner power on.

The “shoe” on which the sensor hangs acts as the – (neg) terminal, and the insulated

contact is the + (pos) terminal.

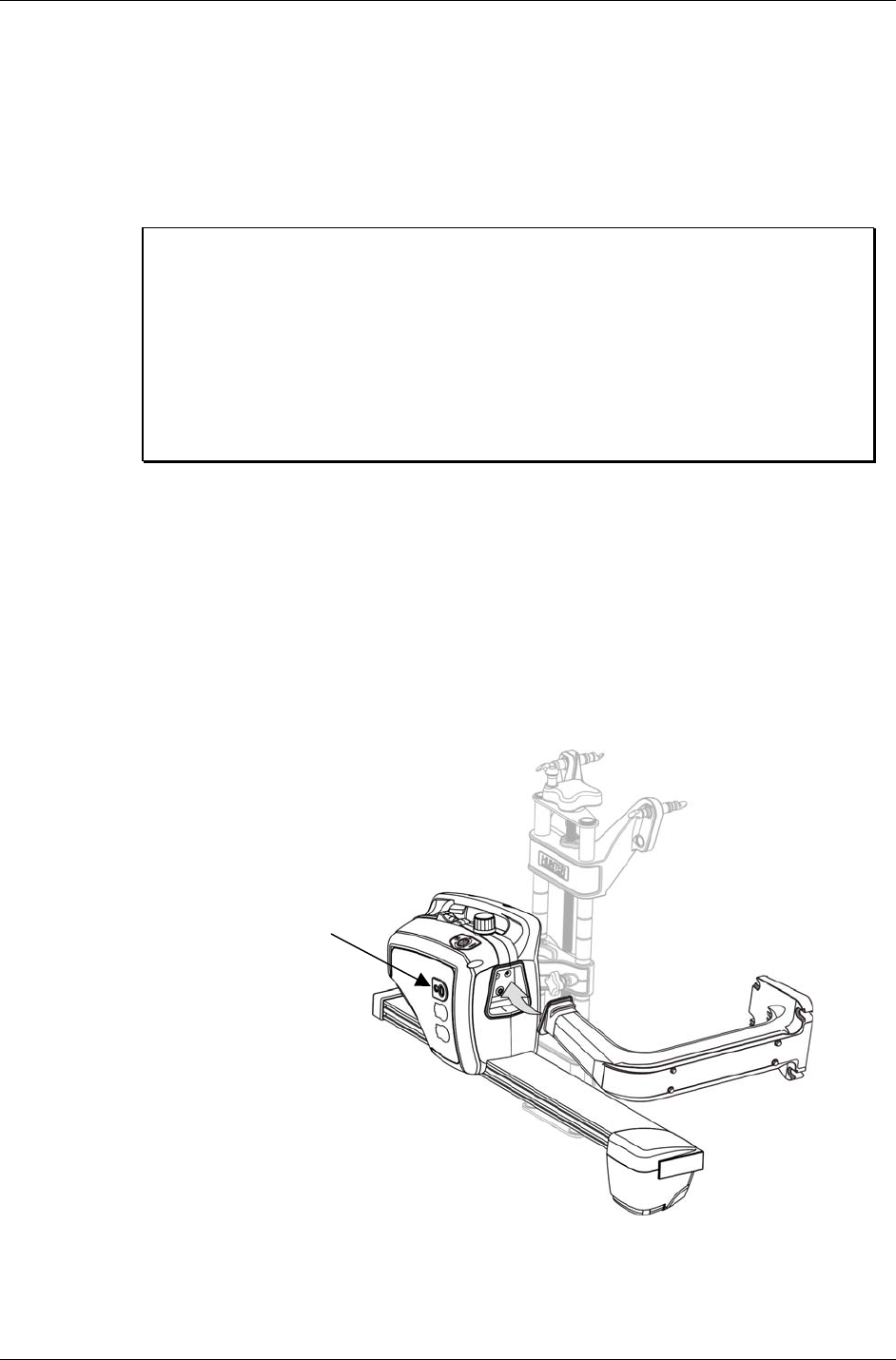

CHARGE INDICATOR

Any time batteries are being charged the charge indicator light on the sensor will be

illuminated.