Miller`s

They take data from the web in a fully automated operation.

We don’t pre-ight anything, which further accelerates throughput.”

The revolution in photography

The company also processes 50,000 rolls of lm each year.

That’s down from a peak of 2.4 million, and illustrates the

change the industry has undergone.

“In fact, digital is about 25 percent of our work,” Coleman says.

“75 percent of our business is silver halide. All individual prints

are produced on our 100+ silver halide printers.

“Fifteen years ago, we just produced photographs,” says

Coleman. “Today, we have thousands of product options and

add hundreds of new ones each year. The HP Indigo digital

presses have helped with that, and also given us the potential

to develop further oerings using features like the seven-color

option, textured prints, digital matte, and other added

value eects.”

With the range of Miller’s product line and its 24-hour

turnaround times, reliability is essential.

“Our operators are HP trained and capable of resolving most

issues quickly,” Coleman explains. “HP is very responsive and

knowledgeable. We normally run two extended shifts for a

12 – 13 hour work day. During peak season, we run 24/7 and

have a trained service engineer on the oor all night to keep the

presses running.”

Dierentiation through nishing

Given the large number of photo specialty products, Miller’s

has a comprehensive range of nishing equipment.

“Our production lines are arranged by product for maximum

eciency, so the right nishing equipment is near each press,”

Martin explains. “We have die-cutters for luxury cards; perfect

binders, trimmers, saddle stitchers and spiral binders for

calendars; side-sewing for hard-cover books; glue padding for

notepads, and so on. We also have some specialty equipment

like foil stamping for cards, UV coaters, laminators and

magnetic strips.

“We are very pleased with the presses, the workow and the

service. We’ll be adding more space and more digital presses

in the future. We’ve grown every year since we focused on

processing in 1970. We can only continue that by staying

ahead,” Coleman concludes.

“ We had customers

screaming for

photo products on

substrates that our

dry toner digital

printers couldn’t

deliver. Our HP

Indigo 7000-series

Digital Presses are

able to; they have

helped us develop

our product range

and do things we

couldn’t before.”

– Todd Coleman, president and

COO, Miller’s Professional Imaging

© Copyright 2014 Hewlett-Packard Development Company, L.P. The information contained herein is subject to

change without notice. The only warranties for HP products and services are set forth in the express warranty

statements accompanying such products and services. Nothing herein should be construed as constituting an

additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

4AA5-4750ENW, September 2014

Get connected.

hp.com/go/graphicarts

Share with colleagues.

Installing 10 HP Indigo 7000-series Digital Presses in a

three year period is a big investment by any standard, and

demonstrates not only faith in the technology but also in

continued market growth.

In spite of enormous changes in the industry, communications

and social customs, photographs have remained the preferred

way to keep and share experiences and memories.

Beginning in 1939 when Bill Miller began his wedding and

portrait photography business in Pittsburg, Kansas, ‘staying

ahead’ has been a driving principle. 75 years later, Miller’s

Professional Imaging, incorporating the online consumer

service Mpix.com, has 400 employees, hundreds of photo

specialty products and customers throughout North America.

“Miller’s serves professional photographers and is based in

Columbia, Missouri. Mpix, for consumers, is in Pittsburg, Kansas,”

explains Todd Coleman, president and COO, Miller’s Professional

Imaging, and grandson of the founder. “It was all built from a

potential disaster and a sound understanding of the future.”

The pursuit of excellence

After World War II, in which he was a distinguished

cinematographer whose footage is still seen in documentaries,

Miller continued his photography business and began

processing lm for professional photographers. In 1970,

his studio burned down and he was faced with the decision

whether to rebuild, or focus on his processing enterprise,

which had not been aected by the re. Miller chose the latter

and today Miller’s Professional Imaging is a $120+ million,

debt-free company, handling millions of orders annually.

“We are in constant pursuit of excellence,” Coleman says. “This

applies to the quality of our photographic work as well as to the

products we oer professional photographers and customers.

We’re pretty much control freaks and do everything ourselves,

in-house.”

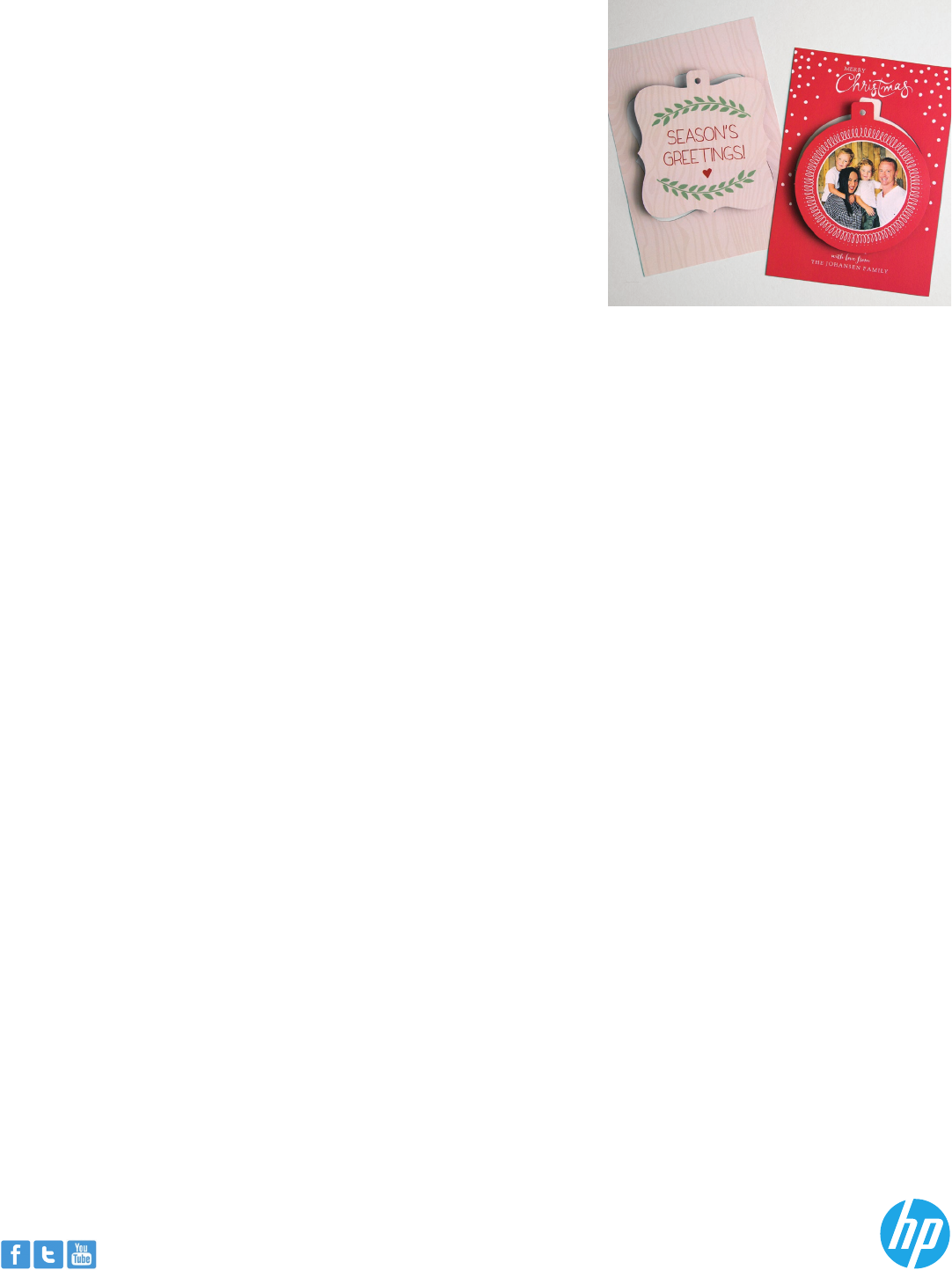

The list of products available from Miller’s covers all the

expected items and formats as well as the more novel,

like wooden USB drives, die-cut and pop-out greeting cards,

custom printed DVDs, and metal and acrylic wall art.

“Mpix has a scaled-down oering for consumers, but all

orders are turned around within 24 hours,” Coleman says.

“Orders received by 3:00pm are out the door by 6:00pm.

That happens in August when we handle 36,000 orders

per week, or in December when there are 130,000.”

Miller’s 10 HP Indigo digital presses are essentially dedicated

to greeting card and calendar production, as well as certain

specialty items, handling about 50 percent of the orders.

“We have the most vocal customers in the world, and when we

began receiving a big demand for products requiring heavier

stocks, we knew we’d have to respond,” explains Coleman.

“Our existing eet of 10 toner-based printers couldn’t handle

the heavier stocks and we also knew that our competition had

HP Indigo presses, so, wanting to stay ahead, we talked to HP.”

The company now has three of its HP Indigo digital presses

in Columbia, for professional work, and seven in Pittsburg,

meeting the demand from Mpix customers.

“We have HP SmartStream servers running with custom-built

HP servers,” says John Martin, production manager at Miller’s,

in Columbia. “The HP SmartStream server handles the

imposition and the HP custom-server drives the JDF workow.