User's Manual

Table Of Contents

- CONTENTS

- I. Specifications

- 1. Icemaker

- KM-1300SAH

- KM-1300SWH

- KM-1300SRH

- KM-1300SAH3

- KM-1300SWH3

- KM-1300SRH3

- 2. Condensing Unit

- URC-12F

- II. General Information

- 1. Construction

- [a] KM-1300SAH, KM-1300SAH3

- [b] KM-1300SWH, KM-1300SWH3

- [c] KM-1300SRH, KM-1300SRH3

- 2. Controller Board

- [a] Solid-State Control

- [b] Controller Board

- [c] Sequence

- [d] Controls and Adjustments

- [e] Checking the Controller Board

- III. Technical Information

- 1. Water Circuit and Refrigerant Circuit

- [a] KM-1300SAH, KM-1300SAH3

- [b] KM-1300SWH, KM-1300SWH3

- [c] KM-1300SRH, KM-1300SRH3

- 2. Wiring Diagrams

- [a] KM-1300SAH, KM-1300SWH

- [b] KM-1300SRH

- [c] KM-1300SAH3, KM-1300SWH3

- [d] KM-1300SRH3

- 3. Timing Chart

- 4. Performance Data

- [a] KM-1300SAH

- [b] KM-1300SWH

- [c] KM-1300SRH

- [d] KM-1300SAH3

- [e] KM-1300SWH3

- [f] KM-1300SRH3

- IV. Service Diagnosis

- 1. No Ice Production

- 2. Evaporator is Frozen Up

- 3. Low Ice Production

- 4. Abnormal Ice

- 5. Other

- V. Removal and Replacement of Components

- 1. Service for Refrigerant Lines

- [a] Refrigerant Recovery

- [b] Evacuation and Recharge [R-404A]

- 2. Brazing

- 3. Removal and Replacement of Compressor

- 4. Removal and Replacement of Drier

- 5. Removal and Replacement of Expansion Valve

- 6. Removal and Replacement of Hot Gas Valve and Line Valve

- 7. Removal and Replacement of Evaporator

- 8. Removal and Replacement of Water Regulating Valve - Water-Cooled Model Only

- 9. Adjustment of Water Regulating Valve - Water-Cooled Model Only

- 10. Removal and Replacement of Condensing Pressure Regulator (C.P.R.) -

- 11. Removal and Replacement of Thermistor

- 12. Removal and Replacement of Fan Motor

- 13. Removal and Replacement of Water Valve

- 14. Removal and Replacement of Pump Motor

- 15. Removal and Replacement of Spray Tubes

- VI. Maintenance and Cleaning Instructions

- 1. Preparing the Icemaker for Long Storage

- 2. Cleaning and Sanitizing Procedures

- [a] Cleaning Procedure

- [b] Sanitizing Procedure - Following Cleaning Procedure

- 3. Maintenance

65

2. Cleaning and Sanitizing Procedures

IMPORTANT

Ensure all components, fasteners and thumbscrews are securely in place after any

maintenance or cleaning is done to the equipment.

WARNING

1. HOSHIZAKI recommends cleaning this unit at least once a year. More frequent

cleaning, however, may be required in some existing water conditions.

2. To prevent injury to individuals and damage to the icemaker, do not use ammonia

type cleaners.

3. Always wear liquid-proof gloves to prevent the cleaning and sanitizing solutions

from coming into contact with skin.

IMPORTANT

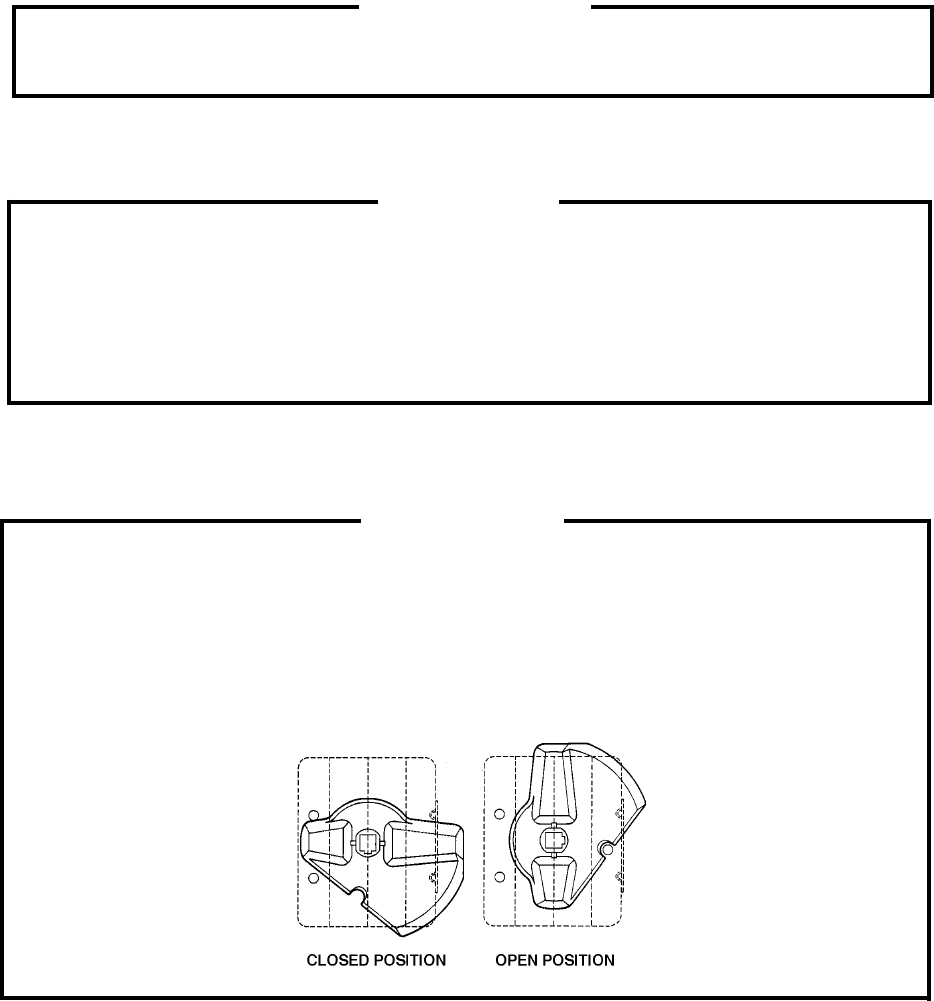

1. The cleaning valve is used to allow solution flow to the inside of the evaporator

during the cleaning and sanitizing operation. It should be closed for all icemaking

operation. The compressor will not operate unless this valve is completely closed.

2. To open the cleaning valve, the valve handle should be parallel to the valve body.

To close the valve, the valve handle should be at a right angle to the valve body.