Specifications Sheet

Cabinet Construction

Refrigeration System

618 Hwy, 74 S., Peachtree City, GA 30269 | TEL 800-438-6087 | FAX 800-345-1325 | www.hoshizakiamerica.com

© HOSHIZAKI AMERICA, INC.

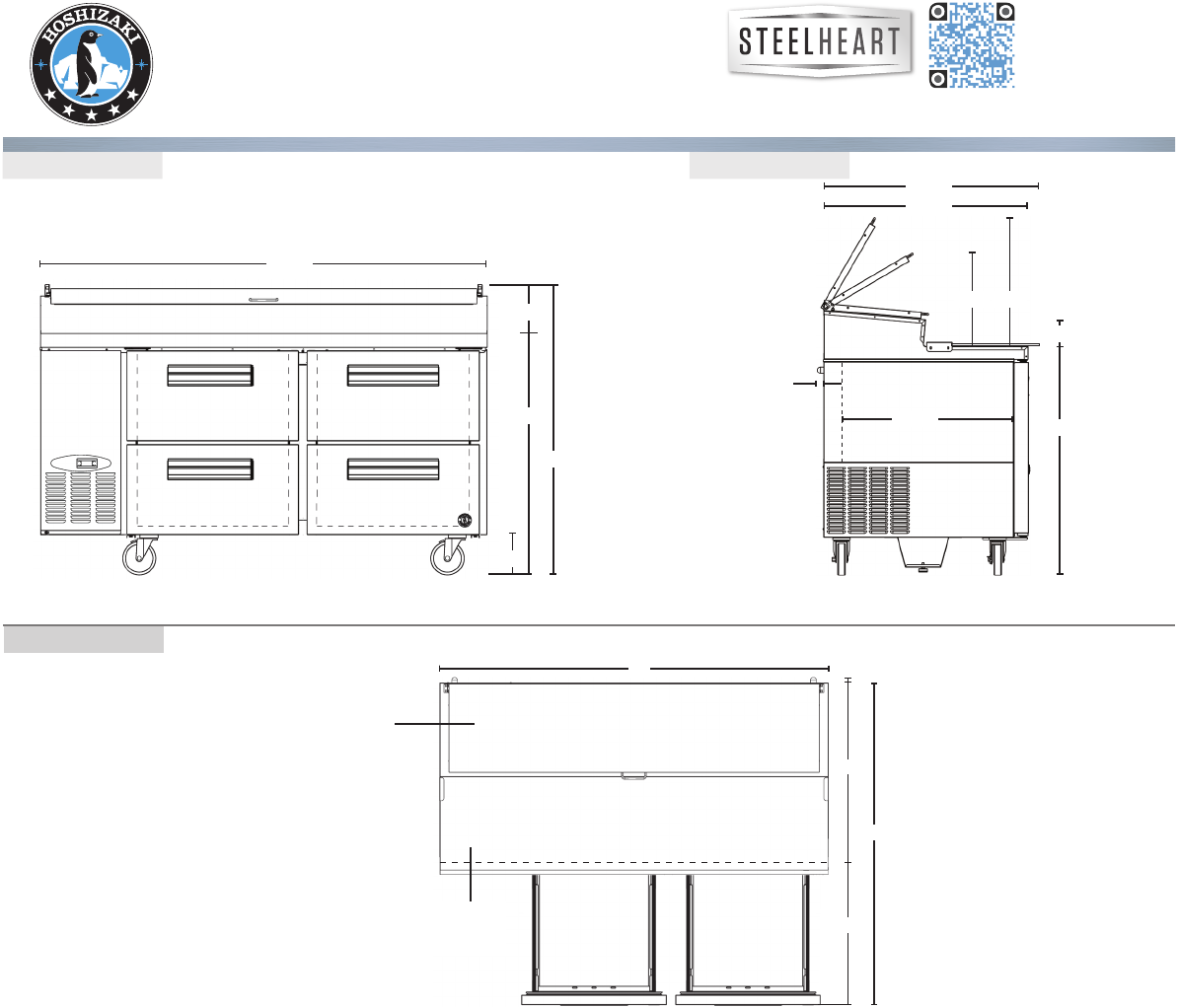

PLAN VIEW

SIDE VIEW

FRONT VIEW

PR67A-D4

11/05/18

Item # 13498

PR67A-D4

Front breathing refrigeration system allows unit to be built into any enclosure with zero clearance at the side or rear. The high efficiency refrigeration system is self-contained

with an epoxy electrocoated (E-Coat) evaporator coil for extended life. Condensate removal is accomplished with an energy efficient non-electric evaporation system. A capillary

tube controls the flow of environmentally friendly R290 refrigerant through the evaporator. Unit uses a heated, time initiated defrost to eliminate any ice on the evaporator coil. An

innovative ducted air distribution system distributes air evenly around food product in the rail. Engineered to maintain NSF-7 temperatures in 100°F ambient. (Certified to NSF-7

temperatures in 86°F ambient.) Pizza preparation tables are supplied with a full complement of N.S.F. approved polycarbonate plastic, 1/3rd size pans, 4” deep and stainless steel

adapter bars. 115 volt units are equipped with a ten foot cord and NEMA rated plug (20.0 amps or less).

The exterior cabinet top, front, and sides, are constructed of high quality stainless steel. The exterior back and bottom are constructed of coated steel. The cabinet interior

back and sides are stainless steel with an ABS ceiling and stainless steel floor. Mounted on anodized aluminum pilasters the shelves are adjustable in 1/2” increments. Cabinet

walls and doors are insulated with 2” of foamed in place polyurethane. 6” polyolefin stem casters (two with brakes) are standard. The raised refrigerated rail is constructed of

stainless steel interior and exterior (except back is galvanized steel). The rail is air cooled and utilizes a unique patent pending ducted air distribution system to distribute air

evenly and maintain product temperature at safe levels. The rail will accommodate 1/6th, 1/3rd, ½ and full size pans 6” deep. Pans are located 1.5” below the front of the rail to

assist in access to food product. An insulated, stainless steel, one piece hinged, lid is standard. Pizza preparation table is supplied with a 67” x 19” x 1/2” thick N.S.F. approved

white polyethylene cutting board.

Drawer fronts are constructed of high grade stainless steel inside and out and are insulated with 2” CFC free foamed in place polyurethane. Each drawer accommodates (2) 12”

X 20” X 6” deep pans (pans by others). Drawer module frames are formed of 16 gauge stainless steel all welded construction and securely fastened in the cabinet. The drawer

slides are constructed of 14 gauge stainless steel with delrin nylon rollers to prevent metal to metal contact between the drawer slides and help reduce wear. The drawer slides

have a dynamic load capacity of 250 pounds. Drawers are provided with a one-piece extruded aluminum flush mount handle. Snap-in magnetic drawer gaskets are durable and

easily removed for cleaning.

Drawer Construction

67” Pizza Prep Table with Drawers

35.17”

67”

43.5”

7.45”

36”

6”

1”

36”

1”

67”

32.3”

26.42”

4.2”

14.5” 20.3”

56.5”

31.25”

25.25”

67” x 19” x 1/2” thick

polyethylene cutting

board

(9) - 1/3rd size pans

and adapter bars

standard