Service Manual

Table Of Contents

- Important Safety Information

- I. Construction and Water/Refrigeration Circuit Diagram

- A. Construction

- B. Icemaking Unit

- C. Water/Refrigeration Circuit Diagram

- II. Sequence of Operation and Service Diagnosis

- A. Sequence of Operation Flow Chart

- 1. Icemaking and Drain Cycle

- 2. Shutdown

- B. Service Diagnosis

- 1. Ice Production Check

- 2. Diagnostic Procedure

- C. Control Board Check

- D. Bin Control Check

- E. Float Switch Check and Cleaning

- F. Diagnostic Tables

- III. Controls and Adjustments

- A. Control Board

- B. Controls and Adjustments

- 1. Default Dip Switch Settings

- 2. Infrared Sensor Shutdown Delay (S1 dip switch 1, 2, 3).

- 3. Drain Frequency Control (S1 dip switch 4)

- 4. Continuous Dispensing Timer (S1 dip switch 5 & 6)

- 5. Bin Control Selector (S1 dip switch 7)

- 6. Agitation and Ice Purge Timer (S1 dip switch 8)

- 7. Mechanical Shutdown Delay (S1 dip switch 9)

- 8. Factory Use (S1 Dip Switch 10)

- C. Power Switch and Control Switch

- IV. Refrigeration Circuit and Component Service Information

- A. Refrigeration Circuit Service Information

- B. Component Service Information

- V. Maintenance

- VI. Disposal

- VII. Technical Information

- A. Specification & Performance Data Sheets

- 1. F-300BAJ

- 2. F-500BAJ

- B. Wiring Diagrams

- 1. F-300BAJ

- 2. F-500BAJ

39

B. Component Service Information

NOTICE

• When replacing a component listed below, see the notes to help ensure proper

operation.

• When replacing evaporator assembly and water circuit components, make sure

there are no water leaks after the repair is complete.

• Seal bolts must be replaced once removed because seal material is one-time

use only. If new seal bolts do not have preapplied threadlocker, apply Loctite243

or equivalent threadlocker to seal bolt threads. Tighten to the torque value listed

below.

Torque for F-300BAJ and F-500BAJ: 11.1 ft-lb/15 N·m. Tighten 2 times. Allow at

least 5 sec. in between each tightening.

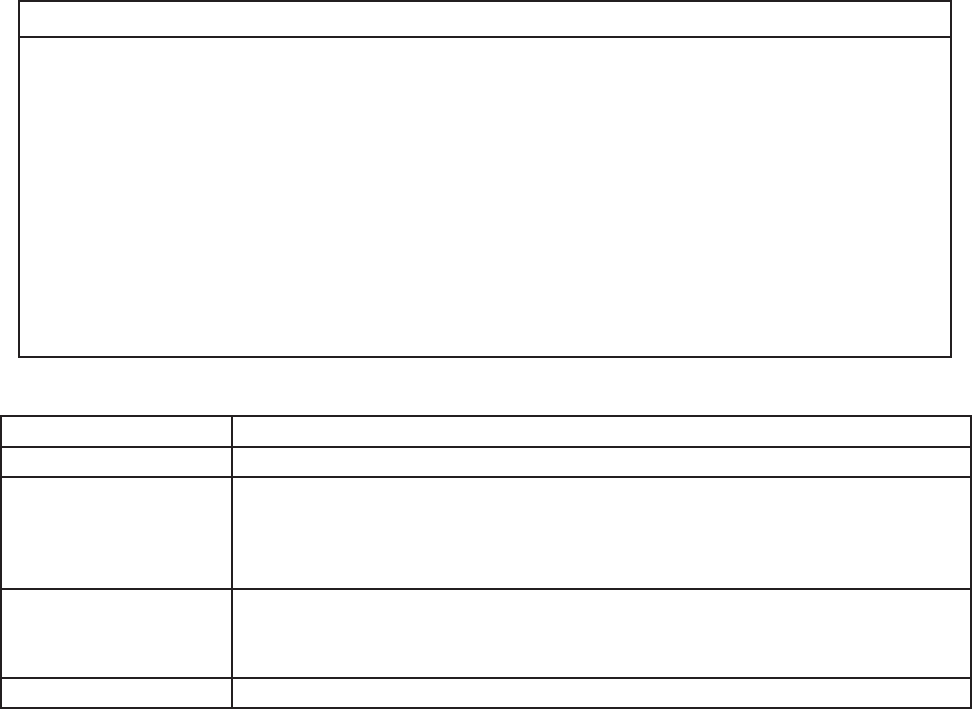

Component Notes

Compressor • Install a new drier, start capacitor, and start relay.

Upper and Lower

Bearings

• Inspect the upper bearing for wear. See "IV.B.1. Upper Bearing Wear Check."

Replace if necessary.

• When replacing the upper bearing it is advised to also change the lower bearing

at the same time.

Evaporator • Install a new drier.

• Inspect the mechanical seal and O-ring prior to installing the new evaporator.

Ifworn, cracked, or scratched, the mechanical seal should also be replaced.

Gear Motor • Install a new gear motor capacitor.