user manual

6

VI. STANDARD UNIT FEATURES — 6

1

⁄2 AND 7

1

⁄2

CABINET — Galvanized steel with a durable powder coat paint finish. The cabinet front

and sides are formed into a one piece unitized design with stamped louvers to provide

protection for the condenser coils.

SERVICE ACCESS — Control box with separation between line and control voltages,

as well as compressor and other refrigerant controls are accessible through removable

t

op and side panels (without affecting normal operation of unit).

Condenser fan motors are mounted on removable top panels which bring the motors out

to you and expose entire condenser coil for cleaning.

COMPRESSOR — Hermetically sealed with internal high temperature protection and

d

urable insulation on motor windings. The compressor is mounted on rubber grommets

to reduce vibration and noise.

CONDENSER COILS — Constructed with copper tubes and aluminum fins mechanical-

ly bonded to tubes for maximum heat transfer capabilities. All coil assemblies are leak

t

ested.

REFRIGERANT CONNECTIONS — All field sweat joints are made external of the unit

and are located close to the ground for a neat looking installation.

LOW AMBIENT CONTROL — A pressure sensitive fan cycling control allows operation

of units down to to 0°F.

HIGH PRESSURE CONTROL — Manual reset control deactivates system if abnormally

high pressure occurs.

LOW PRESSURE CONTROL — Automatic reset control deactivates system if abnor-

mally low pressure or refrigerant loss occurs.

SERVICE VALVES — Standard on liquid line and suction line. Allows outdoor section

to be isolated from indoor coil.

FILTER DRIER — Standard, field installed. Helps maintain system cleanliness.

CONDENSER FAN MOTORS — Direct-drive, PSC single-phase motors.

TRANSFORMER — Step down type, from Line to 24 volts. (Refer to Figure 2.)

CONTACTOR — (Refer to Figure 2.) The contactor is an electrical switch which oper-

ates the compressor and condenser fans. Its 24 volt coil is activated through the High

Pressure Control and Low Pressure Control on a call for cooling.

CAPACITORS — Help provide starting torque necessary to boost the condenser fan

motors to operating speed by directing their stored energy to the starter winding in step

with the running winding.

EQUIPMENT GROUND — Lug for field connection of ground wire.

TESTING — All units are run tested at the factory prior to shipment.

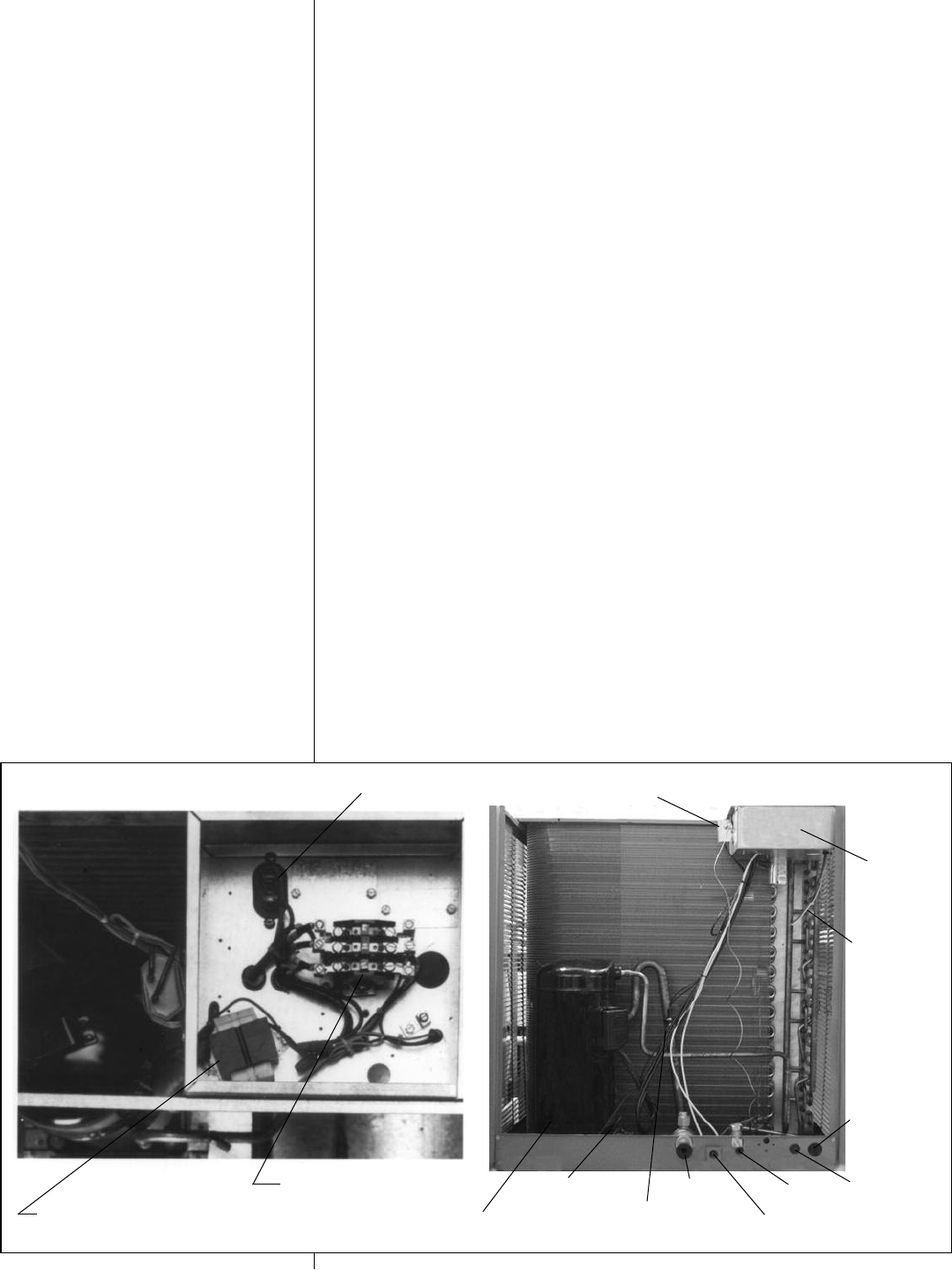

CONTROL TRANSFORMER

SCROLL

COMPRESSOR

LOW

PRESSURE

SWITCH

CRANKCASE

HEATER

SUCTION

VALVE

HIGH PRESSURE

SWITCH

LIQUID

VALVE

LOW VOLTAGE

ENTRY

HIGH VOLTAGE

ENTRY

LOW VOLTAGE

CONNECTION

LOW AMBIENT

CONTROL

CONTROL

BOX

COMPRESSOR CONTACTOR

FIGURE 2

6

1

⁄2 & 7

1

⁄2 TON FEATURES

CAPACITOR