user manual

D. REPLACEMENT UNITS

To prevent failure of a new condensing unit, the existing evaporator tubing system must

be correctly sized and cleaned or replaced. Care must be exercised that the expansion

device is not plugged. For new and replacement units, a liquid line filter drier should be

installed and refrigerant tubing should be properly sized. Test the oil for acid. If positive,

a suction line filter drier is mandatory.

IMPORTANT: WHEN REPLACING AN R-22 UNIT WITH AN R-410A UNIT, EITHER

REPLACE THE LINE SET OR ENSURE THAT THE EXISTING LINE SET IS THOR-

OUGHLY CLEANED OF ANY OLD OIL OR DEBRIS.

E. EVAPORATOR COIL

REFER TO EVAPORATOR COIL MANUFACTURER’S INSTALLATION INSTRUC-

TIONS:

IMPORTANT: The manufacturer is not responsible for the performance and operation of

a mismatched system, or for a match listed with another manufacturer’s coil.

XVII. EVACUATION AND CHARGING

The evacuation of any system component that has been exposed to atmosphere or lost

its charge is essential before charging. Never attempt to operate a system while it is

under a vacuum.

15

!

CAUTION

Only use evaporators approved for use on R-410A systems. Use of existing R-22

evaporators can introduce mineral oil to the R-410A refrigerant forming two differ-

ent liquids and decreasing oil return to the compressor. This can result in com-

pressor failure.

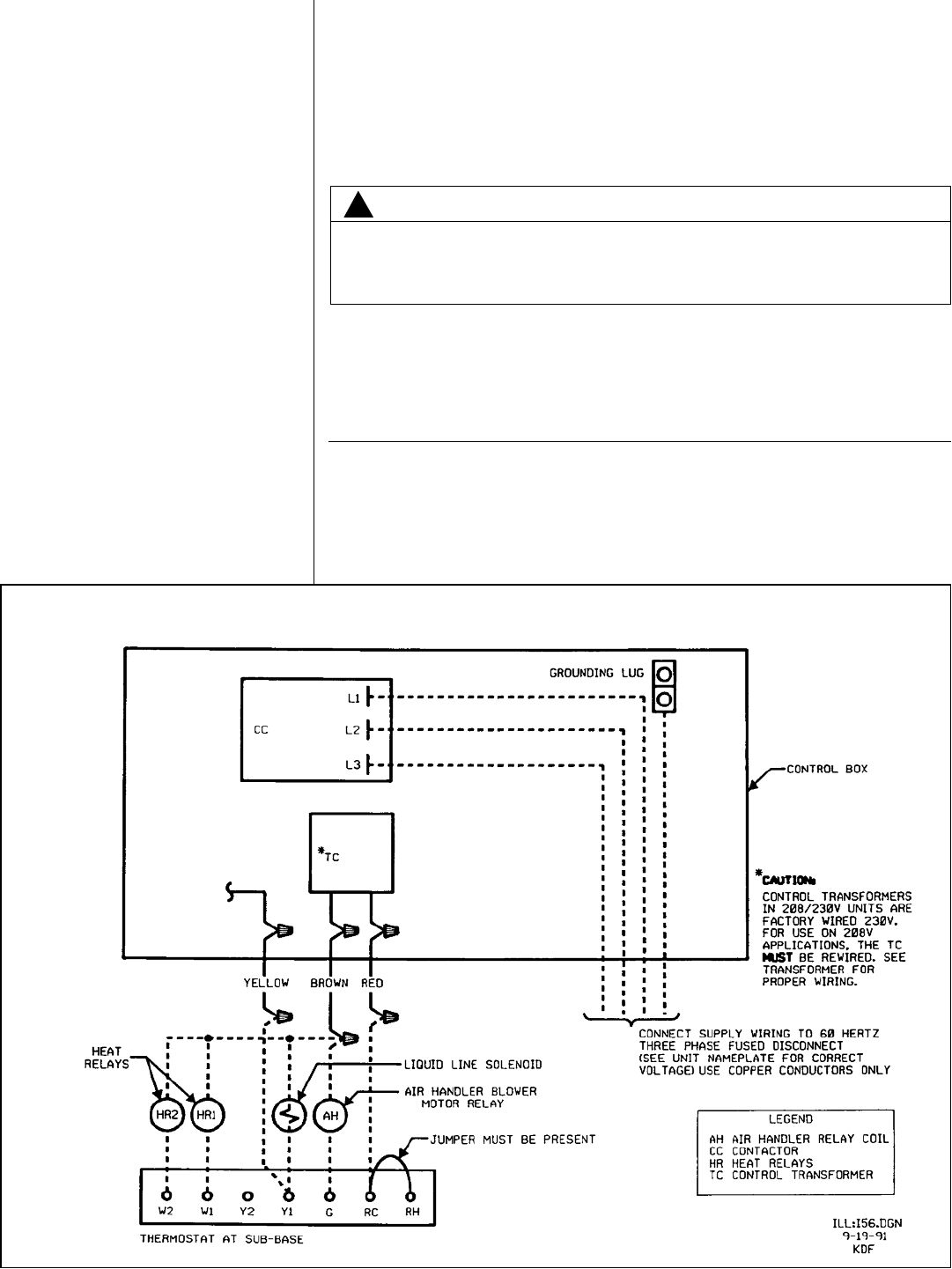

FIGURE 9

TYPICAL FIELD WIRING CONNECTIONS — 6

1

⁄2 AND 7

1

⁄2 TON