Manual

Table Of Contents

- Introduction

- SECTION 1 Getting Started

- CHAPTER 1 HALTECH IG5 INSTALLATION

- 1.1 Overview

- 1.2 Installation Summary

- 1.3 Expanded Installation Guide

- 1.3.1. Manifold Absolute Pressure (MAP) Sensor

- 1.3.2. Coolant Temperature Sensor

- 1.3.3. Inlet Air Temperature Sensor

- 1.3.4. The Throttle Position Sensor (TPS)

- 1.3.5. Mounting the Igniter

- 1.3.6. Route Wiring Harness and Connect Sensors

- 1.3.7. Power Relays

- 1.3.8. Electronic Control Unit (ECU)

- 1.3.9. Flying Leads

- 1.3.10. Install and connect any Optional Outputs

- 1.3.11 Connect the Trigger Sensor

- 1.3.12 Connect the ECU

- CHAPTER 2 GETTING ONLINE

- CHAPTER 3 ENGINE IDENTIFICATION

- CHAPTER 4 USING HALTECH SOFTWARE

- CHAPTER 5 STARTING THE ENGINE

- CHAPTER 1 HALTECH IG5 INSTALLATION

- SECTION 2 Other Adjustable Features

- SECTION 3 Software Features

- SECTION 4 IG5 Optional Outputs

- CHAPTER 12 SOFTWARE ACCESS

- CHAPTER 13 AUXILIARY OUTPUTS

- 13.1 Description

- 13.2 Turbo Waste Gate Control (TWG)

- 13.3 Dual Intake Valve Control (DIV)

- 13.4 Torque Converter Lockup (TCC)

- 13.5 Electric Thermatic Fan Control (TF)

- 13.6 Electric Intercooler Fan Control (IF)

- 13.7 Shift Light Illumination (SL)

- 13.8 Anti-Stall Solenoid Control (AS)

- 13.9 Turbo Timer (TT)

- 13.10 NOS Switch

- SECTION 5 Appendices

76

C.2.2 Optical Sensors

Optical sensors are often used in original equipment and may be directly connected to the IG5.

These devices require three connections:

Power (normally +12v)

Ground

Trigger output

Often distributors with this type of sensor have a rising edge trigger at 70 degrees.

Many distributors used in electronic ignition systems are fitted with mechanical and/or

vacuum advance mechanisms. These mechanisms must be locked so that the IG5 receives a

an input trigger signal with fixed relationship to crankshaft position. If you elect to rotate the

distributor housing when setting the timing relationship of the trigger signal to the crankshaft

position (the trigger angle) , read Appendix D, Rotor Phasing, first.

C.2.3 Magnetic Reluctor Sensors

Many distributors used in electronic ignition systems are fitted with mechanical and/or

vacuum advance mechanisms. These mechanisms must be locked so that the IG5 receives an

input trigger signal with fixed relationship to crankshaft position. If you elect to rotate the

distributor housing when setting the timing relationship of the trigger signal to the crankshaft

position (the trigger angle), read Appendix D, Rotor Phasing first. The magnetic reluctor is

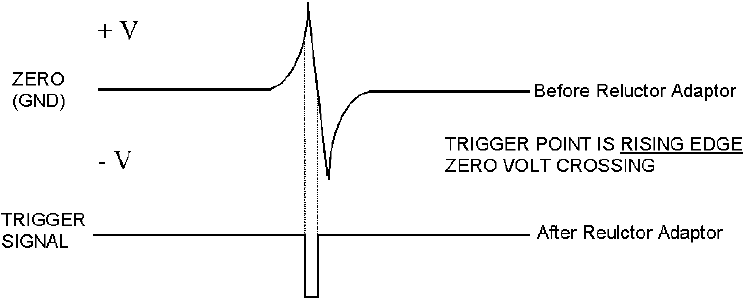

used in distributors as well as on crank trigger units. These give a sinusoidal output signal

(see Figure E.3.5) that must be modified to a square wave with a reluctor adaptor to be used as

the trigger input signal for the IG5. Haltech can supply a Reluctor Adaptor for this purpose.

The Reluctor adaptor has two input channels; a Primary input and a Secondary input. The

Primary input is used for the main trigger, and the secondary is used for the Home or Road

Speed input. The Reluctor adaptor plugs directly into the input trigger connector on the main

harness in series with the Haltech ECU and the reluctor pick-up.

Figure E.3.5 Signal before and after reluctor adaptor

.