Manual

Table Of Contents

- Introduction

- SECTION 1 Getting Started

- CHAPTER 1 HALTECH IG5 INSTALLATION

- 1.1 Overview

- 1.2 Installation Summary

- 1.3 Expanded Installation Guide

- 1.3.1. Manifold Absolute Pressure (MAP) Sensor

- 1.3.2. Coolant Temperature Sensor

- 1.3.3. Inlet Air Temperature Sensor

- 1.3.4. The Throttle Position Sensor (TPS)

- 1.3.5. Mounting the Igniter

- 1.3.6. Route Wiring Harness and Connect Sensors

- 1.3.7. Power Relays

- 1.3.8. Electronic Control Unit (ECU)

- 1.3.9. Flying Leads

- 1.3.10. Install and connect any Optional Outputs

- 1.3.11 Connect the Trigger Sensor

- 1.3.12 Connect the ECU

- CHAPTER 2 GETTING ONLINE

- CHAPTER 3 ENGINE IDENTIFICATION

- CHAPTER 4 USING HALTECH SOFTWARE

- CHAPTER 5 STARTING THE ENGINE

- CHAPTER 1 HALTECH IG5 INSTALLATION

- SECTION 2 Other Adjustable Features

- SECTION 3 Software Features

- SECTION 4 IG5 Optional Outputs

- CHAPTER 12 SOFTWARE ACCESS

- CHAPTER 13 AUXILIARY OUTPUTS

- 13.1 Description

- 13.2 Turbo Waste Gate Control (TWG)

- 13.3 Dual Intake Valve Control (DIV)

- 13.4 Torque Converter Lockup (TCC)

- 13.5 Electric Thermatic Fan Control (TF)

- 13.6 Electric Intercooler Fan Control (IF)

- 13.7 Shift Light Illumination (SL)

- 13.8 Anti-Stall Solenoid Control (AS)

- 13.9 Turbo Timer (TT)

- 13.10 NOS Switch

- SECTION 5 Appendices

65

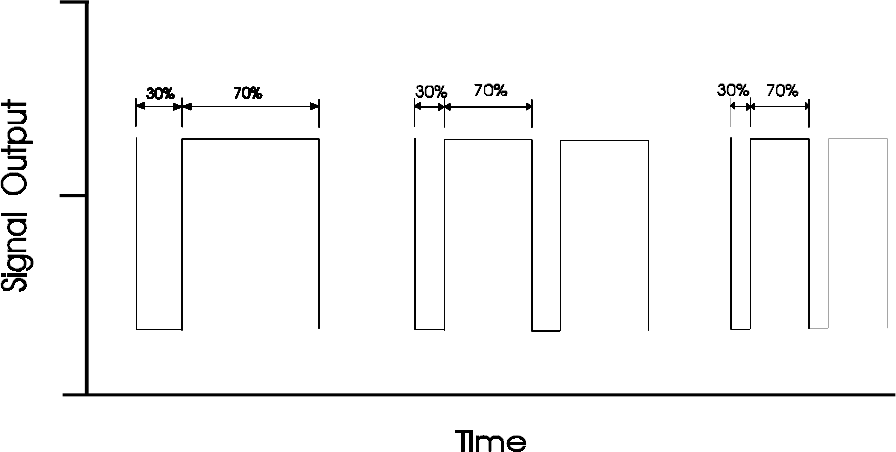

The duty cycle of a square wave is the ratio of its high time to its period. Eg. a 70/30 duty

cycle signal is high for 70% of its period and low for the remaining 30% regardless of

frequency, as shown in figure E7. Constant duty can also be used on aftermarket capacitive-,

inductive- or multiple-spark discharge systems such as MSD or Jacobs.

Figure E7. Illustrate constant duty against frequency

B 4.1 Constant Charge or “Dumb Igniters”

A "dumb" igniter is one that does not perform any sort of dwell control, thus the input signal

directly controls switching of the coil. A constant duty cycle signal should not be used with

this sort of igniter as it will overheat the coil at low frequencies (ie low revs), and not allow

enough charge time at high frequencies (ie high revs). Since the coil charge time remains

approximately the same regardless of frequency, it is appropriate for the ECU to constantly

charge the coil for exactly that time before firing.

The coil’s charge time can be determined from the coil -ve signal. When the coil switches on,

voltage drops to zero. As the coil charges, the voltage rises slightly, until a sharp rise where

the igniter current limits. Leaving the coil switched on any longer will not increase the energy

of the spark. See figure E8.

When the ignition firing frequency is high, there may not be enough time to charge the coil

completely. After firing the spark, the IG5 waits for a short period, then switches the coil on

again, regaining much of the energy lost in “ringing”. This break time should normally be 1

to 1.5ms.

(See previous warnings Re: setting the Ignition Output to Constant Charge or Constant Duty

to suit the particular type of ignition module (igniter). (Also see chapter 3.2).