Operating Instructions and Installation Instructions

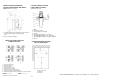

3.2. Safe distance between the fireplace insert and flammable material

If you have installed a fireplace insert within the room with flammable objects, flammability Class B,

C1 and C2, the safety distance from the front (or side glass surfaces) is 800 mm; for the other

directions, the safety distance is 400 mm. If the insert is installed within a room with flammable

objects, flammability class C3, the safety distances must be doubled. Kindly pay attention to the

information provided in Supplement 1 and 2. The most important installation dimensions are

shown in the product name plate.

3.3. Safe distance between the smoke flue and flammable material

The safety distance from the door frame lining and similar constructions made of flammable

materials, and from pipeline installations, incl. insulating elements is 200 mm (minimum). The

safety distance from the other parts of the constructions made of flammable materials is minimum

400 mm. This is applied to construction materials, flammable Class B, C1 and C2.(see Chart 3).

Kindly pay attention to the information provided in Supplement 2. More accurate classification is

available only if testing is performed for the particular product.

3.4. Directions for safe operation

For firing or kindling, never use any flammable liquid! It is forbidden to burn any plastic material,

wooden material combined with chemicals (chipboard, etc.) or domestic (unsorted) refuse containing

plastic, etc.

The insert must be operated by adults only! Never allow children in the room unattended. The

surface of the fireplace insert is overheated, especially the glassy components: any contact

will cause serious burnt. During the operation, occasional monitoring is required. For safe

operation and handling the regulation elements and the door closing devices, use the protective

glove (a part of the supply) .

Do not put any objects or tools on the insert while in operation or hot: flammable material may cause

fire.

The ashpan must be manipulated with utmost care. The ash may be very hot so there is danger of

serious burnt. Hot ash must not be in contact with flammable material – for example, while pouring it

into waste container.

The fireplace insert must be operated in compliance with the directions and

recommendations in the Operating Instructions. It is forbidden to modify the insert in any

way unless approved by the manufacturer.

Flammability class: selected construction materials

Flammability class

Construction materials

A – Incombustible construction

materials

Granite, sandstone, heavy concrete (porous), brick, ceramic

tiles, special plaster

B -

heavy fuels

Akumin, Heraklit, Lignos, Itaver

C1 – hardly inflammable Hardwoods, Hobrex panels, Sirkolit, hardened paper, formica

C2 – medium inflammable Chip boards, Solodur, cork parquet, rubber, floor covering

C3 - Flash fuels Wood-fibre boards, polystyrene, polyurethane

Chart 3

4. INSTALLATION AND CONNECTION TO THE CHIMNEY

Caution! For installation, relevant local regulations must be strictly adhered, including the

regulations related to national and European standards for this type of device.

4.1. Connection to the chimney or chimney insert

Connection of the fireplace insert to the chimney vent is subjected to approval by specialist chimney

company (ČSN 73 4201:2008), or to approval according to relevant regulations in force in the

country where the installation is made. Kindly pay attention to the information provided in

Supplement 2.

To provide proper function and operation, proper chimney effect in the smoke flue neck is

required. For the minimum stack draught, see the Technical Card for the particular product.

Insufficient chimney effect results in malfunction of the insert, excessive dirt on the glass, and

excessive clogging in the smoke flue system. The general heat capacity of the device is reduced. If

you feed the fire while proper chimney draught is not provided, flue gases may spread throughout

the room. For this reason, it is strictly recommended to have regular check done by a specialist

chimney company and maintain the heating device regularly. If the chimney effect is too high (over

20 Pa) it is recommended to install a suitable blocking device (for example, flue tube with a block).

Excessive chimney draught may cause troublesome operation, for example, too intensive burning,

high fuel consumption , damage on the heating device, etc.

Caution! It is recommended to connect fireplace inserts with rear outlet to the chimney by

direct connection (without an elbow element). Any other method of the connection should be

approved by a specialist chimney company.

4.2 Connecting the stove insert to the venting unit

It is recommended to connect the stove (insert) to a separate chimney vent. A joint chimney

vent may be used for the connection only if the safety regulations valid in the country of

installation allow doing so. It is forbidden to connect the stove (stove insert) to the same vent

used for a gas appliance. The minimum working height of the vent is 5 m. Depending on local

conditions, it is possible to connect the stove in the vent with a working height under 5 m

providing that the flue way calculation demonstrates that such a height is satisfactory.

Caution! (Provisions CSN 73 42 01: 2008)

The smoke flue vent diameter must not exceed the diameter of the chimney vent; it must not

be narrowed towards the chimney, either. If the calculation demonstrates that the vent

diameter of the smoke flue and chimney can be smaller than the flue neck diameter of the

device, the diameter of the smoke flue will be reduced just after the flue neck of the device, by

means of a short transition or abrupt.

4.3. Directions for smoke flue installation and safety

Connect the smoke outlet neck with the chimney in the shortest possible way so that the length of

the smoke path is no longer than 1.5 m. The smoke pipes and the elbow piece must be tightly

connected, overlapping at least 60 mm. Pay special attention to the fact that the joints must agree

with the flue outflow. The joint between the smoke flue and the smoke outlet neck must be drilled

together and fixed with a rivet or pin; the same is applied for the smoke pipes and the elbow. The

hole (entrance point) in the chimney must be provided with a metal stress ring (proper diameter).

The smoke flue should ascent towards the smoke uptake at angle approx. 10°.

4.4. Installation of the fireplace insert within the room

Before any installation work is started, you need to verify the floor (ceiling) load capacity. The load

conditions for the particular type of the device must be met (depending on the particular weight),

including the weight of the casing. It is recommend to contact a statics specialist. The fireplace insert

must be installed on a heat insulating base that overlaps the stove ground plan dimensions on the

sides and in the rear by at least 400 mm; the overlap in the front (the direction of the feeding

opening) is 800 mm. If a metal base is used, the thickness must be at least 2 mm.

For safety distances from the outer surface of the insert body and the smoke flue, see

Chapters 3.2 and 3.3.

Caution! Make sure you provide space enough for easy approach to the heating device, smoke flue

and chimney for the purpose of cleaning.

7 8