TP80-40/4 Shaft Seals Manual

Table Of Contents

61

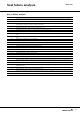

Shaft seals

Seal failure analysis

Key to failure analysis

Failure number Description of possible causes of failure

1

Seal opens due to differential expansion between stationary and rotating parts, caused by deposits preventing the rotating ring

from moving axially on the shaft.

2 Seal is not set to correct working length, resulting in no contact between face and seat.

3

Seal faces are running dry, resulting in overheating. High torque on seal faces made of hard materials can generate heat that can

be transmitted to elastomers, resulting in hardening and burning.

4 Closed pump outlet valve results in excessive temperature or failure no. 3.

5 Chemical reaction with an oxidizing agent, for instance nitric acid.

6 Insufficient flow to heat exchanger or cooled hollow seat, resulting in failure no. 3.

7 Overcompression due to incorrect assembly or incorrect working length, resulting in failure no. 3.

8

Solid particles, such as sodium hydroxide crystals, precipitate out of liquid across seal contact face. Use hard faces and/or flush

seal.

9

Volatile elements of liquid evaporate in seal gap, leaving highly viscous, sticky layers on seal faces. Use hard faces and double

seal.

10 Damage due to mishandling or overcompression.

11 Seal material not chemically resistant to liquid or contaminant.

12 Material has decomposed due to temperatures beyond limitations.

13 Seal has been exposed to pressure/temperatures in excess of limits.

14 Continual removal of passive film due to relative movement.

15 System pressure is below or close to vapour pressure.

16 Check bearings.

17 Liquid is saturated with scale.

18 Solid particles in liquid. Hard seal faces required.

19 Wrong assembly.

20 Longer life with cool top is expected.

21 Corrosion makes tungsten carbide appear mat grey or green.

22

By electrochemical deposition, metals such as copper may form on the seal face due to missing or poor electrical grounding of

pump.

23 In water of a conductivity below 5 microSiemens/cm, some SiC grades corrode. Use Qg seal faces.

24

Excessive heat dissipation may cause blistering of carbon. Reduce speed, spring load or pressure, or change to metal-

impregnated carbon.

25 Elastomers fitted on uncleaned surfaces.

26 Seat is misaligned, check for debris or deposits on seal faces.

27

Explosive decompression on account of heat build-up may take place due to misalignment, failure no. 26, or vibration, failure no.

16.

28 Start/stop at excessive system pressure with hard seal faces.