Service Manual User guide

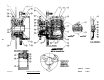

PLANETARY HUBS

ASSEMBLY PROCEDURE FOR MAJOR ASSEMBLY

Start with hub-spindle sub-assembly (1) with large open end up.

Assemble internal gear (2) onto the spindle of hub-spindle sub-assembly (1).

Place thrust washer (15) onto the spindle pilot of hub-spindle sub-assembly (1).

Place thrust bearing (16) onto spindle pilot of hub-spindle sub-assembly (1).

Place thrust washer (15) onto spindle pilot of hub-spindle sub-assembly (1).

Drop spacer washer (7) into spindle of hub-spindle sub-assembly (1).

Place spring (8) into spindle of hub-spindle sub-assembly (1).

Place spacer washer (7) into spindle of hub-spindle sub-assembly (1).

Secure retaining ring (9) into groove in spindle of hub-spindle sub-assembly (1).

Secure retaining ring (10) in groove on input shaft (11).

Place long splined end of input shaft (11) into spindle of hub-spindle hub-

assembly (1).

Slide thrust spacer (12) onto input shaft (11).

Put “O” ring (5) in hub counterbore of hub-spindle.

Place carrier sub-assembly (3) on a flat surface with large gears up. Find

marked (punch marked) teeth on the large gears. Rotate until the marks are in

a straight-up position. (See Figure).

Place ring gear (4) over large gears of carrier sub-assembly (3).

Holding ring gear (4) in mesh with large gears, pick-up carrier sub-assembly (3)

until marked hold is located over one of the counterbored holes in hub of hub-

spindle sub-assembly (1). Carrier sub-assembly (3) must rotate freely.

Put input gear (13) over input shaft (11) and meshing with large gears of carrier

sub-assembly. Be sure that input gear (13) relief is as shown. (See Figure).

Put “O” ring (5) into cover counterbore of cover sub-assembly (6). Hold “O”

ring in place with petroleum jelly or grease.

Place thrust washer (15) into carrier counterbore of carrier sub-assembly (3).

Place thrust bearing (16) into carrier counterbore of carrier sub-assembly (3).

Place thrust washer (15) into carrier counterbore of carrier sub-assembly (3).

Place cover sub-assembly (6) onto ring gear (4) with oil check plug in cover

sub-assembly (6) located 90 from oil fill plug in hub-assembly sub-assembly

(1).

1.

2.

3.

4.

5.

6.

7.

8.

9.

1 0 .

1 1 .

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

24