Service Manual User Manual

Table Of Contents

- 9020-7317 534B SERVICE MANUAL

- OPERATOR INSTRUCTIONS & LUBRICATION

- 8496 Operation & Lubrication Manual

- 8366 Operation & Lubrication Manual

- IMPORTANT SAFETY NOTICE

- INTRODUCTION

- SAFETY HIGHLIGHTS

- OPERATOR'S CAB

- CONTROL & INSTRUMENT IDENTIFICATION

- CHECKS & SERVICES BEFORE STARTING ENGINE

- ENGINE OPERATION

- WARM UP & OPERATIONAL CHECKS

- BRAKE SYSTEM

- STEERING SYSTEM

- DRIVE TRAIN

- MATERIAL HANDLING

- OPERATING PROCEDURES & TECHNIQUES

- PARKING

- STORAGE

- LUBRICATION & MAINTENANCE DIAGRAM

- 28327 Preventive Maintenance Chart

- HYDRAULIC SYSTEM

- 8497 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKE

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMP

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUIT

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUIT

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 8369 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKES

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMPS

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUITS

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUITS

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 81-515-009 Mico Sliding Caliper Disc Brakes Service Manual

- 81-600-001 Mico Guidelines for Installing Hydraulic Brake Components

- 81-950-016 Mico Brake Service Procedures

- 81-460-159 Mico Hydraulic Brake Valve

- 8497 System Operation Manual

- TESTING & ADJUSTING

- TROUBLE SHOOTING

- TRANSMISSION & TORQUE CONVERTER

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- HOW THE UNITS OPERATE

- SECTIONAL VIEWS AND PARTS IDENTIFICATION

- DISASSEMBLY OF TRANSMISSION

- CLUTCH DISASSEMBLY

- CLEANING AND INSPECTION

- REASSEMBLY OF TRANSMISSION

- SERVICING MACHINE AFTER TRANSMISSION OVERHAUL

- TOWING OR PUSH STARTING

- SPECIFICATIONS AND SERVICE DATA

- LUBRICATION

- TROUBLESHOOTING GUIDE

- TYPICAL TWO AND THREE SPEED POWER FLOW

- PRESSURE CHECK POINTS

- CLUTCH AND GEAR ARRANGEMENT

- DRIVE PLATE INSTALLATION

- TRANSMISSION TO ENGINE INSTALLATION PROCEDURE

- SPEED SENSOR BUSHING INSTALLATION

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- MISCELLANEOUS

- OPERATOR INSTRUCTIONS & LUBRICATION

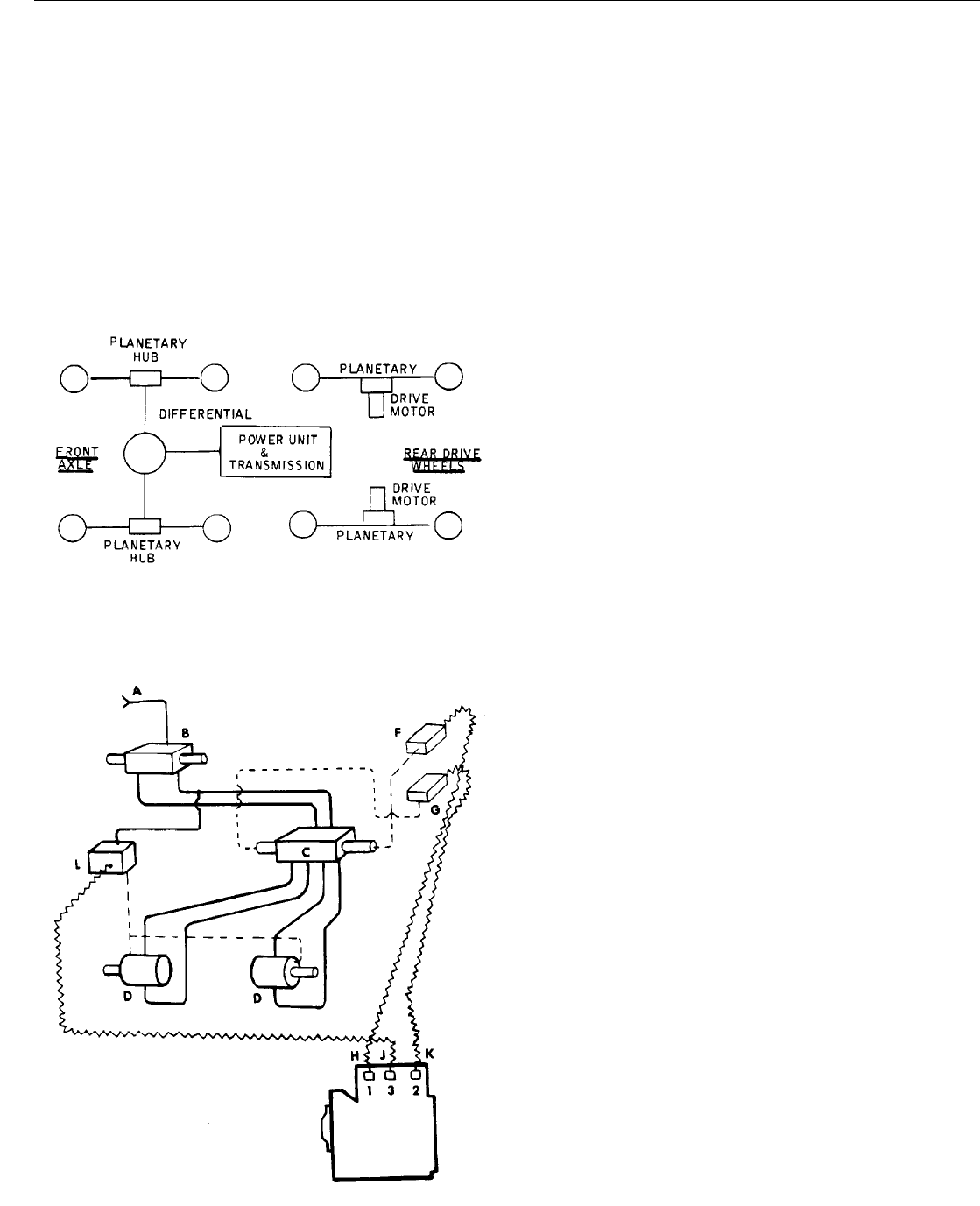

The 534B has a conventional front wheel drive, with

power from the engine. It has a torque converter and

transmission with a drive shaft and differential, and

a pair of planetary wheel ends. The rear drive uses

hydraulic oil to turn the motors and planetary hubs

at each rear wheel.

GRADALL LOED MATERIALS HANDLER 534B SYSTEM OPERATION

FRONT & REAR WHEEL DRIVE

The oil supply to the rear drive motors will vary

depending on the position of the gear selection lever.

The purpose of this is to coordinate the speed of the

rear wheels with the speed of the front wheels.

The 534B has a variety of options to control forward

and reverse, speed and power. An inching control

enables the operator to move the carrier slowly when

maneuvering or handling a load.

1. In first gear. A combination of low transmission

gear ratio to the front driving axle is used. The

rear drive uses parallel valving of hydraulics to

rear drive motors.

With the lever in Ist gear position, an electrical

contact is made at the sending unit (H) on the

transmission. The current activates the parallel

solenoid valve (F). This sends pilot oil to one end

cap of the series/parallel valve (C). The plunger

shifts into a parallel hydraulic mode and the

main pump oil is routed to the two drive motors

(D) equally. As the operator presses down on

the accelerator, the engine r.p.m. will increase

and so will the oil flow.

2. In second gear the gear ratios to the front axle are

changed to gain more speed and the hydraulic

valving is changed to series mode.

When the lever is shifted into the 2nd gear

position, an electrical current contact is made (J)

on the transmission. This activates the series

solenoid valve (G) and the opposite end cap of

the series/parallel valve (C) is pressurized. The

plunger shifts and the oil is routed in series to the

two drive motors. The motors turn faster to

match the speed of the front axle drive.

3. In third gear a higher gear ratio is used for

maximum speed in the front axle and the rear

drive is disengaged.

When in 3rd gear the rear wheel drive is not

functioning because the hydraulic drive can’t

keep up with the front wheel drive. Since the Ist

and 2nd gear solenoid valves are not activated,

the series/parallel valve (C) returns to neutral

and the oil in the drive motors simply circulates,

doing nothing. To reduce drag due to pumping a

full charge of rear motor oil, a cavitation valve

opens a direct line from the rear motors to tank.

It allows some of the oil to go to the tank,

therefore reducing the motor oil volume,

therefore reducing the drag.

13