Service Manual User Manual

Table Of Contents

- 9020-7317 534B SERVICE MANUAL

- OPERATOR INSTRUCTIONS & LUBRICATION

- 8496 Operation & Lubrication Manual

- 8366 Operation & Lubrication Manual

- IMPORTANT SAFETY NOTICE

- INTRODUCTION

- SAFETY HIGHLIGHTS

- OPERATOR'S CAB

- CONTROL & INSTRUMENT IDENTIFICATION

- CHECKS & SERVICES BEFORE STARTING ENGINE

- ENGINE OPERATION

- WARM UP & OPERATIONAL CHECKS

- BRAKE SYSTEM

- STEERING SYSTEM

- DRIVE TRAIN

- MATERIAL HANDLING

- OPERATING PROCEDURES & TECHNIQUES

- PARKING

- STORAGE

- LUBRICATION & MAINTENANCE DIAGRAM

- 28327 Preventive Maintenance Chart

- HYDRAULIC SYSTEM

- 8497 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKE

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMP

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUIT

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUIT

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 8369 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKES

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMPS

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUITS

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUITS

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 81-515-009 Mico Sliding Caliper Disc Brakes Service Manual

- 81-600-001 Mico Guidelines for Installing Hydraulic Brake Components

- 81-950-016 Mico Brake Service Procedures

- 81-460-159 Mico Hydraulic Brake Valve

- 8497 System Operation Manual

- TESTING & ADJUSTING

- TROUBLE SHOOTING

- TRANSMISSION & TORQUE CONVERTER

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- HOW THE UNITS OPERATE

- SECTIONAL VIEWS AND PARTS IDENTIFICATION

- DISASSEMBLY OF TRANSMISSION

- CLUTCH DISASSEMBLY

- CLEANING AND INSPECTION

- REASSEMBLY OF TRANSMISSION

- SERVICING MACHINE AFTER TRANSMISSION OVERHAUL

- TOWING OR PUSH STARTING

- SPECIFICATIONS AND SERVICE DATA

- LUBRICATION

- TROUBLESHOOTING GUIDE

- TYPICAL TWO AND THREE SPEED POWER FLOW

- PRESSURE CHECK POINTS

- CLUTCH AND GEAR ARRANGEMENT

- DRIVE PLATE INSTALLATION

- TRANSMISSION TO ENGINE INSTALLATION PROCEDURE

- SPEED SENSOR BUSHING INSTALLATION

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- MISCELLANEOUS

- OPERATOR INSTRUCTIONS & LUBRICATION

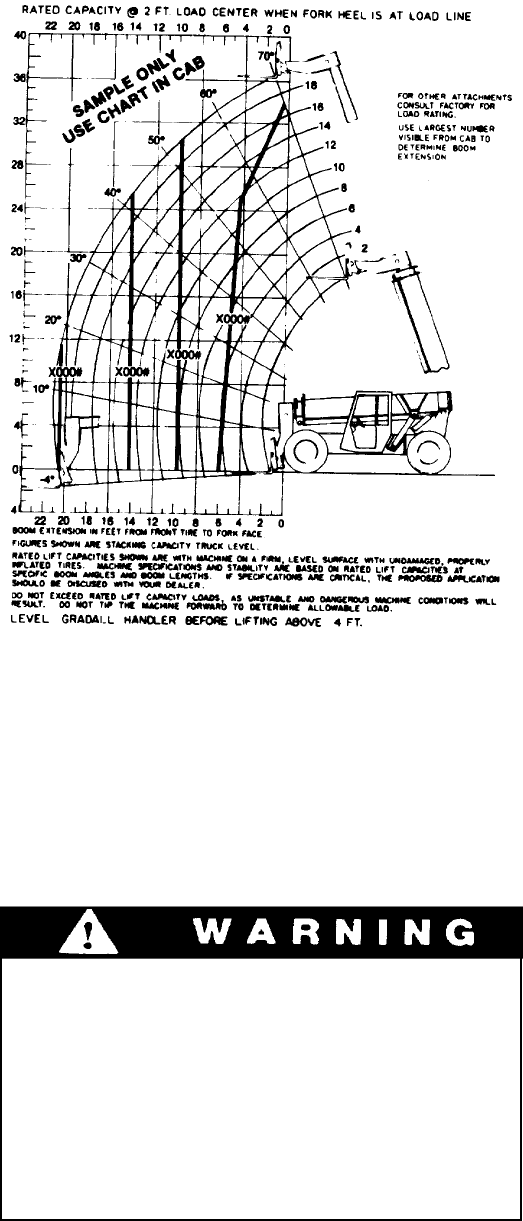

Boom Extension

Numbers across bottom of chart (0' to 22') and

numbers parallel to boom (2' to 18') represent boom

extension as measured from fully retracted position

to extended position. These numbers do not reflect

total boom length, only the number of feet of

extension from fully retracted position.

Number decals on boom section number two (4, 8

12, 16 and 20) relate directly to boom extension. The

largest number which can be read from operator’s

seat indicates total boom extension.

Boom extension relates to dimension “D” shown on

serial number plate.

Boom Angle

Numbers at ends of angled fines (4° to 70°)

represent angle of boom to horizontal as measured

from horizontal plane at ground level. Maximum

angles are 4° below horizontal with boom fully

lowered to 70° above horizontal with boom fully

raised.

A boom angle indicator is located on left side of

boom section number one to show boom angle. Be

sure machine is level from front to rear or indicator

will provide incorrect reading.

Load Center

Loads shown on rated capacity chart are based on

the load center being two feet above and two feet

forward of surfaces of horizontal forks as indicated

by dimensions “B” and “C” on serial number plate.

The load center of a load is the center of gravity of

the load. For regularly shaped loads of the same

material, such as a pallet of blocks, the center of

gravity can be located by measuring the load to find

its center. For irregular loads, or loads of dissimilar

materials, keep the heaviest part of the load as close

to the heel of the forks as possible.

In all cases, the load center must be centered

between the forks.

Load Limits

Some capacities shown on the rated capacity chart

are based on machine stability and some are based

on hydraulic lift capacity. The “common sense” or

“feel” an experienced operator might apply in

regard to “tipping loads” DOES NOT APPLY to

hydraulic load limits. Exceeding load limits can

cause a relief valve to open allowing the load to fall,

or in some cases, the machine to tip over.

Rated Capacity Chart

General

The rated capacity chart, located on left side of

dashboard, indicates maximum load capacities for

handlers equipped with standard carriage/fork

combination. These capacities apply only to the

standard carriage/fork combination and cannot be

used for other attachments.

All loads shown on rated capacity chart

are based on machine being on firm, level

ground; the forks being positioned evenly

on carriage; the load being centered on

forks; proper size tires being properly

inflated; and the handler being In good

operating condition. Machines having

8000 pound capacity must have tires

properly filled with calcium chloride.

Elevation:

Numbers at left side of chart (-4' to 40') represent

elevation at heel of horizontal fork as measured

from level ground. Maximum elevation with boom

fully raised and extended is 36 feet. Elevation relates

to dimension “A” shown on serial number plate

located on right cab wall.

16