Service Manual User Manual

Table Of Contents

- 9020-7317 534B SERVICE MANUAL

- OPERATOR INSTRUCTIONS & LUBRICATION

- 8496 Operation & Lubrication Manual

- 8366 Operation & Lubrication Manual

- IMPORTANT SAFETY NOTICE

- INTRODUCTION

- SAFETY HIGHLIGHTS

- OPERATOR'S CAB

- CONTROL & INSTRUMENT IDENTIFICATION

- CHECKS & SERVICES BEFORE STARTING ENGINE

- ENGINE OPERATION

- WARM UP & OPERATIONAL CHECKS

- BRAKE SYSTEM

- STEERING SYSTEM

- DRIVE TRAIN

- MATERIAL HANDLING

- OPERATING PROCEDURES & TECHNIQUES

- PARKING

- STORAGE

- LUBRICATION & MAINTENANCE DIAGRAM

- 28327 Preventive Maintenance Chart

- HYDRAULIC SYSTEM

- 8497 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKE

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMP

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUIT

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUIT

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 8369 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKES

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMPS

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUITS

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUITS

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 81-515-009 Mico Sliding Caliper Disc Brakes Service Manual

- 81-600-001 Mico Guidelines for Installing Hydraulic Brake Components

- 81-950-016 Mico Brake Service Procedures

- 81-460-159 Mico Hydraulic Brake Valve

- 8497 System Operation Manual

- TESTING & ADJUSTING

- TROUBLE SHOOTING

- TRANSMISSION & TORQUE CONVERTER

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- HOW THE UNITS OPERATE

- SECTIONAL VIEWS AND PARTS IDENTIFICATION

- DISASSEMBLY OF TRANSMISSION

- CLUTCH DISASSEMBLY

- CLEANING AND INSPECTION

- REASSEMBLY OF TRANSMISSION

- SERVICING MACHINE AFTER TRANSMISSION OVERHAUL

- TOWING OR PUSH STARTING

- SPECIFICATIONS AND SERVICE DATA

- LUBRICATION

- TROUBLESHOOTING GUIDE

- TYPICAL TWO AND THREE SPEED POWER FLOW

- PRESSURE CHECK POINTS

- CLUTCH AND GEAR ARRANGEMENT

- DRIVE PLATE INSTALLATION

- TRANSMISSION TO ENGINE INSTALLATION PROCEDURE

- SPEED SENSOR BUSHING INSTALLATION

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- MISCELLANEOUS

- OPERATOR INSTRUCTIONS & LUBRICATION

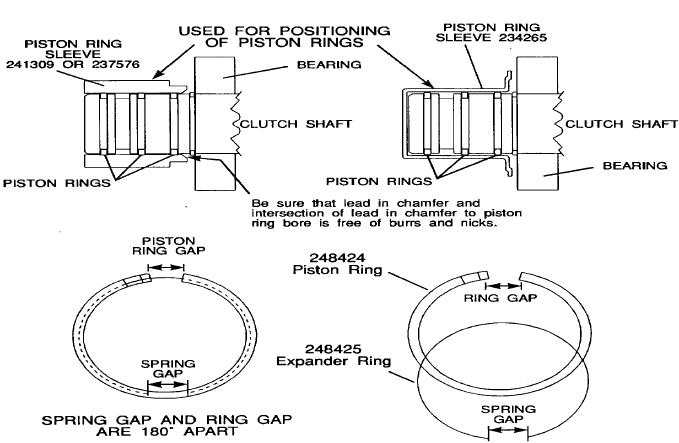

PROPER INSTALLATION OF TEFLON PISTON RING AND PISTON RING EXPANDER SPRINGS

NOTE: NOT ALL TRANSMISSIONS WILL HAVE TEFLON PISTON RINGS AND EXPANDER SPRINGS

Fill the oil sealing ring grooves with a good grade of grease, this will help stabilize the teflon ring and expander spring in the ring

groove for installation.

Position the expander spring in the inner groove of the new piston ring, with the expander spring gap 180° from the hook joint gap

of the piston ring.

Carefully position the piston ring and expander spring on the clutch shaft in the inner most ring groove. Hook the piston piston ring

joint.

Repeat steps 1, 2 and 3 for the remaining ring or rings making certain all hook joints are fastened securely.

Apply a heavy coat of grease to the outer diameter of the rings and clutch shaft. Center the piston ring’s in the ring groove.

Before installing the clutch assembly in the front cover or converter housing it is recommended a piston ring sleeve P/N’s 241309,

237576 or 234265 be used to center all of the piston rings in their respective ring grooves. Use extreme caution to not damage

piston rings when installing the clutch shaft in the front transmission cover or converter housing.

1.

2.

3.

4.

5.

6.

-50-