Service Manual User Manual

Table Of Contents

- 9020-7317 534B SERVICE MANUAL

- OPERATOR INSTRUCTIONS & LUBRICATION

- 8496 Operation & Lubrication Manual

- 8366 Operation & Lubrication Manual

- IMPORTANT SAFETY NOTICE

- INTRODUCTION

- SAFETY HIGHLIGHTS

- OPERATOR'S CAB

- CONTROL & INSTRUMENT IDENTIFICATION

- CHECKS & SERVICES BEFORE STARTING ENGINE

- ENGINE OPERATION

- WARM UP & OPERATIONAL CHECKS

- BRAKE SYSTEM

- STEERING SYSTEM

- DRIVE TRAIN

- MATERIAL HANDLING

- OPERATING PROCEDURES & TECHNIQUES

- PARKING

- STORAGE

- LUBRICATION & MAINTENANCE DIAGRAM

- 28327 Preventive Maintenance Chart

- HYDRAULIC SYSTEM

- 8497 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKE

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMP

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUIT

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUIT

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 8369 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKES

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMPS

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUITS

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUITS

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 81-515-009 Mico Sliding Caliper Disc Brakes Service Manual

- 81-600-001 Mico Guidelines for Installing Hydraulic Brake Components

- 81-950-016 Mico Brake Service Procedures

- 81-460-159 Mico Hydraulic Brake Valve

- 8497 System Operation Manual

- TESTING & ADJUSTING

- TROUBLE SHOOTING

- TRANSMISSION & TORQUE CONVERTER

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- HOW THE UNITS OPERATE

- SECTIONAL VIEWS AND PARTS IDENTIFICATION

- DISASSEMBLY OF TRANSMISSION

- CLUTCH DISASSEMBLY

- CLEANING AND INSPECTION

- REASSEMBLY OF TRANSMISSION

- SERVICING MACHINE AFTER TRANSMISSION OVERHAUL

- TOWING OR PUSH STARTING

- SPECIFICATIONS AND SERVICE DATA

- LUBRICATION

- TROUBLESHOOTING GUIDE

- TYPICAL TWO AND THREE SPEED POWER FLOW

- PRESSURE CHECK POINTS

- CLUTCH AND GEAR ARRANGEMENT

- DRIVE PLATE INSTALLATION

- TRANSMISSION TO ENGINE INSTALLATION PROCEDURE

- SPEED SENSOR BUSHING INSTALLATION

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- MISCELLANEOUS

- OPERATOR INSTRUCTIONS & LUBRICATION

To Engage Rear Driving Hubs: Repeat procedure.

NOTE: If machine is moved with keeper pin plate

removed, input shaft pin will pop out.

Hydraulic flow to rear axle drive motors is

controlled electrically. An automatic reset type

breaker is included to prevent damage from

overload. If circuit breaker trips (opens) rear

axle drive will be inoperative for approximately

ten seconds until breaker resets. Notify

maintenance personnel if circuit breaker trips

repeatedly.

To determine whether circuit breaker has tripped,

attempt to move machine using inching travel. If

machine does not respond to inching travel pedal

circuit breaker is open.

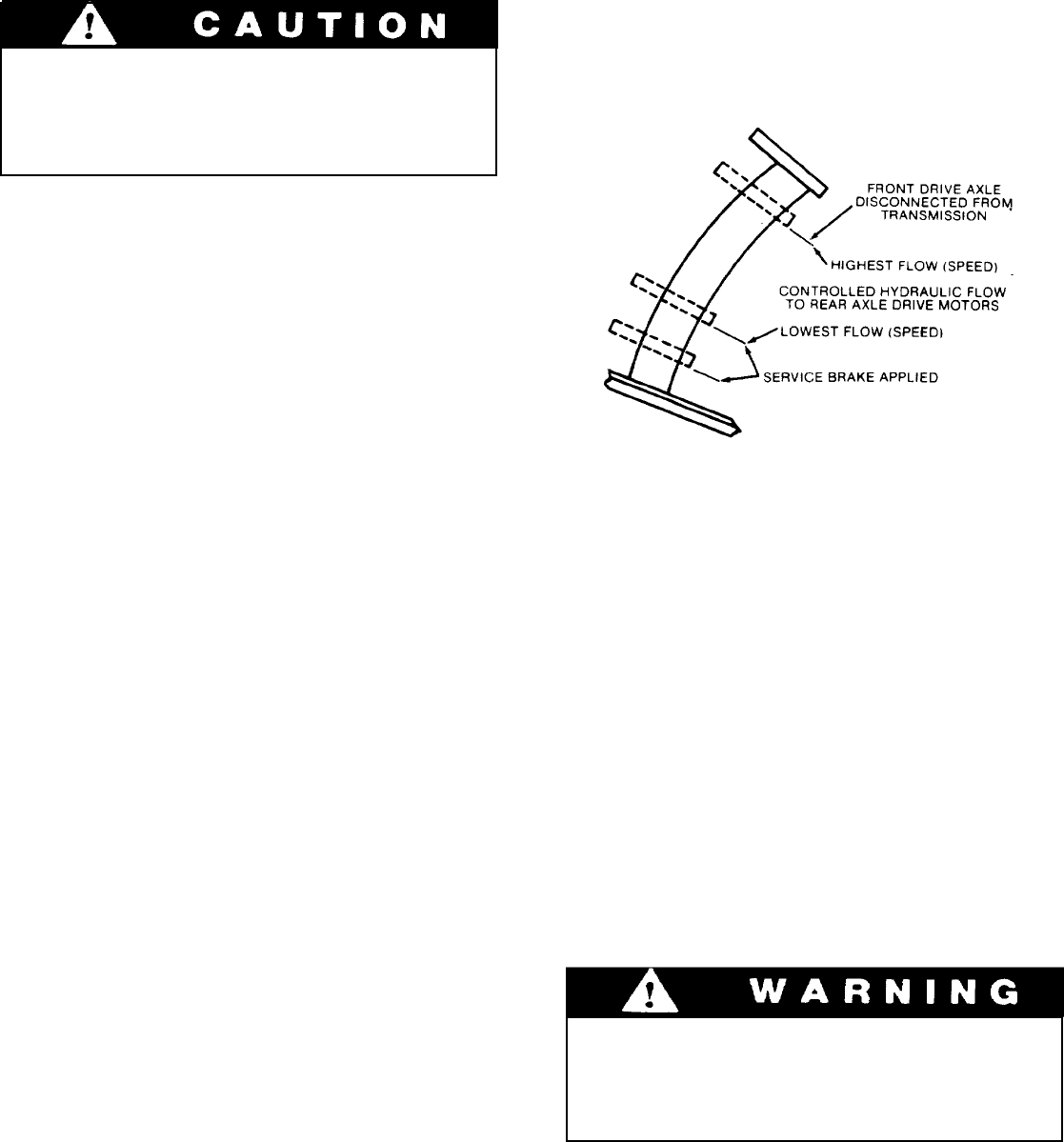

Inching Travel

Inching travel is provided to permit very slow travel

while maintaining high engine speed for other

functions. Because inching travel depends on

hydraulic flow to rear axle drive motors, inching

travel functions only in first and second gears. There

is no hydraulic flow to drive motors in third gear.

Inching travel is controlled by the service

brake/inching travel pedal. This pedal has three

separate functions:

Rear Driving Axle

The rear driving axle includes planetary hubs which

are powered by hydraulic motors mounted on the

inner face of the hubs. Hydraulic flow to drive

motors is provided only in first and second gear

speed ranges. Drive motors are free-floating in third

gear.

Continuous driving for two miles or more

in third gear, with rear driving hubs

engaged, can damage hydraulic drive

motors.

To Disengage Rear Driving Hubs:

Apply parking brake and remove key from

ignition switch.

Remove thumb scre

ws from keeper pin plate.

Remove and rotate plate per photo on pg. 6 (cup

out - engaged - cup in - disengaged).

Secure plate using thumb screws.

Repeat procedure for other hub.

1.

2.

3.

4.

5.

It disconnects front drive axle from

transmission.

It controls hydraulic flow to rear axle drive

motors (hydraulic flow equals speed).

It applies service brake.

1.

2.

3.

As illustrated, the three functions occur in sequence

as pedal is depressed from top to bottom of stroke.

To Engage Inching Travel:

Practice inching/braking in a safe, open

area until you are thoroughly familiar with

response of machine to pedal travel

1.

2.

3.

Depress service brake/inching travel pedal

approximately 1-1/2 inches to disengage front

driving axle from transmission. At this point rear

drive motors are receiving full flow and travel

speed will not have changed.

Continue to depress pedal to reduce speed - the

more pedal travel, the less speed.

To stop, depress pedal fully.

OR

To resume normal travel release service brake/

inching travel pedal. Depress accelerator pedal to

attain appropriate speed.

12