Service Manual User Manual

Table Of Contents

- 9020-7317 534B SERVICE MANUAL

- OPERATOR INSTRUCTIONS & LUBRICATION

- 8496 Operation & Lubrication Manual

- 8366 Operation & Lubrication Manual

- IMPORTANT SAFETY NOTICE

- INTRODUCTION

- SAFETY HIGHLIGHTS

- OPERATOR'S CAB

- CONTROL & INSTRUMENT IDENTIFICATION

- CHECKS & SERVICES BEFORE STARTING ENGINE

- ENGINE OPERATION

- WARM UP & OPERATIONAL CHECKS

- BRAKE SYSTEM

- STEERING SYSTEM

- DRIVE TRAIN

- MATERIAL HANDLING

- OPERATING PROCEDURES & TECHNIQUES

- PARKING

- STORAGE

- LUBRICATION & MAINTENANCE DIAGRAM

- 28327 Preventive Maintenance Chart

- HYDRAULIC SYSTEM

- 8497 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKE

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMP

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUIT

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUIT

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 8369 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKES

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMPS

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUITS

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUITS

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 81-515-009 Mico Sliding Caliper Disc Brakes Service Manual

- 81-600-001 Mico Guidelines for Installing Hydraulic Brake Components

- 81-950-016 Mico Brake Service Procedures

- 81-460-159 Mico Hydraulic Brake Valve

- 8497 System Operation Manual

- TESTING & ADJUSTING

- TROUBLE SHOOTING

- TRANSMISSION & TORQUE CONVERTER

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- HOW THE UNITS OPERATE

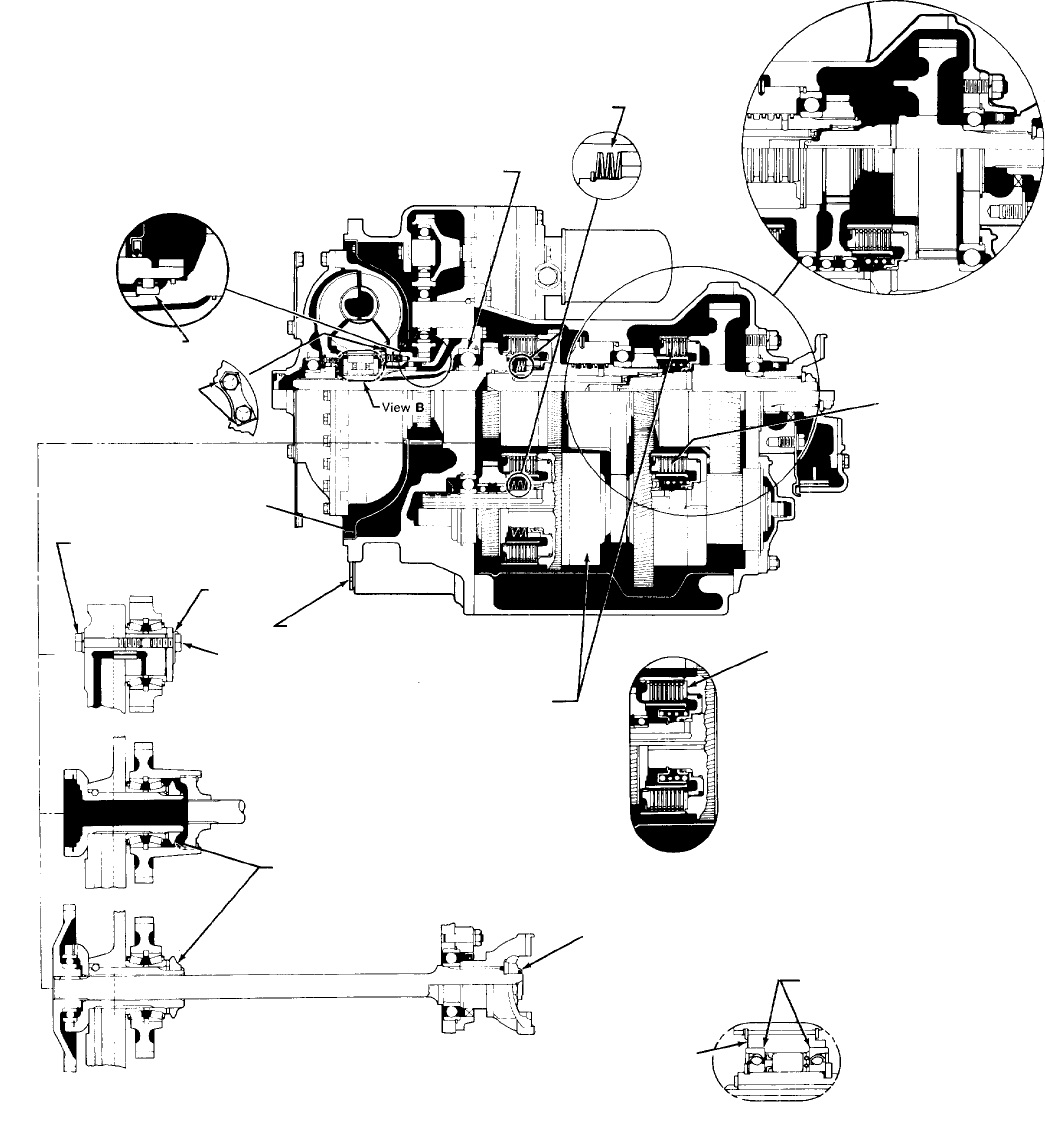

- SECTIONAL VIEWS AND PARTS IDENTIFICATION

- DISASSEMBLY OF TRANSMISSION

- CLUTCH DISASSEMBLY

- CLEANING AND INSPECTION

- REASSEMBLY OF TRANSMISSION

- SERVICING MACHINE AFTER TRANSMISSION OVERHAUL

- TOWING OR PUSH STARTING

- SPECIFICATIONS AND SERVICE DATA

- LUBRICATION

- TROUBLESHOOTING GUIDE

- TYPICAL TWO AND THREE SPEED POWER FLOW

- PRESSURE CHECK POINTS

- CLUTCH AND GEAR ARRANGEMENT

- DRIVE PLATE INSTALLATION

- TRANSMISSION TO ENGINE INSTALLATION PROCEDURE

- SPEED SENSOR BUSHING INSTALLATION

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- MISCELLANEOUS

- OPERATOR INSTRUCTIONS & LUBRICATION

All lead in chamfers for oil seals, piston rings,

& “0” rings must be smooth and free from burrs.

Inspect at assembly,

Lubricate all piston ring grooves & “0” rings

with oil before assembly.

Apply very light coat of Permatex No. 2 to

0 D. of all oil seals before assembly.

After assembly of parts using loctite or Permatex

there must not be any free or excess material

that could enter the oil circuit.

Apply a light coal of #92 loctite to all

pipe plugs.

Apply a thin coating of grease between seal lips

on lip type seals prior to assembly.

1.

2.

3.

4.

5.

6.

Bearing part No. must

be “OUT”. Chamber

must be “IN”.

Torque capscrews & bend

corners of lock tab up

against bolt hex flats

as shown.

Press baffle to shoulder

in converter housing. Press

on outside diameter only.

Torque

58 to 64 Lbs. - Ft.

[78,7 - 86,7 N•m]

Bend lock tabs

at ass’y

Torque

58 to 64 Lbs. Ft.

[78.7 - 86,7 N•m]

Standard Idler Gear

Idler gear with

turbine driven P.T.O.

Must be assembled with

bearing number inside

Viewed from this direction

outer race freewheels

clockwise

View B

Figure I

Tighten nut 200 to 250 Lbs. - Ft. [271,2 - 339,0 N•m]

Tighten nut 200 to 300 Lbs. Ft. [271,2 - 406,7 N•m]

and stake securely in place.

Special steel backing

plate to be used with

reduced size pistons only.

Forward and reverse clutches with

reduced size pistons only.

1 Outer steel backing plate

and disc assembly.

7 Outer steel discs.

8 Inner friction discs.

Start with outer steel backing

plate next to piston, then (1)

inner friction disc then (1)

outer steel disc. Alternate

steel and friction discs until

proper amount of discs are installed.

Idler gear with

engine driven P.T.O.

Forward & Reverse Clutch Return Springs

Concave side of first belleville spring to be

placed against clutch piston. Remaining four

springs of each clutch to be stacked

alternately reversed as shown.

Special bearing-ball

loading notches

opposite snap ring.

Tighten oil screen assembly

10 to 15 Lbs. Ft. [13,16 - 20,3 N•m]

Two clutches (2nd & 3rd)

6 Outer steel discs

6 Inner friction discs

Start with outer steel disc.

alternate friction and steel

8 - Outer steel plates

8 - Inner bronze plates

Alternately assemble

starting with outer

steel plate.

2 - SPEED

3 - SPEED