Service Manual User Manual

Table Of Contents

- 9020-7317 534B SERVICE MANUAL

- OPERATOR INSTRUCTIONS & LUBRICATION

- 8496 Operation & Lubrication Manual

- 8366 Operation & Lubrication Manual

- IMPORTANT SAFETY NOTICE

- INTRODUCTION

- SAFETY HIGHLIGHTS

- OPERATOR'S CAB

- CONTROL & INSTRUMENT IDENTIFICATION

- CHECKS & SERVICES BEFORE STARTING ENGINE

- ENGINE OPERATION

- WARM UP & OPERATIONAL CHECKS

- BRAKE SYSTEM

- STEERING SYSTEM

- DRIVE TRAIN

- MATERIAL HANDLING

- OPERATING PROCEDURES & TECHNIQUES

- PARKING

- STORAGE

- LUBRICATION & MAINTENANCE DIAGRAM

- 28327 Preventive Maintenance Chart

- HYDRAULIC SYSTEM

- 8497 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKE

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMP

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUIT

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUIT

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 8369 System Operation Manual

- COVER

- NOMENCLATURE

- CAB CONTROLS AND GAGES

- ENGINE

- MAIN FRAME

- FRONT DRIVE AXLE

- DRIVE SHAFT

- REAR DRIVE AND STEERING AXLE

- TIRES

- TRANSMISSION & TORQUE CONVERTER

- STEERING CIRCUIT

- HYDRAULIC SERVICE BRAKES

- MECHANICAL PARKING BRAKE

- HYDRAULIC SYSTEM

- HYDRAULIC RESERVOIR

- HYDRAULIC PUMPS

- MAIN CONTROL VALVE BANK

- MAIN PUMP CIRCUITS

- PILOT PUMP CIRCUIT

- HYDRAULIC CYLINDERS

- SWAY CIRCUIT

- LIFT CIRCUIT

- FRONT & REAR WHEEL DRIVE

- FORWARD / REVERSE LEVER (Neutral)

- FORWARD / REVERSE LEVER (Activated)

- INCHING

- TILT & COMPENSATING CIRCUITS

- OIL COOLER CIRCUIT

- CROWD (Boom In-Out) CIRCUITS

- AUXILIARY HYDRAULIC SYSTEM

- BOOM SECTIONS

- BOOM SLIDER PADS

- BOOM CROWD (IN-OUT) MOVEMENT

- MANUAL "QUICK-SWITCH" ASSEMBLY

- ELECTRICAL

- FUEL TANK

- 81-515-009 Mico Sliding Caliper Disc Brakes Service Manual

- 81-600-001 Mico Guidelines for Installing Hydraulic Brake Components

- 81-950-016 Mico Brake Service Procedures

- 81-460-159 Mico Hydraulic Brake Valve

- 8497 System Operation Manual

- TESTING & ADJUSTING

- TROUBLE SHOOTING

- TRANSMISSION & TORQUE CONVERTER

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- HOW THE UNITS OPERATE

- SECTIONAL VIEWS AND PARTS IDENTIFICATION

- DISASSEMBLY OF TRANSMISSION

- CLUTCH DISASSEMBLY

- CLEANING AND INSPECTION

- REASSEMBLY OF TRANSMISSION

- SERVICING MACHINE AFTER TRANSMISSION OVERHAUL

- TOWING OR PUSH STARTING

- SPECIFICATIONS AND SERVICE DATA

- LUBRICATION

- TROUBLESHOOTING GUIDE

- TYPICAL TWO AND THREE SPEED POWER FLOW

- PRESSURE CHECK POINTS

- CLUTCH AND GEAR ARRANGEMENT

- DRIVE PLATE INSTALLATION

- TRANSMISSION TO ENGINE INSTALLATION PROCEDURE

- SPEED SENSOR BUSHING INSTALLATION

- SM HR 182-3 Clark 18000 Series Powershift Transmission

- MISCELLANEOUS

- OPERATOR INSTRUCTIONS & LUBRICATION

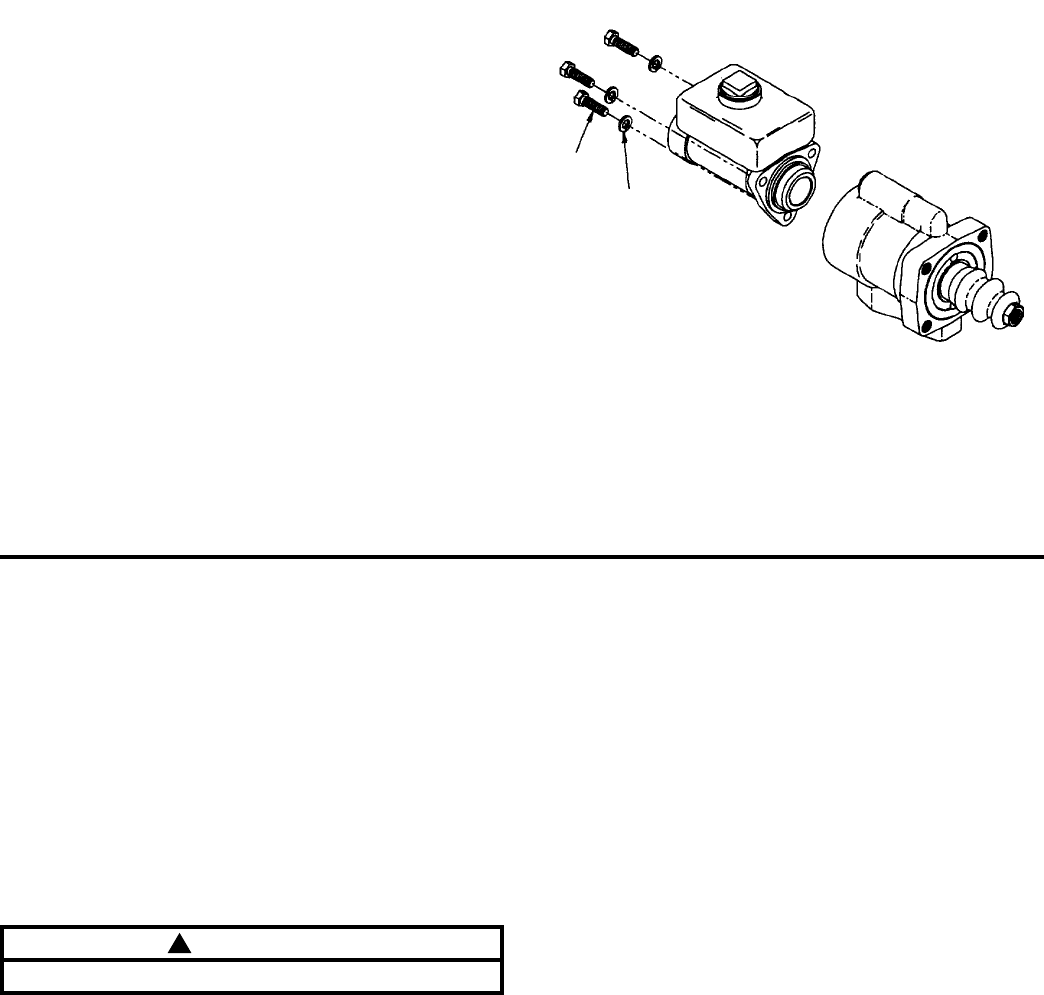

REMOVING BRAKE VALVE FROM

VEHICLE AND SEPARATING SECTIONS

(Refer to Figures 1 & 3)

Remove Brake Valve from vehicle by disconnecting

necessary fluid lines, disconnecting push rod and

removing mounting bolts. Drain fluid from assembly.

Separate Master Cylinder Section from Power Assist

Section by removing three cap screws and three

lock washers.

CONNECTING SECTIONS AND

MOUNTING BRAKE VALVE ON VEHICLE

(Refet to Figures 1 & 3)

Attach Master Cylinder Section to Power Assist

Section with three cap screws and three lock washers.

Torque 29.8-36.6 Nm (22-27 lbs-ft).

Install unit on vehicle and connect fluid lines. Connect

push rod. Bleed system of air. Tighten fittings if leaks

occur. Make several applications to be sure brake valve

is working properly. NOTE: All fittings must be

inspected for leaks and tightened if leaks occur.

MASTER CYLINDER DISASSEMBLY

(Refer to Figures 1 & 4)

Remove filler plug (15) and gasket (14) from housing

(2).

Drain fluid from unit before disassembling.

Place master cylinder section in a soft jawed vise in

a vertical position with end plug (11) facing up.

Remove adapter (13) and gasket (12) from end plug

(11). NOTE: Not all models use adapter (13) or

gasket (12).

Remove end plug (11) from housing (2).

CAUTION

End plug (11) is under tension of spring (7).

Remove check valve (8), seat (9) and o-ring (10)

from end plug (11).

Remove spring (7) from housing. Remove retainer

(6) from spring (7).

Use a wooden dowel to push cup (5), piston

assembly (4) and piston assembly (3) out of end

plug (11) end of housing (2). NOTE: Be careful not

to scratch or mar housing bore.

Remove retaining ring (1) from housing (2).

1.

2.

1.

2.

cap screws

lock washers

MASTER CYLINDER

SECTION

POWER ASSIST

SECTION

FIGURE 3

1.

2.

3.

4.

5.

!!

!!

!

6.

7.

8.

9.

MASTER CYLINDER ASSEMBLY

(Refer to Figures 1 & 4)

Use only automotive brake fluid in Master Cylinder

Section.

LUBRICATE ALL RUBBER COMPONENTS FROM

REPAIR KIT WITH CLEAN TYPE FLUID USED IN

THE SYSTEM.

Clean all parts thoroughly before assembling.

Install new retaining ring (1) in housing (2).

Carefully install new piston assembly (3), new piston

assembly (4) and new cup (5) in end plug (11) end

of housing. Note direction of piston assemblies (3 &

4) and cup (5). NOTE: Be careful not to scratch

or mar housing bore.

Install new retainer (6) on spring (7). Install spring

(7) in housing, retainer end first.

Install new o-ring (10), new seat (9) and new check

valve (8) on end plug (11). Install end plug (11) into

housing. Torque end plug (11) 61.0-81.4 Nm

(45-60 lbs-ft).

Install new gasket (12) and adapter (13) in end plug

(11). Torque adapter (13) 47.5-54.2 Nm (35-40 lbs-ft).

NOTE: Not all models use gasket (12) or adapter

(13).

Remove master cylinder section from soft jawed

vise.

Install new gasket (14) and filler plug (15) on hous-

ing (2).

1.

2.

3.

4.

5.

6.

7.

8.