Manual

Table Of Contents

- 9103-4314 534B-9 OPERATION & LUBRICATION MANUAL

- Important Safety Notice

- Introduction

- Nomenclature

- Safety Highlights

- Decals

- Operator's Cab

- Control and Instrument Identification

- Checks and Services Before Starting Engine

- Engine Operation

- Warm Up & Operational Checks

- Brake System

- Steering System

- Drive Train

- Leveling the Handler

- Operating Procedures & Techniques

- Attachments

- Recommended Lubricants & Capacities

- Torque Chart

- Lubrication & Maintenance Diagram

- Moving Handler in Emergency

- Hand Signals

Operate unit until hydraulic oil reaches normal

operating temperature.

Apply parking brake and observe hydraulic filter

by-pass indicator with engine running at full

throttle. Replace filter elements if necessary.

Obtain a container to receive waste oil and a

CLEAN container to receive oil sample.

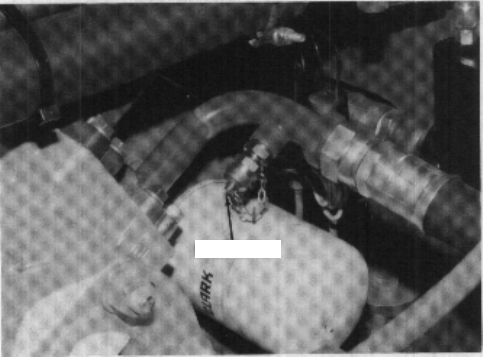

With gage removed from hose, attach mini-

check and hose to test port near main hydraulic

pump. Hose end must be positioned in waste oil

container.

Allow at least one pint of oil to flow into waste oil

container to eliminate any contamination from

hose.

Move hose to CLEAN container to collect sample

for analysis.

Return hose to waste oil container and disconnect

adapter from mini-check test port.

Cover sample container immediately with

CLEAN cap.

Stop engine and check oil level in reservoir and

replenish as required.

Contact your Gradall Distributor for information

concerning oil analysis.

Oil sample containers are available from several

sources:

Oil companies

Oil suppliers

Sampling labs

Obtaining Hydraulic Oil Sample for Analysis

1.

2.

3.

5.

6.

7.

8.

9.

10.

4.

l

l

l

34

OIL CLEANLINESS IS A MUST.

TEST PORT