User's Manual

Table Of Contents

2 3A1302D

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

1. Relieve pressure. See Pressure Relief Procedure

in manual 3A1214.

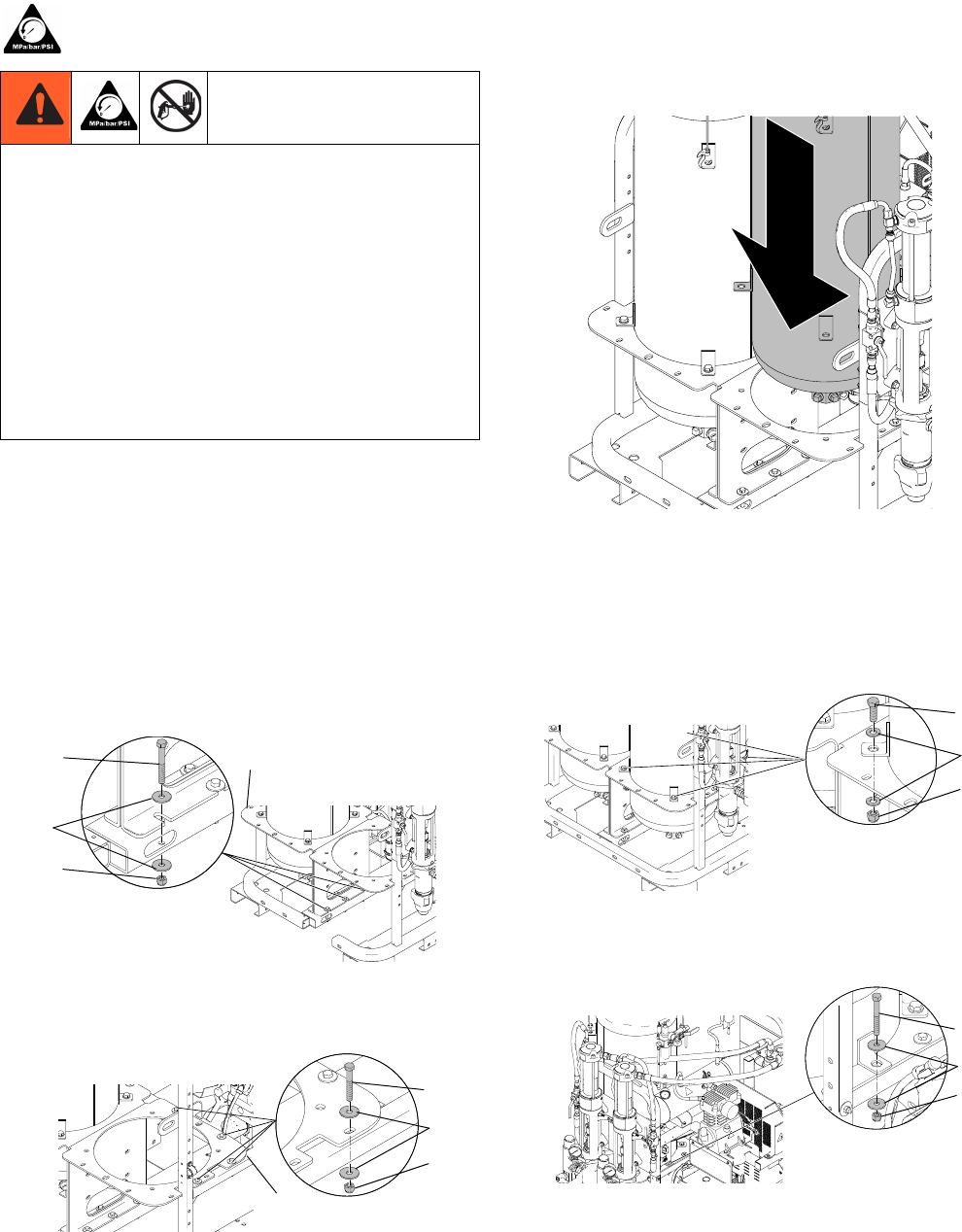

Second Bead Tank Installation

1. Place bead tank mounting bracket (2) into position

on RoadPak frame.

2. Install three bolts (16) and washers (17) on bottom

of bracket (2). Thread nuts (15) onto bolts and

torque to 15 ft-lb (20.3 N•m).

3. Install four bolts (18) and washers (17) to top of

bracket (2). Thread nuts (15) onto bolts and torque

to 15 ft-lb (20.3 N•m).

NOTE: If installing to accessory frame kit (24H585)

install four bolts (18) and washers (17) to top of

bracket (2). Thread nuts (15) onto bolts and torque

to 15 ft-lb (20.3 N•m).

4. Use hoist (or other lifting equipment) to lift bead tank

(1) and lower it into tank mounting bracket (2).

NOTE: Make sure bead tank is positioned with air

regulator inlet facing toward inside of RoadPak.

5. Install four bolts (18) and washers (17) at each cor-

ner bead tank mount. Thread nut (15) onto bolts and

torque to 27 ft-lb (36.6 N•m).

6. Install bolt (12) and washers (13) into center bead

tank mount. Thread nut (14) onto bolt and torque to

15 ft-lb (20.3 N•m).

The system pressure must be manually relieved to pre-

vent the system from starting or spraying accidentally.

Fluid under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of an

injury from injection, splashing fluid, or moving parts,

follow the Pressure Relief Procedure in manual

3A1214 whenever you:

• are instructed to relieve the pressure

• stop spraying

• check or service any of the system equipment

• install or clean the spray tip

ti16797a

16

17

15

2

ti16796a

18

17

15

2

ti16798a

ti16799a

18

17

15

ti16800a

12

13

14