User's Manual

Installation and Setup

10 3A0416C

Installation and Setup

Determining Correct Mounting

Method

NOTE:

• Direct mounting should be used for lubrica-

tion points that are easily accessible.

• Remote mounting is recommended if you

answer YES to any of the questions below.

1. Is the ambient temperature at the lubrica-

tion point higher than +50°C (122°F)?

2. Is it necessary to remove protective

screens, walls or other types of protection

in order to reach the lubrication point?

3. Is the lubrication point exposed to high

vibrations?

4. Is it difficult to access the lubrication point

during operation of the machine?

5. Is the lubrication point exposed to any of

the following:

• water jets for high-pressure cleaning

machines?

• corrosive chemicals?

• extreme temperature?

• falling materials?

Preparing Lubricator for

Installation

The lubricator has a self-protection mecha-

nism which shuts off the drive unit at counter

pressures higher than 5 bar (72.5 psi). Most

bearings require 0.5 - 2 bar (7.2 to 29 psi)

pressure (without tubes, extensions, angles,

etc.).

Use the following procedure to check the

counter pressure of the application prior to

installation.

NOTE:

• Be sure to use a lubricant cartridge that

contains the same grease used in the

application.

• The best measurement results are

achieved during operation.

Checking the Counter Pressure

1. Clean the lubrication point to remove any

potential contaminants.

2. Install reducers, extensions, grease line,

etc. (if necessary).

3. Prime the grease line and all accessories

with the same grease that is contained in

the lubricator. (See Parts, page 22 for a

complete list of available grease car-

tridges).

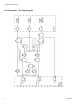

4. Remove the plug (A).

5. Install lubricator unit

into adapter (B).

6. Screw a pressure manometer into the lubri-

cation point (dd) (F

IG. 1, page 11).

A

B