User's Manual

Table Of Contents

Troubleshooting

54 333347F

Flush Pressure Relief Valve

Perform this procedure when directed in the Trouble-

shooting table.

1. With the system active at the required adhesive

temperature, set the air motor air pressure to 20 psi

(140 kPa, 1.4 bar).

2. Remove the air line (36) from the pressure relief

valve.

3. Plug air line and allow the air motor to cycle.

4. Re-connect air line to relief valve and check whether

the system will stall.

5. If system still does not stall, purge ten pump cycles

of material through one applicator.

6. Repeat this entire procedure until no additional air is

expelled from the applicator.

Check the Pump Air Solenoid Operation

Perform this procedure when directed in the Trouble-

shooting table.

NOTE: System must be up to operating temperature for

pump solenoid to trigger on.

1. If the heating system and pump is disabled,

press to enable the heaters and pump.

2. Wait for system to reach the temperature setpoints.

3. Set pump air pressure to 20 psi (140 kPa, 1.4 bar).

4. Remove the 3/8 in. OD air line from the air motor.

5. Verify that air is flowing through the air line.

6. If air is not flowing, check the wiring between J13

and the pump solenoid.

Check Heater Rod Resistance

Use the table to determine if heater elements need to be

replaced.

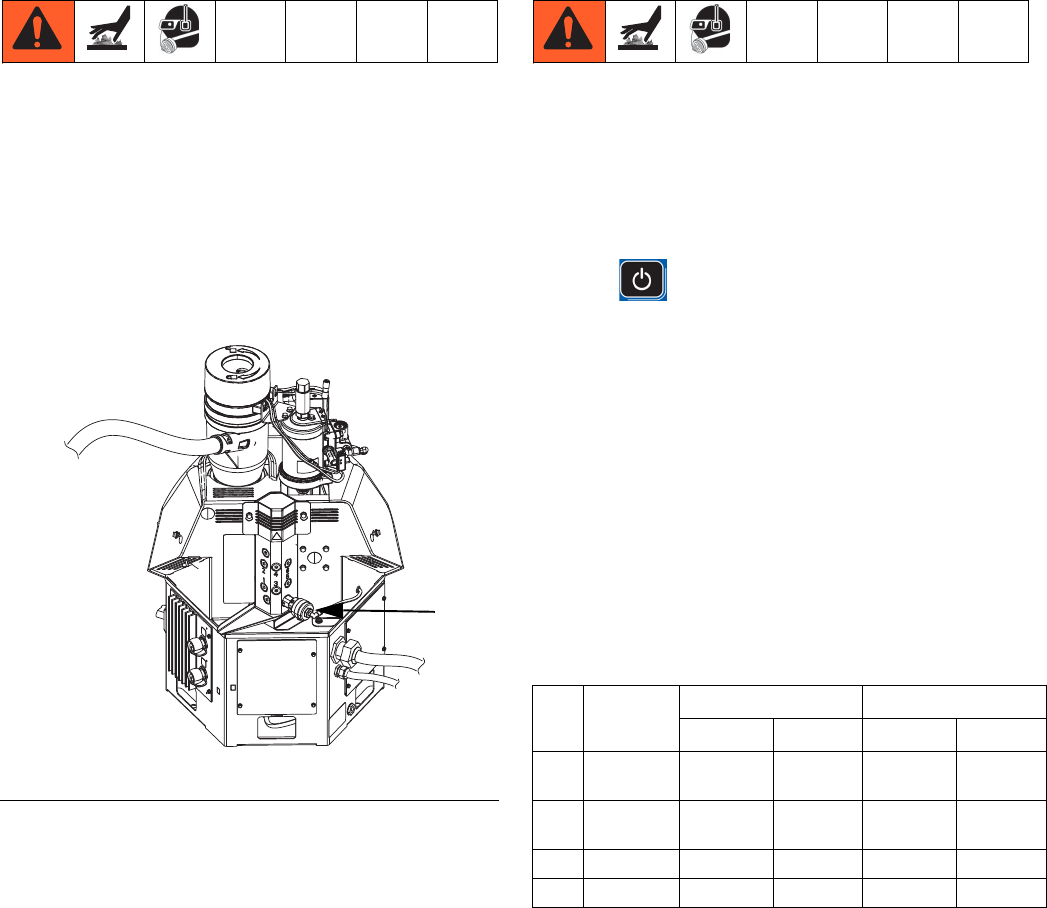

F

IG

. 28

WLD

36

Ref. Element

HM25 HM50

Wattage Ohms Wattage Ohms

208

Band

Heater

1250 43.5-48.5 2000 27-31

209

Melter

Rod

500 109-121 1500 36.5-40.5

210

Base Rod 1500 36.5-40.5 1000 54-61

210

Pump Rod 1500 36.5-40.5 1000 54-61